Intelligent gripper for hoisting heavy equipment

A heavy-duty equipment and intelligent technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of inaccurate positioning, unable to meet weight requirements, etc., achieve efficient and accurate gripping and hoisting, strong rigidity, and prevent back and forth swaying Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with drawings and embodiments.

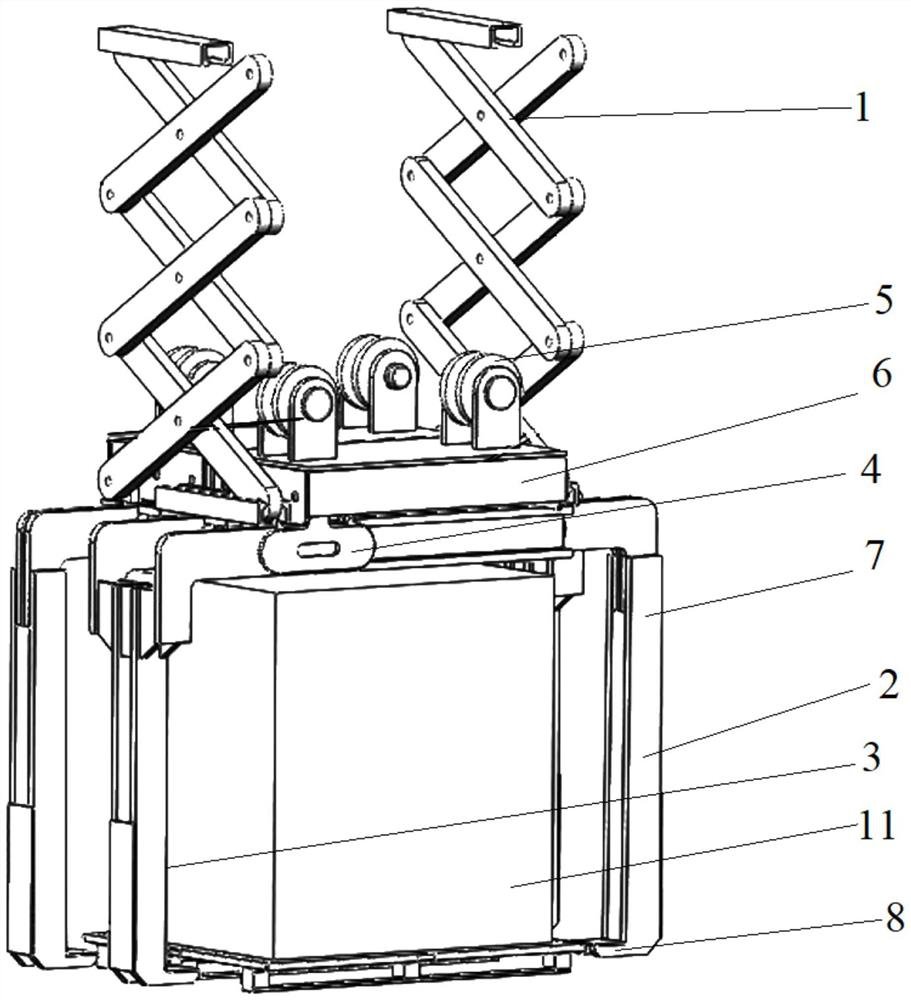

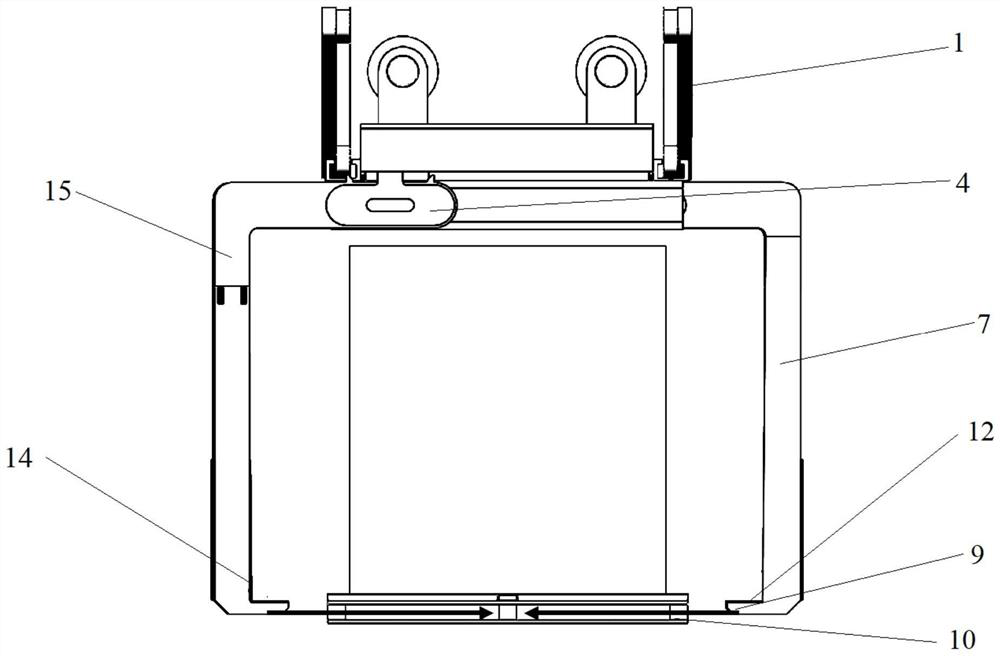

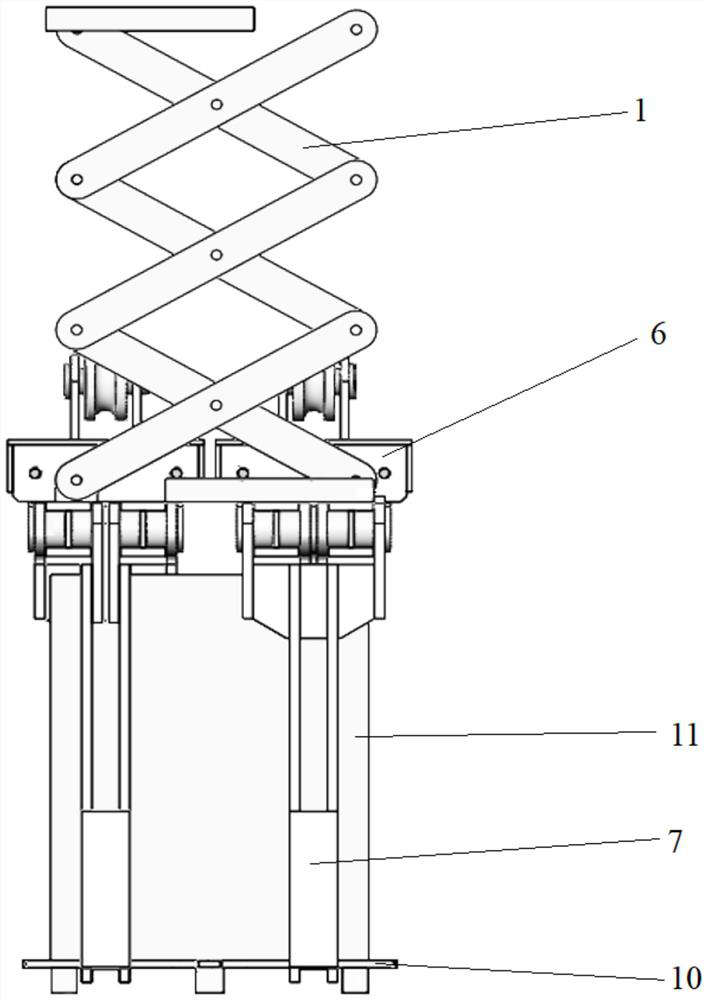

[0016] refer to Figure 1 to Figure 3 , the present embodiment provides a smart gripper for hoisting heavy equipment, including at least a pulley block 5 and a gripper, the smart gripper includes more than two groups of gripper units arranged in parallel, and between adjacent gripper units Connected at the top; the gripper unit is composed of the left jaw 3, the right jaw 2 and the transmission mechanism 6, the pulley block is fixed on the top of the transmission mechanism, the structure of the left jaw is C-shaped, and the right jaw The structure is reverse C-shaped, both of which include a connecting rod 15 located above and arranged horizontally, a vertically arranged pliers leg 7 and a clamp 8 arranged horizontally below, the connecting rod in the left jaw and the connecting rod in the right jaw The connecting rods are nested with each other, and both are connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com