Bending type wallboard building material structure and rapid assembly mode thereof

A building material and bending technology, which is applied in the direction of building insulation materials, building material processing, building components, etc., can solve the problems of reduced work efficiency, long cycle time, and large demand for manpower, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

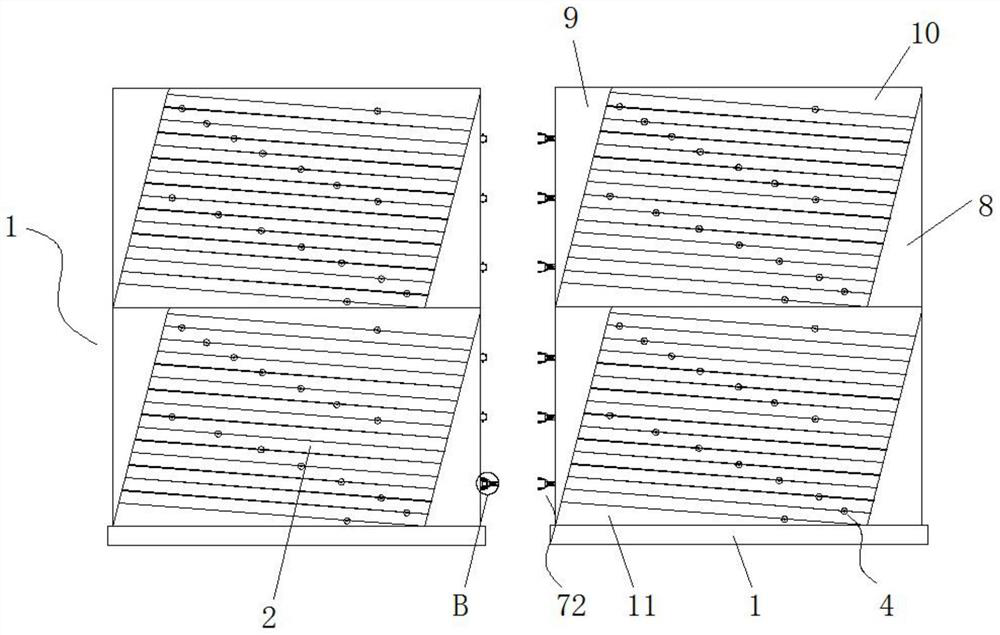

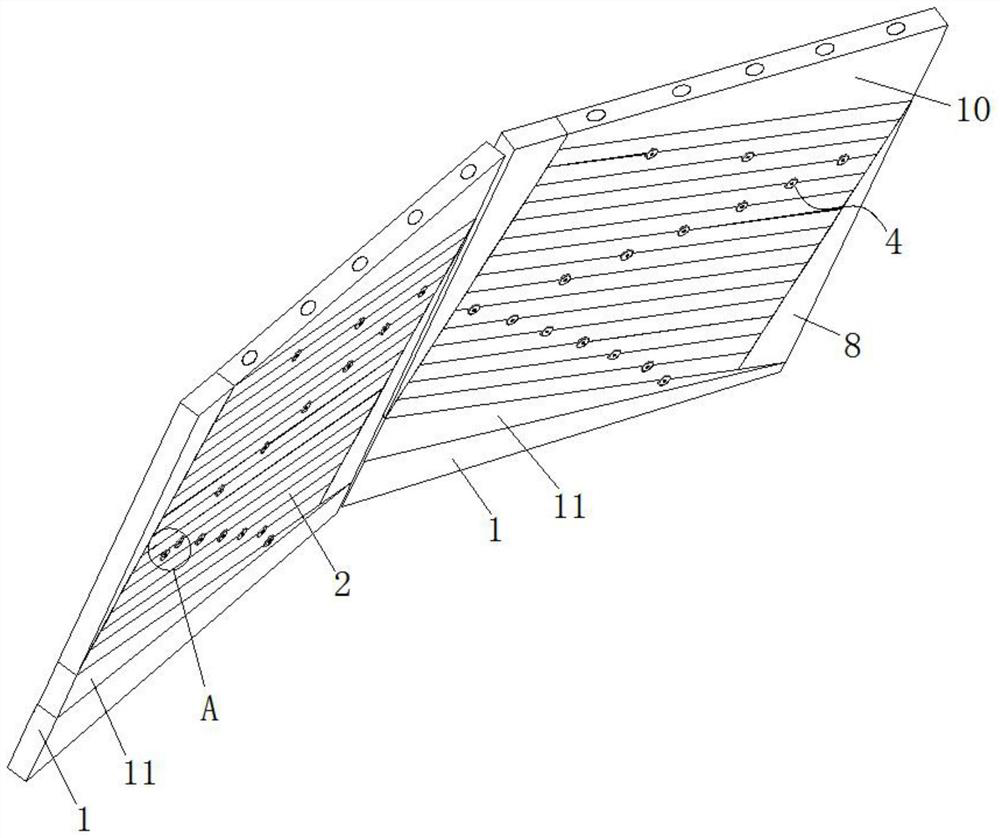

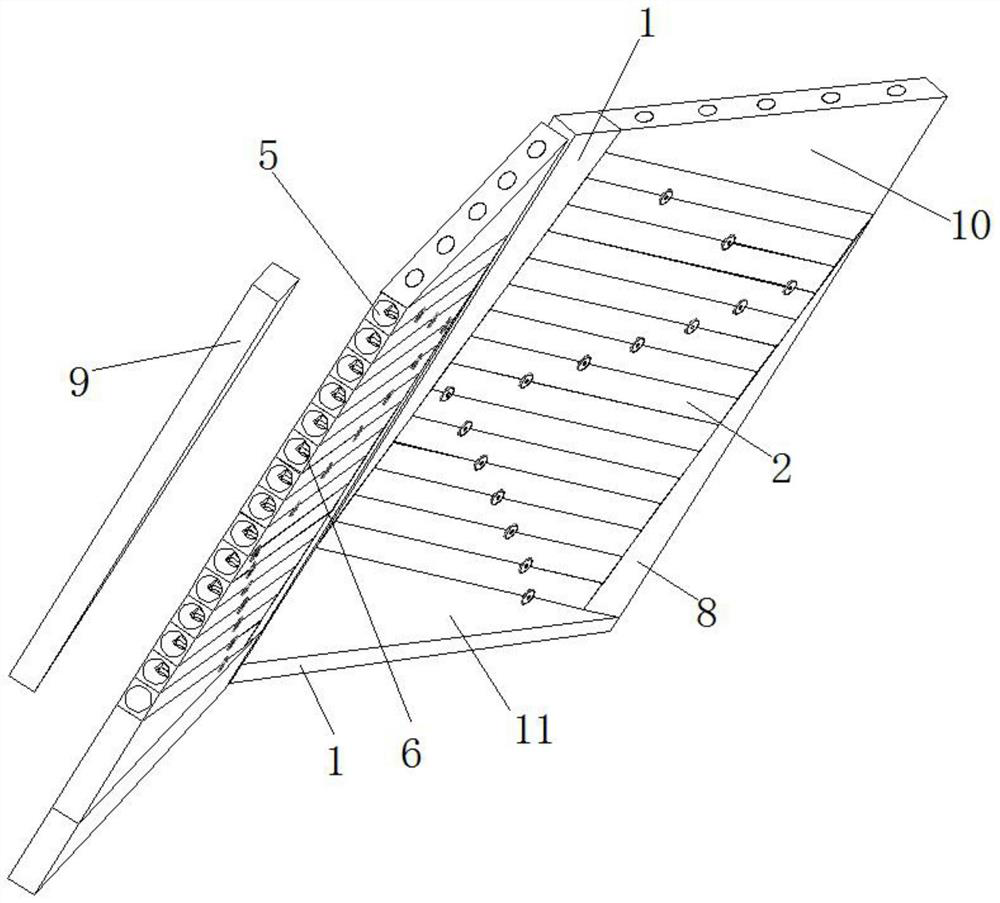

[0027] The present invention will be further elaborated below by means of the accompanying drawings and examples.

[0028] Such as Figure 1-7 Shown: a bent wall panel building material structure and its quick assembly method, including a block 1 at the bottom, a masonry pipe 2 placed on the block 1 obliquely in the vertical direction, and a plurality of pipes arranged on the block 1 A supporting wallboard 3, a plurality of masonry pipes 2 are provided, and the two masonry pipes 2 that are offset up and down are fastened by bolts 4, and the middle part of the masonry pipe 2 is a filling cavity 5 that runs through its two ends. So that pouring cement mortar at the top can realize filling of all masonry pipes 2 cement mortar.

[0029] The filling cavity 5 between the upper and lower masonry pipes 2 communicates with each other through the open groove 6, and the building blocks 1, the masonry pipe 2 and the supporting wall panels 3 together form a building wall 20, and there are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com