An automatic assembly machine and assembly method for an automobile hub bearing outer ring assembly

A technology for bearing outer rings and automobile hubs, applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of polluted parts, complex structure, low assembly efficiency, etc., achieve efficient and accurate clamping, simple and fast process, and improve The effect of assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

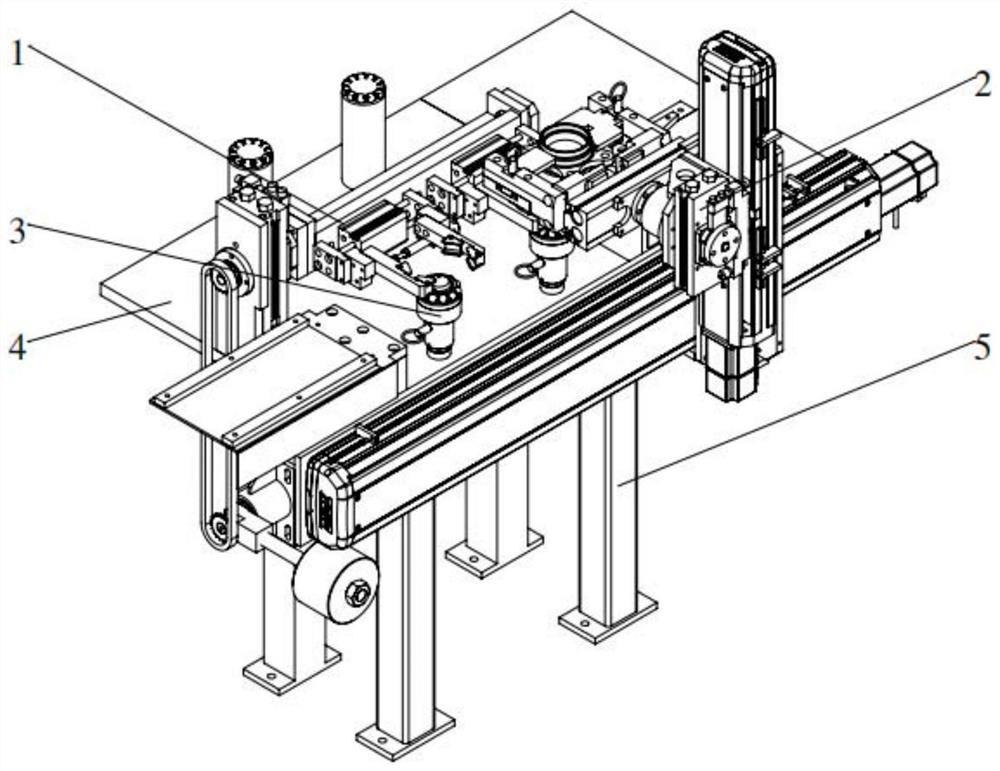

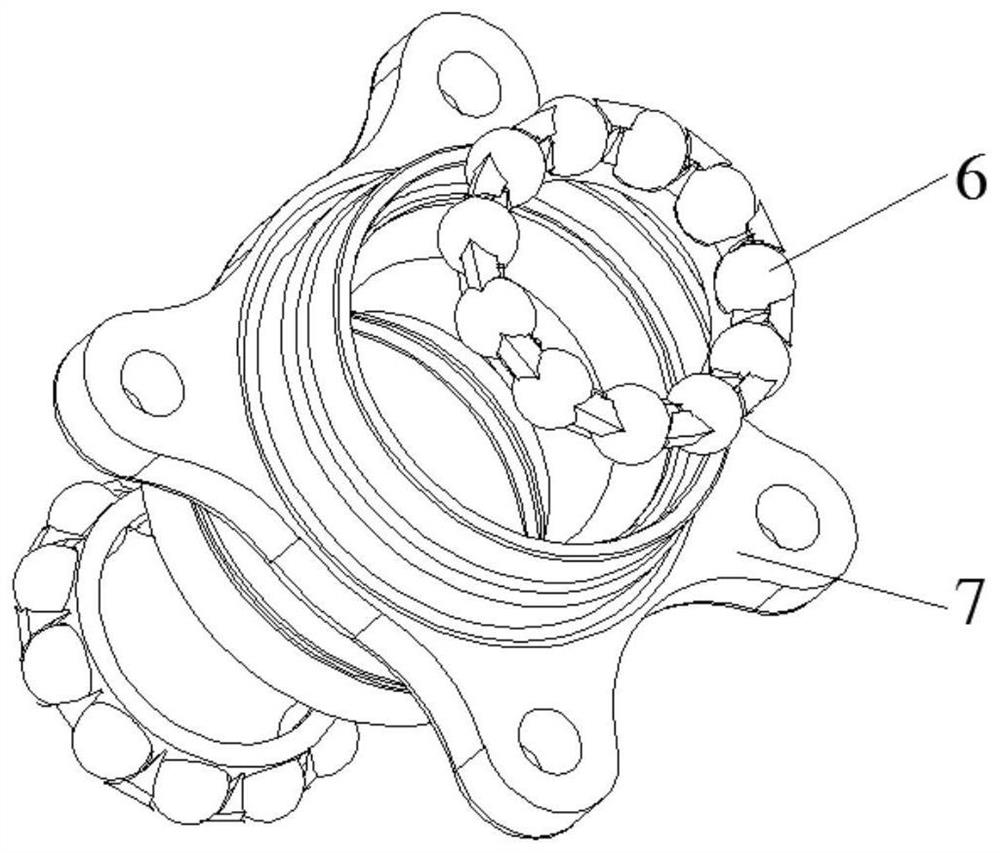

[0075] Such as Figure 1-2 As shown, an automatic assembly machine for an automobile hub bearing outer ring assembly is characterized in that a feeding mechanism 1 connected to a cage 6 loaded with balls, an XZ-axis Cartesian coordinate robot 2, two auxiliary assembly tables 3, and a workbench 4 And the frame 5, the workbench 4 is installed on one side of the frame 5, and the workbench 4 is installed with the feeding mechanism 1 and the auxiliary assembly table 3 of the ball cage 6 from the back to the front, and the hub bearing outer The XZ axis Cartesian coordinate robot 2 connected by circle 7 is installed on the other side of frame 5 .

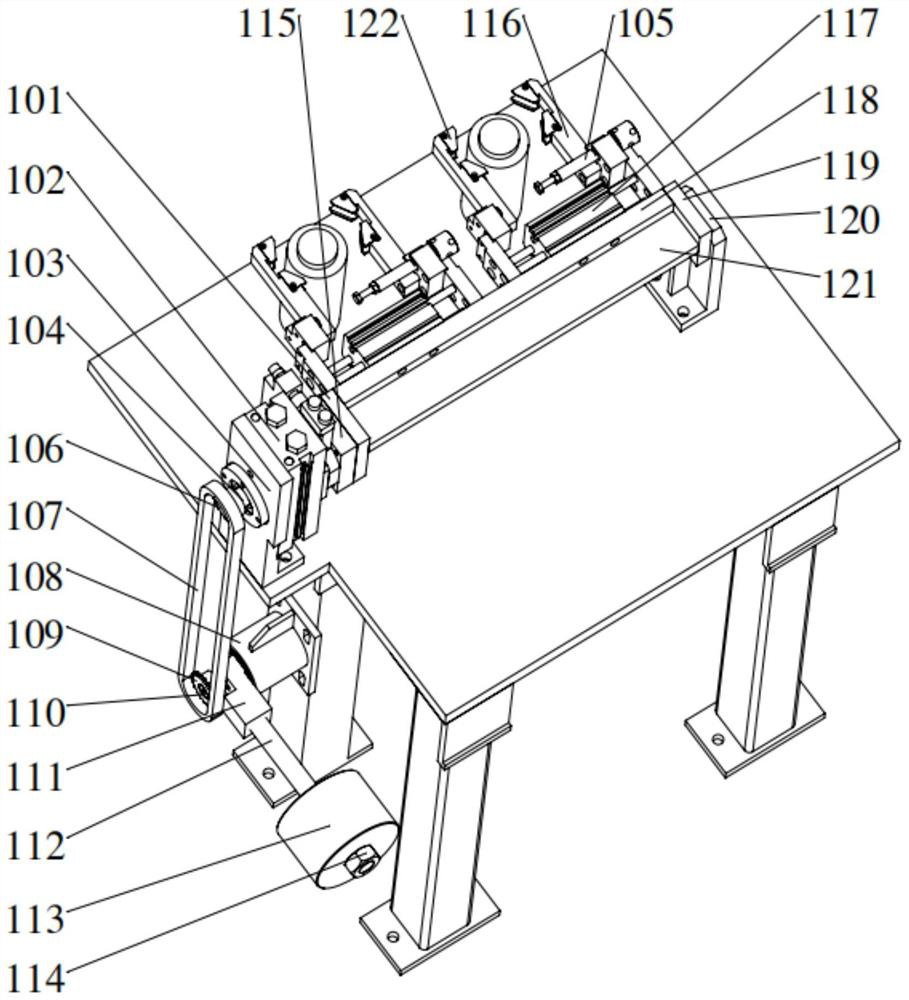

[0076] Feeding mechanism 1 comprises feed turning over cylinder block 103, as image 3 As shown, a bearing I is installed in the center of the feed turning cylinder block 103, and an auxiliary turning shaft 104 is installed on the bearing I. The left end of the auxiliary turning shaft 104 runs through the bearing I and is connected with t...

Embodiment 2

[0081] An assembly method of an automatic assembly machine for an automobile hub bearing outer ring assembly, comprising the following steps:

[0082] The first step: the cage 6 with the balls installed is sent from the previous station to the waiting position for feeding; the two feeding horizontal opening cylinders 117 of the feeding mechanism 1 respectively drive the feeding jaws 116 to carry out clamping movement, clamping Hold the two cages 6 filled with balls.

[0083] Step 2: The flange plate on the feeding turning cylinder 102 is connected to the turning adapter plate 115, and the turning adapter plate 115 is connected to the auxiliary turning shaft 104 through a key, and the rotary motion of the feeding turning cylinder 102 is transmitted to the auxiliary turning shaft 104 ; Auxiliary turning shaft 104 transfers the rotation motion to the feeding turning manipulator of feeding mechanism 1 respectively to realize the turning motion from 0 degree to 180 degrees, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com