Waterproof structure for thin part at junction of steel latticed column and foundation slab and treatment method

A technology of steel lattice columns and foundation floor, which is applied in basic structure engineering, underwater structures, water conservancy projects, etc., can solve problems such as leakage around lattice columns, and achieve construction quality assurance, simple implementation, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

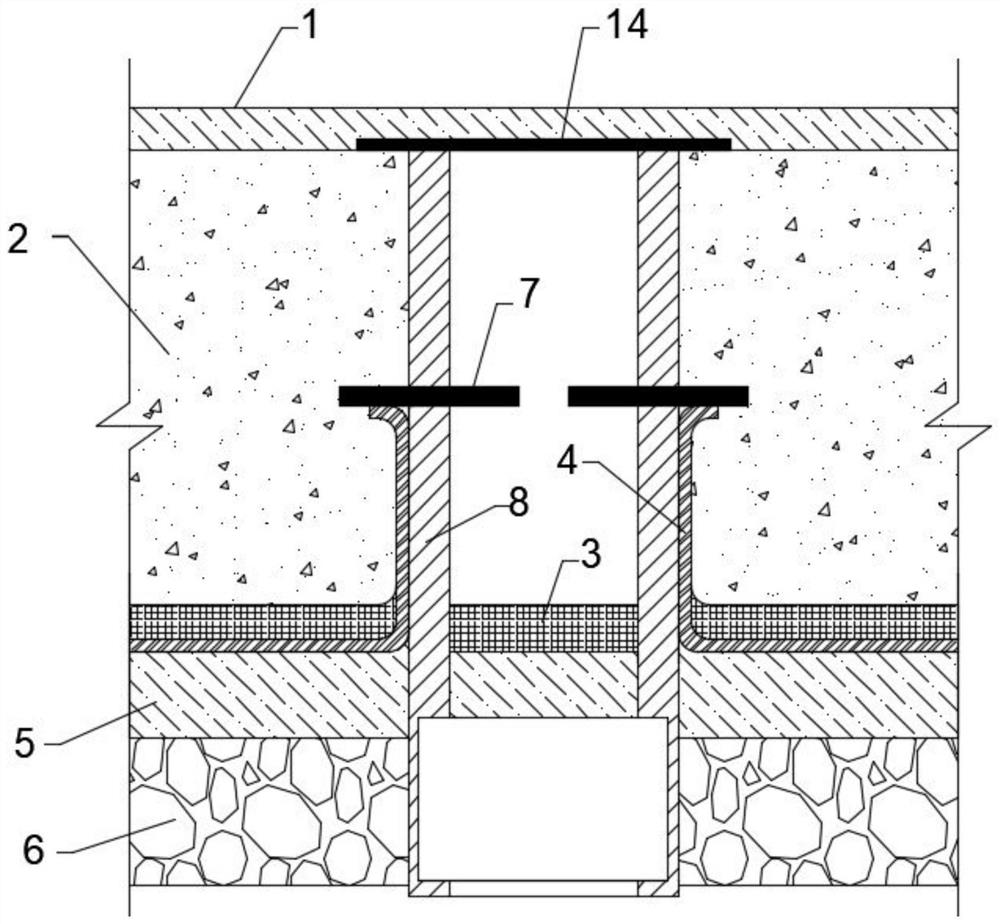

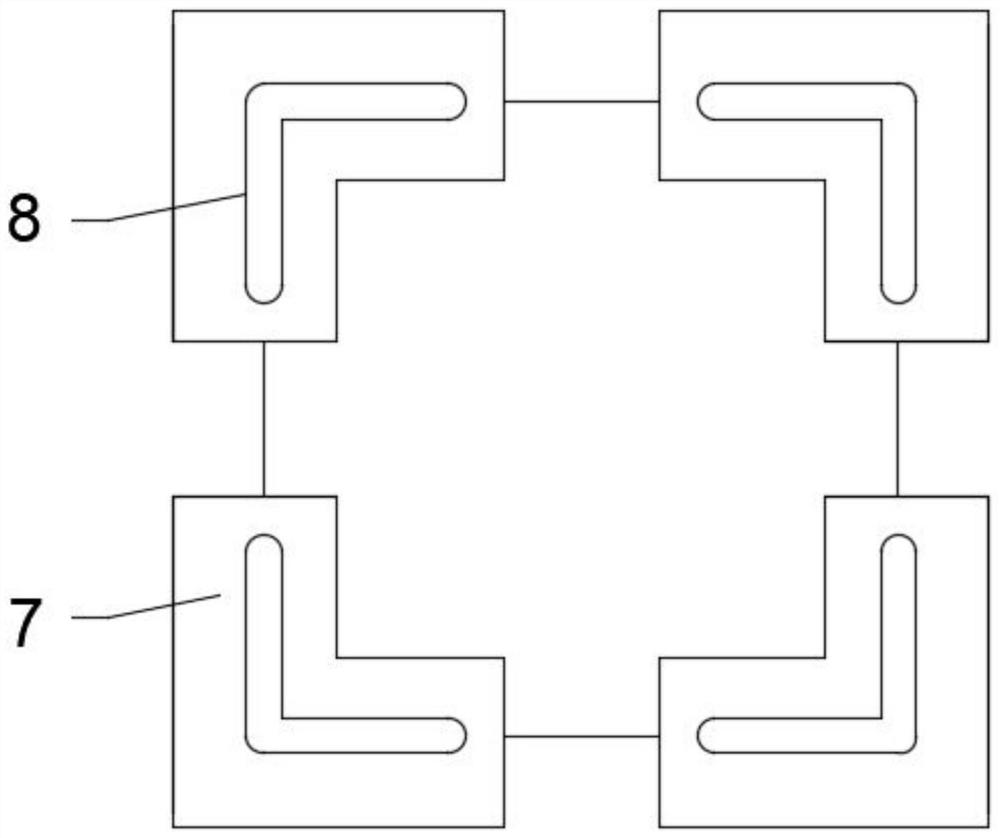

[0044] Such as Figure 1 to Figure 2 As shown, a detailed waterproof structure at the junction of a steel lattice column and a foundation floor, including a steel lattice column 8, including a building surface layer 1, a foundation floor layer 2, a waterproof protection layer 3, and a waterproof layer arranged in sequence from top to bottom 14. The concrete cushion 5 and the foundation 6, the top of the steel lattice column 8 is provided with a waterproof layer 2 14 and the lower surface of the waterproof layer 14 is flush with the building surface 1, and the upper surface of the steel lattice column 8 A water-stop flange 7 is provided, and the side of the waterproof layer 4 away from the waterproof protective layer 3 extends to the lower surface of the water-stop flange 7 and is bonded to each other, and the side wall of the waterproof layer 4 is connected to the steel lattice structure. Column 8 sidewalls are bonded. The periphery of the steel lattice column 1 is waterproof...

