Multicolor transfer printing type industrial printer

A technology of printers and printing mechanisms, applied in printing devices, printing, metal processing, etc., can solve the problems of inability to flexibly change the printing sequence, difficult control of printing color registration accuracy, and waste of ribbons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

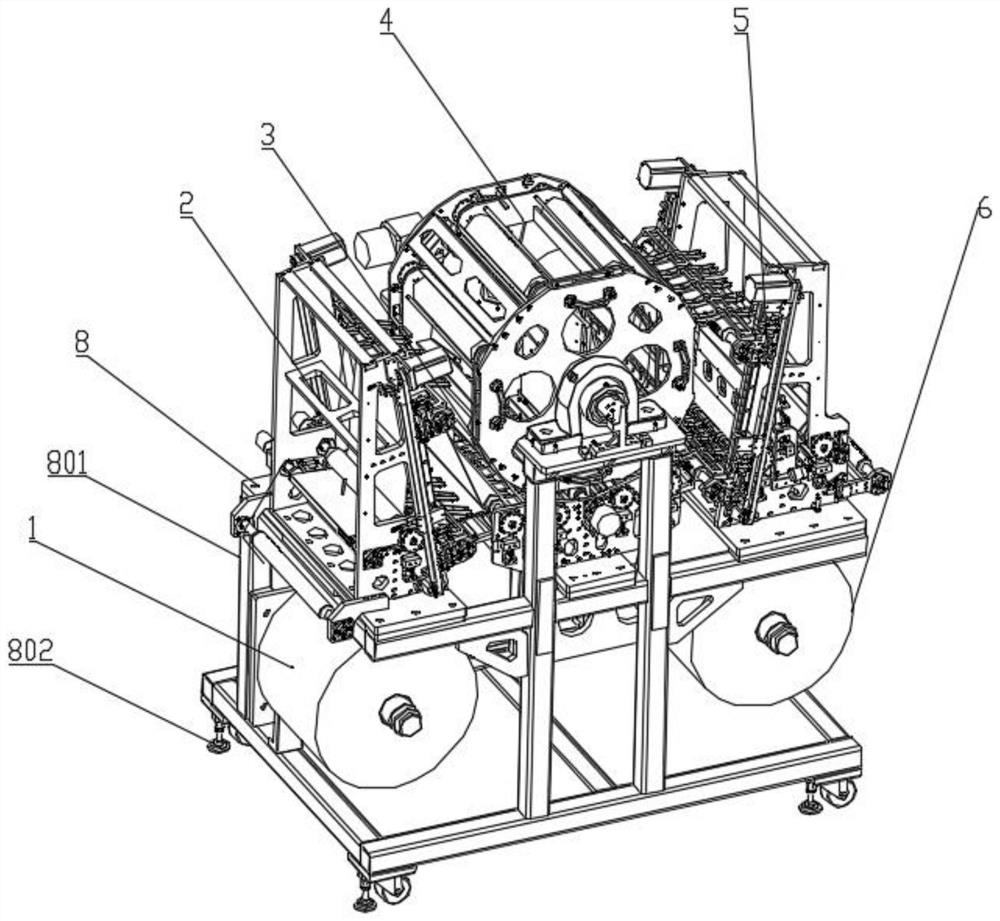

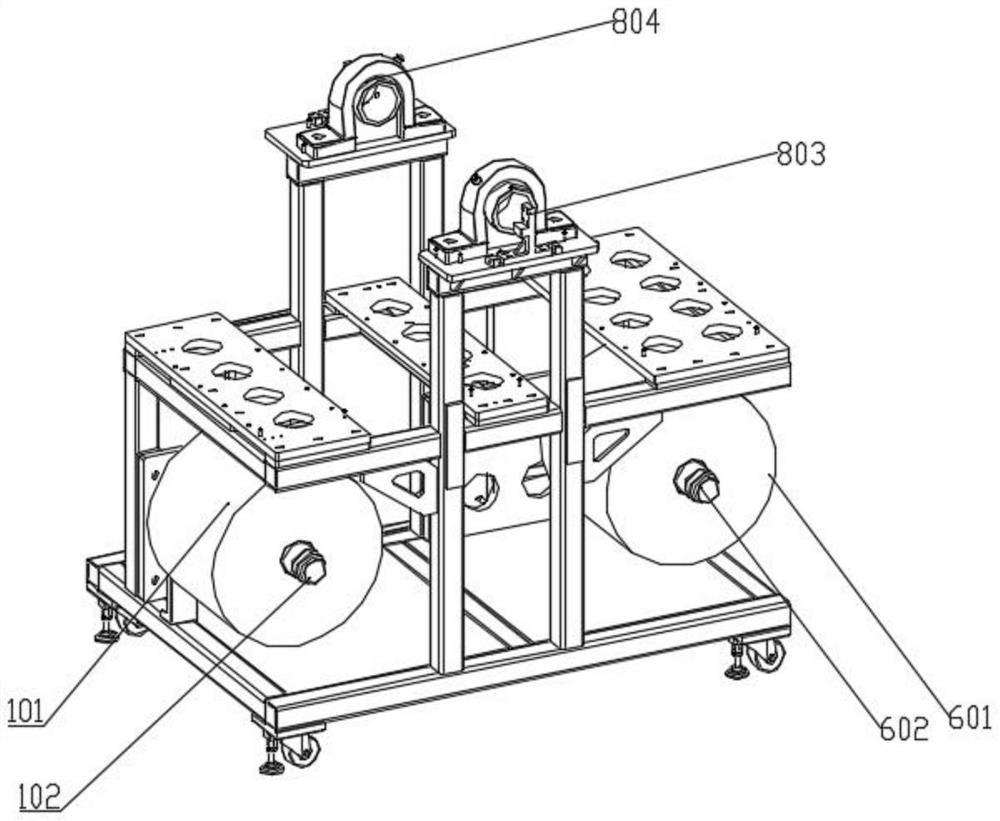

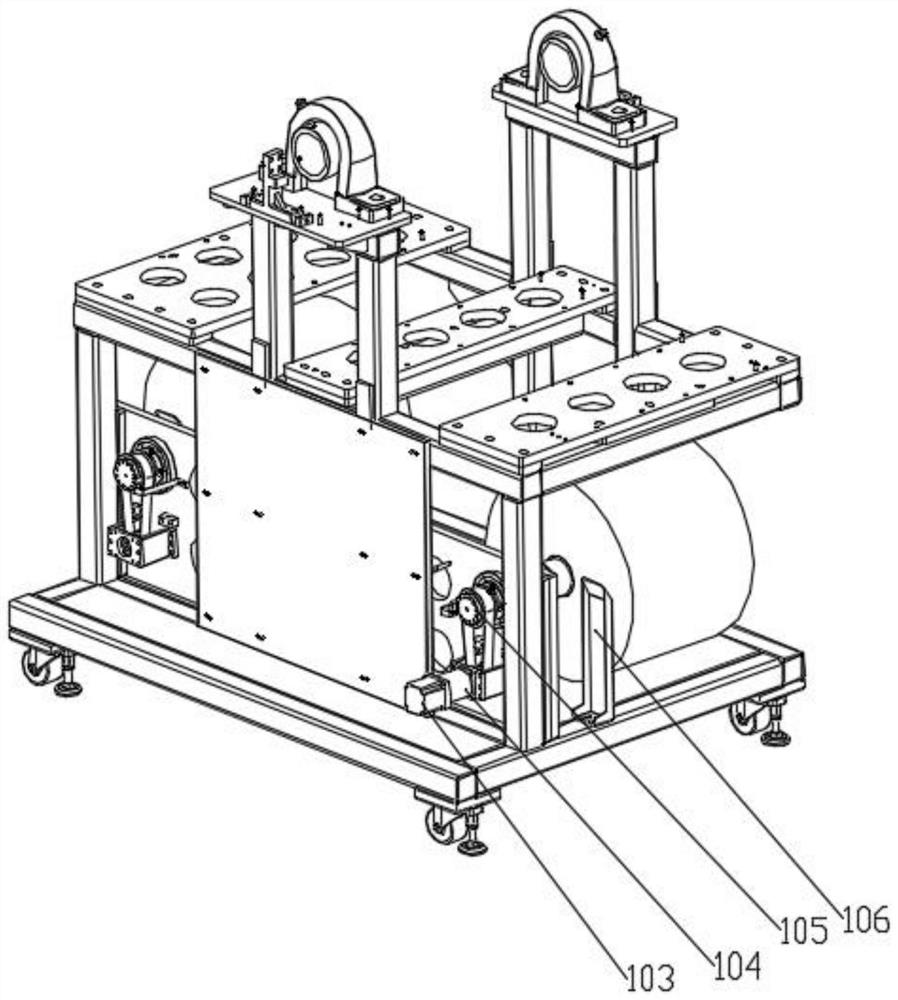

[0040] like Figure 1-4 As shown, this embodiment provides a multi-color transfer printing industrial printer, including: a frame body and a tape feeding mechanism 1 arranged on the frame body 8, a tape front section transmission buffer mechanism 2, and a tape middle section transmission buffer mechanism 3 , tape printing mechanism 4, tape back section transmission buffer mechanism 5 and tape unloading mechanism 6, frame body 8 includes frame 801 and frame 801 bottom connected with foot cup type casters 802.

[0041] Tape feeding mechanism 1, tape front transmission buffer mechanism 2, tape middle transmission buffer mechanism 3, tape printing mechanism 4, tape rear transmission buffer mechanism 5, and tape unloading mechanism 6 are arranged in sequence along the tape feeding direction, and the tape middle transmission buffer A tape printing mechanism 4 is arranged vertically above the mechanism 3. The tape front transmission buffer mechanism 2 receives and temporarily stores ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com