Antique tile waistline arc top anti-cracking transportation equipment

A technology of transportation equipment and waistline, which is applied in the field of anti-crack transportation equipment on the arched top of antique tile waistline, which can solve problems such as damage, achieve the effects of dispersing support force, ensuring safety, and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

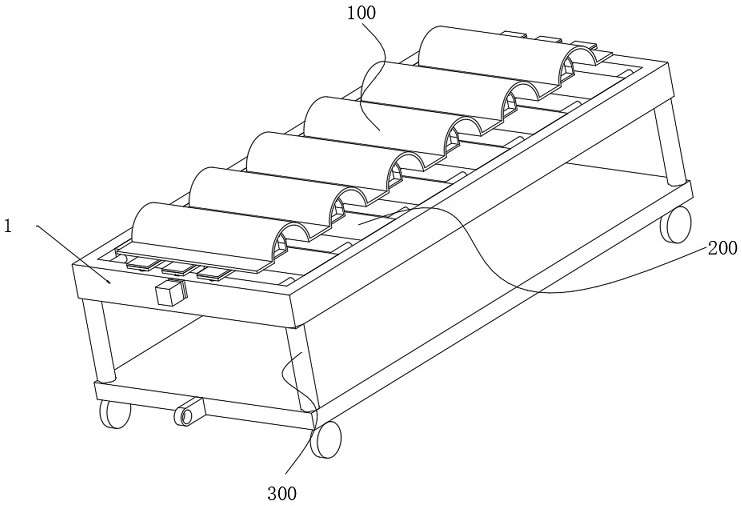

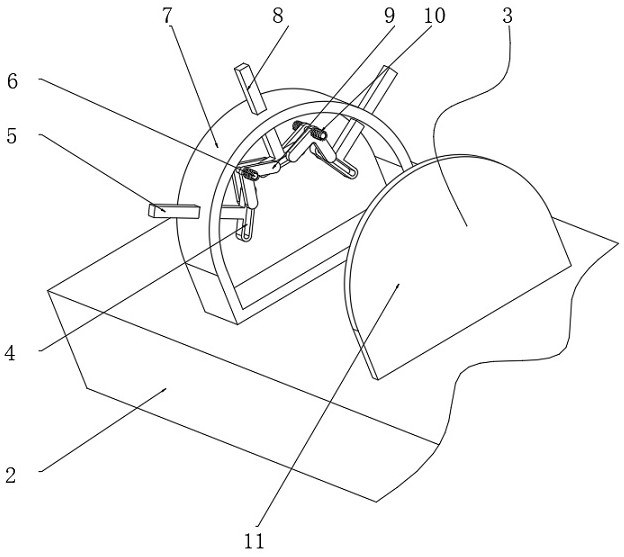

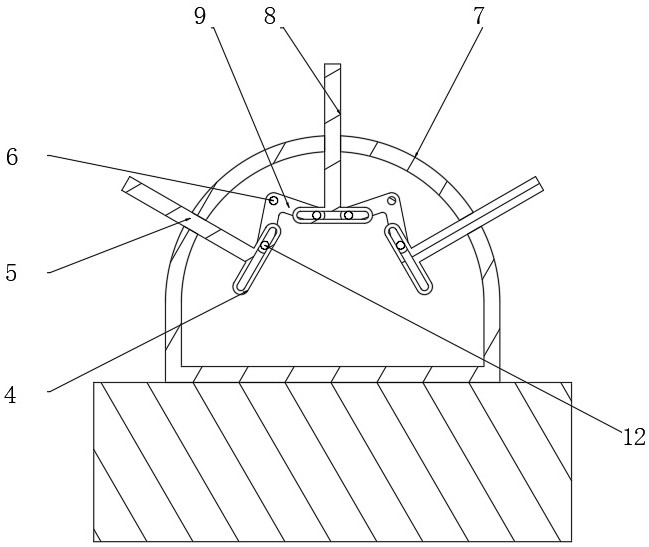

[0036] An anti-crack transportation equipment for antique tile waist line arc top, such as Figure 1-6 As shown, it includes a rectangular frame 1 and multiple sets of support mechanisms 200 arranged inside the rectangular frame 1 for supporting the antique tiles 100 to be transported. The waistline arc support 3 of the outer wall, the waistline arc support 3 includes a shell 7 and an end cover 11 fixed to each other by bolts, and the inner wall of the shell 7 is slidably connected with two symmetrical side support rods 5 and A top support rod 8, the ends of the side support rod 5 and the top support rod 8 are welded with a grooved carriage 4, and the inner wall of the housing 7 is connected with a broken line connecting rod 9 through a rotating shaft 6, and the broken line connecting rod Both ends of 9 are welded with sliding protrusions 12, and sliding protrusions 12 are slidably connected to the inner wall of the grooved carriage 4; when the device is in use, the waistline ...

Embodiment 2

[0042] An anti-crack transportation equipment for antique tile waist line arc top, such as Figure 8 As shown, in order to solve the problem of transportation loss; this embodiment makes the following improvements on the basis of Embodiment 1: the side support rod 5 has the same structure as the top support rod 8, and both include a sliding cylinder body 28 and are fixed to the sliding cylinder by bolts. The cylinder head 29 at the end of the body 28, the inner wall of the sliding cylinder body 28 cooperates to slide a piston 32, the outer wall of the piston 32 is fixed with a piston rod 31 by bolts, and the outer wall of the piston rod 31 is bonded with a hemispherical hollow head 30, In this device, by improving the structure of the side support rod 5 directly in contact with the antique tile, it is set in the form of the piston 32 cooperating with the sliding cylinder 28. Due to the compressibility of the gas, when the cavity of the sliding cylinder 28 is closed, It can pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com