Embodiment 2

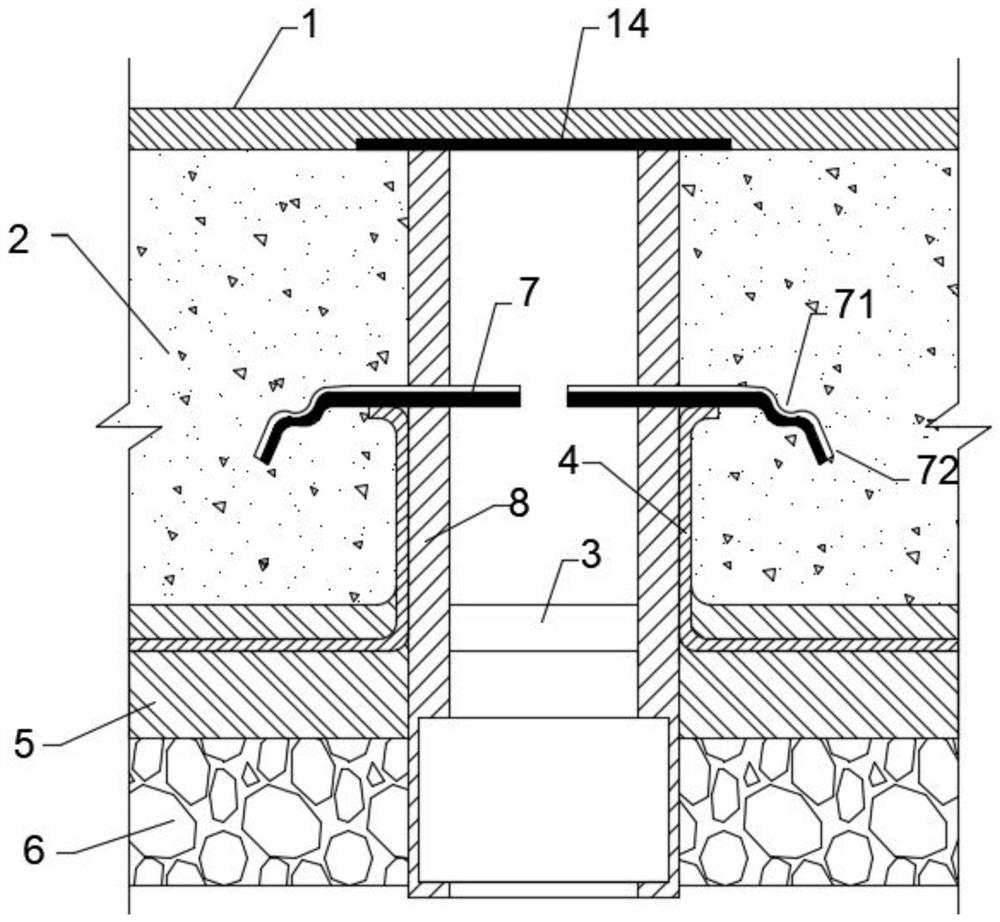

[0046] Such as image 3 As shown, on the basis of Example 1, the water-stop flange 7 is further improved on the waterproof effect, specifically: the water-stop flange 7 is located in the middle of the base floor layer 2, and the water-stop flange The component 7 includes a fixed part 71 , a water stop part 1 72 and a water stop part 2 73 integrally connected. Utilizing the design at the special position of the water-stop flange 7 can effectively ensure its construction efficiency and feasibility.

[0047]In a further preferred solution of this embodiment, the water stop part 1 72 and the fixed part 71 are set at an obtuse angle, and the angle between the water stop part 2 73 and the water stop part 1 72 is smaller than the water stop part 1 72 and the fixed part The angle between 71. The inclination angle of the water stop part 1 72 and the water stop part 71 is used to ensure its waterproof effect and achieve a double waterproof effect.

[0048] In a further preferred solu...

Embodiment 3

[0050] Such as image 3 As shown, a method for processing the detailed waterproof structure at the junction of the steel lattice column and the foundation floor includes the following steps:

[0051] First, select the water-stop flange 7, the main material of the steel lattice column 8 with a military width of each side is not less than 100mm, and the thickness is not less than 10mm, and then double-sided embroidery;

[0052] Secondly, double-sided welding is performed on the water-stop flange 7 and the steel lattice column 8, the height of the weld is not less than 8mm, and the anti-rust paint is painted on both sides, and the welding position is the center of the thickness of the foundation floor;

[0053] Thirdly, construct the concrete cushion layer 5, make connections around the steel lattice columns 8 and make arc angles;

[0054] Subsequently, the waterproof coiled material is finally constructed between the concrete cushion 5 and the steel lattice column 8 to make a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com