Synthetic method of antirust additive for lubricating oil

A technology of anti-rust additive and synthesis method, which is applied in the direction of additives, lubricating compositions, petroleum industry, etc. It can solve problems such as unfavorable production, dark product color, and difficult treatment of acidic wastewater, so as to reduce side reactions and reduce tar-like by-products , the effect of increasing productivity

Pending Publication Date: 2022-03-01

XINXIANG RICHFUL LUBE ADDITIVE CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the current synthesis process, because the excess maleic anhydride in the reaction is prone to side reactions at a temperature of 150°C, a large amount of tar-like by-products are generated, resulting in a dark product color, which cannot be formulated with light-colored lubricating oil, and there are still small coke-like particles , in order to reduce the production of tar-like by-

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

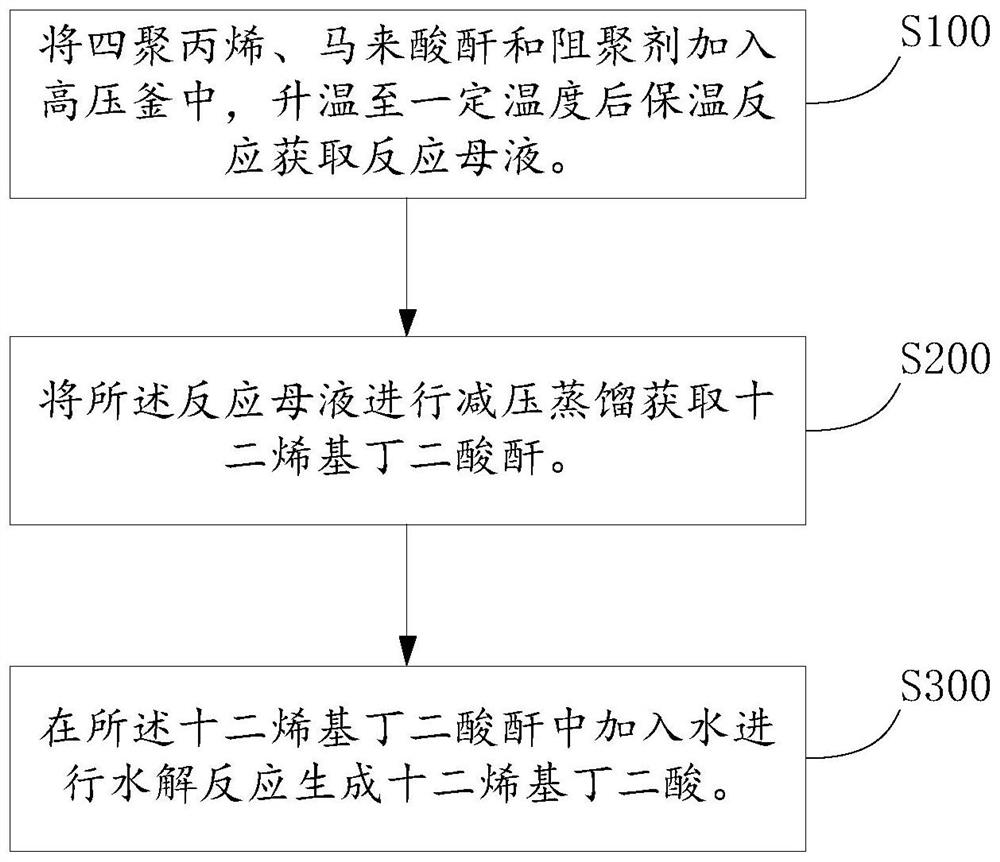

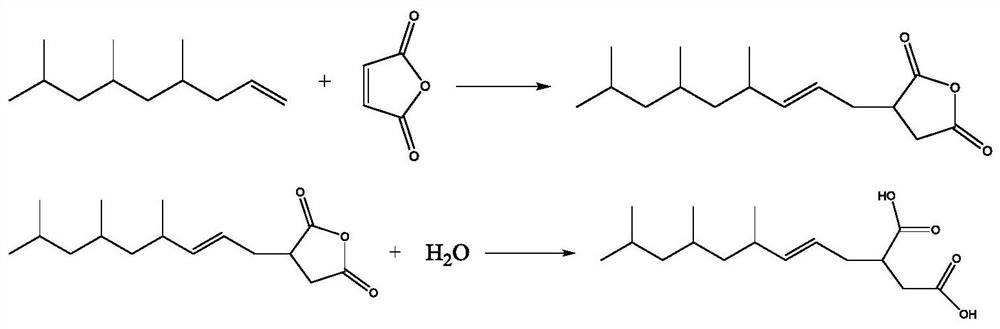

The synthetic method comprises the following steps: S1, adding tetra-polypropylene, maleic anhydride and a polymerization inhibitor into a high-pressure kettle, heating to a certain temperature, and carrying out a heat preservation reaction to obtain a reaction mother solution; s2, carrying out reduced pressure distillation on the reaction mother liquor to obtain dodecenyl succinic anhydride; and S3, adding water into dodecenyl succinic anhydride, and carrying out hydrolysis reaction to generate dodecenyl succinic acid. According to the synthetic method of the lubricating oil antirust agent, the polymerization inhibitor and excessive tetra-polypropylene are added, so that maleic anhydride reacts completely, side reactions are reduced, tar-shaped by-products are reduced, products with light colors are generated, meanwhile, due to the reduction of the side reactions, the yield of dodecenylsuccinic acid is increased, and in addition, the yield of the lubricating oil antirust agent is increased. The maleic anhydride is completely reacted, so that the step of washing is avoided, and no acid wastewater is generated.

Description

technical field [0001] The application relates to the field of lubricating oil additives, in particular to a method for synthesizing lubricating oil antirust additives. Background technique [0002] Dodecenylsuccinic acid is a kind of antirust agent in lubricating oil additives, mainly used in steam turbine oil, also widely used in hydraulic oil, guide rail oil, spindle oil and industrial lubricating oil, for steel, cast iron and copper Alloys have good anti-rust effect. [0003] The current synthesis process of dodecenylsuccinic acid is to react linear or branched dodecene with maleic anhydride, then wash with water to remove incompletely reacted maleic anhydride, and then hydrolyze to obtain dodecenylsuccinic acid. In the current synthesis process, because the excess maleic anhydride in the reaction is prone to side reactions at a temperature of 150°C, a large amount of tar-like by-products are generated, resulting in a dark product color, which cannot be formulated with ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07C51/087C07C57/13C10M129/28C10N30/12

CPCC07C51/087C10M129/28C10M2207/127C10N2030/12C07C57/13

Inventor 刘西林刘亚芳徐坤范金凤

Owner XINXIANG RICHFUL LUBE ADDITIVE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com