Waterproof method after the removal of the scaffolding wall device

A scaffolding and wall-connecting technology, which is applied to scaffolding accessories, house structure support, house structure support, etc., can solve problems such as unguaranteed bearing capacity, increased construction cost, and fire hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

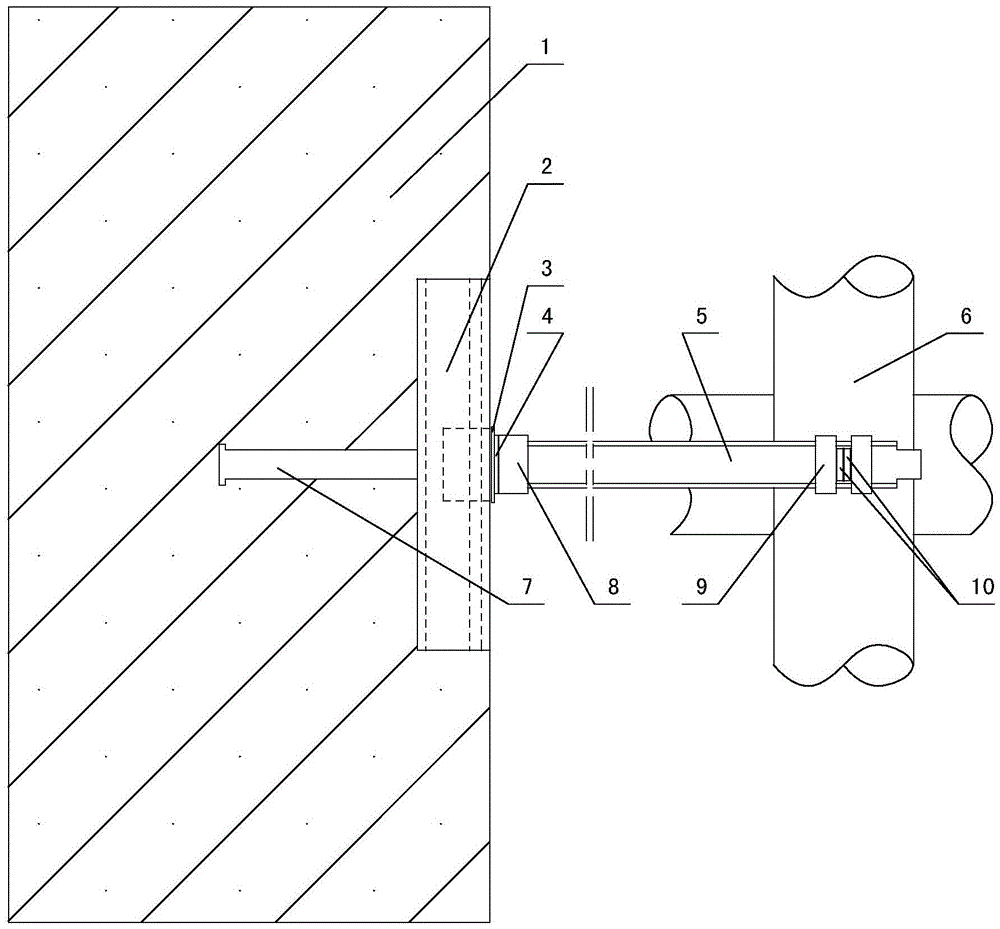

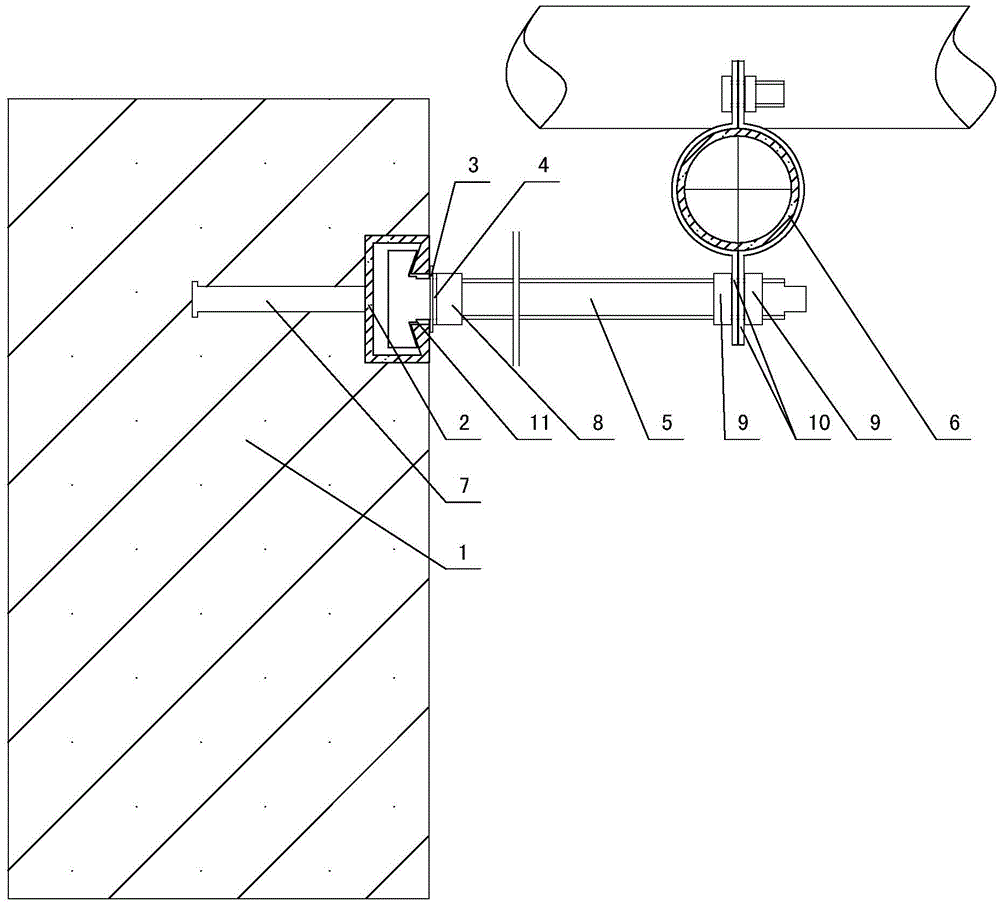

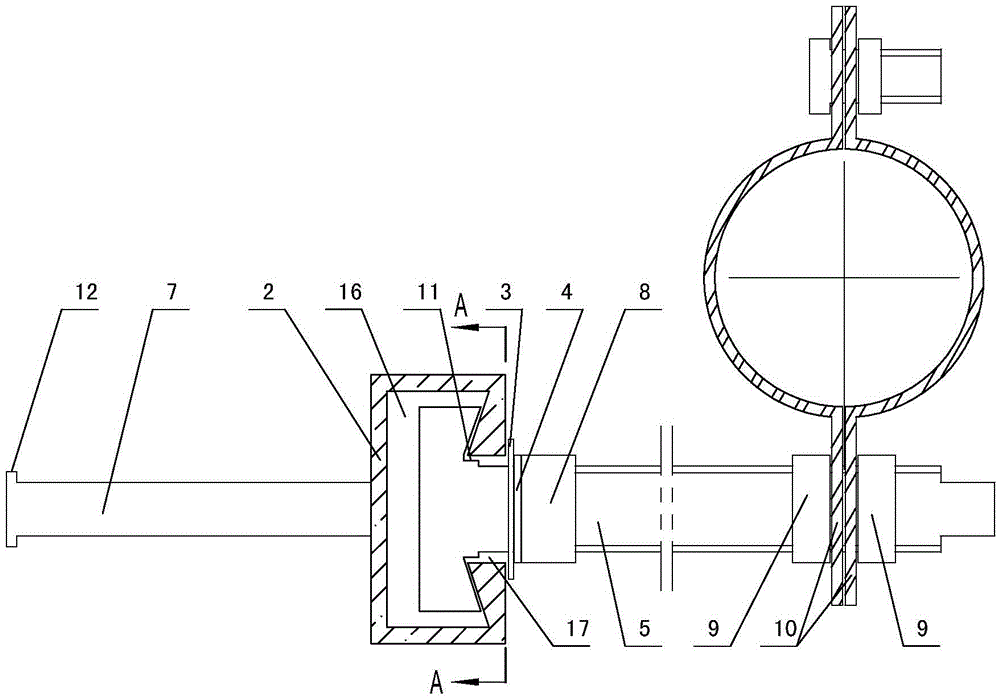

[0023] by Figure 1 ~ Figure 4 The shown schematic diagram of the structure of the scaffolding wall device shows that it includes an anchor 7 embedded in the wall 1 and a wall connecting member that connects the inner pole of the scaffold with the anchor 7 through a fastener 10. The wall connecting piece includes an embedded piece 2, a connecting wall tie rod 5 and a tie rod fastening nut 8. The embedded piece 2 is a vertically placed rectangular parallelepiped with a cavity 16 and has a side facing the outside of the wall 1 An elongated opening 17 running through the entire length. The anchor 7 is placed horizontally, and one end is welded to the flat end of the embedded part 2 facing the inner side of the wall 1. One end of the connecting wall tie rod 5 is a big end for limiting the position. The big end is slidably connected in the embedded part 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com