A plate processing mechanism

A processing mechanism and plate technology, applied in wood processing appliances, metal processing equipment, special forming/shaping machines, etc., can solve problems such as easy cuts and injuries to workers, and achieve the effect of strong functionality, accurate precision, and improved application value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

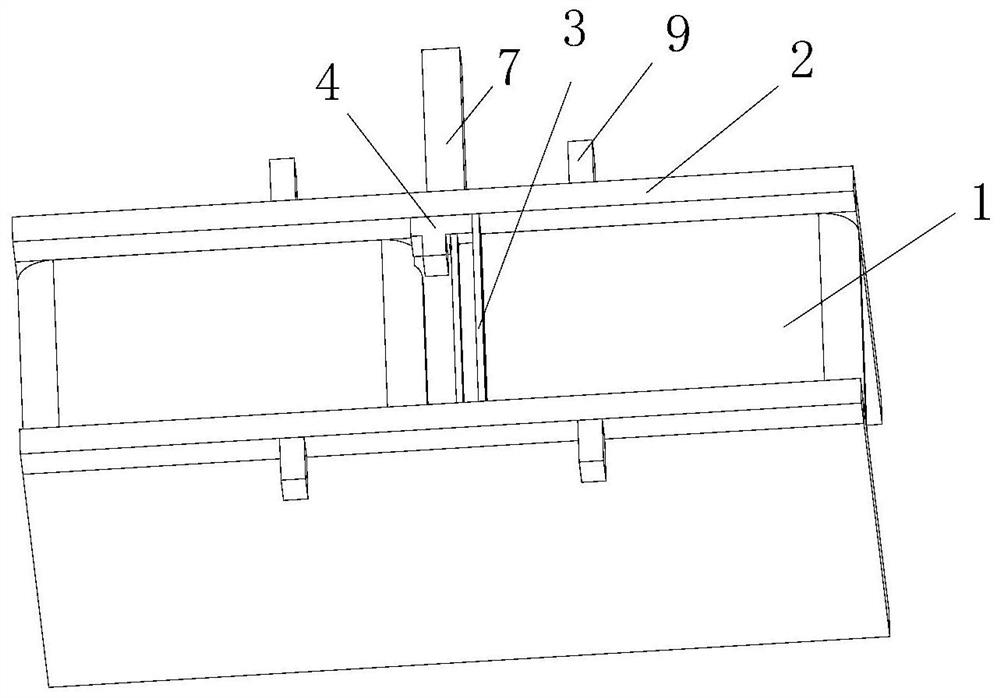

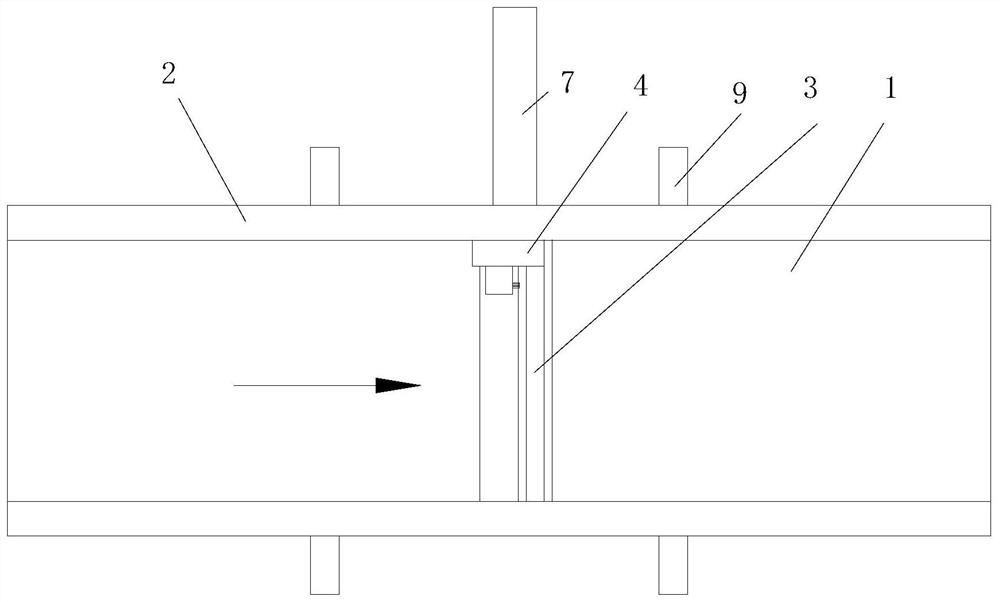

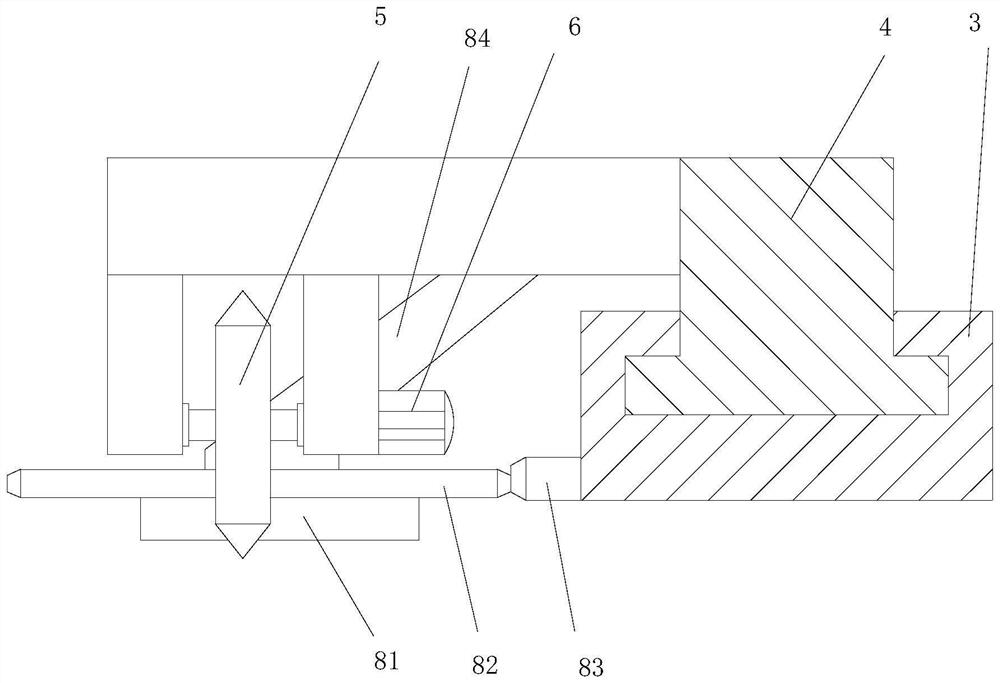

[0032] Attached below Figure 1-6 The present invention is further described with examples:

[0033] A plate processing mechanism, comprising a frame body 2 and a conveyor belt 1, the frame body 2 is provided with a cutting mechanism, the cutting mechanism comprises a cutting guide rail 3, and the cutting guide rail 3 is longitudinally arranged on the frame body 2 , the cutting guide 3 is slidably connected to the cutting base 4, the cutting base 4 is provided with a cutting blade 5, and the outer side of the cutting blade 5 is connected to a motor 6, and the motor 6 is arranged on the cutting base 4. The present invention solves the problem that warped flashes often appear on the edge of the cutting place in the process of plate cutting on the market, and workers are easily cut when carrying, by setting a grinding mechanism 8 on one side of the cutting mechanism, Use the grinding mechanism 8 to grind the edge of the cut, so as to avoid the occurrence of the situation where t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com