Assembled automobile engine split charging tray

An automotive engine, assembly-type technology, applied in positioning devices, metal processing mechanical parts, clamping and other directions, can solve the problems of not being able to maximize production efficiency and assembly accuracy, and not be able to meet multi-model collinear production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

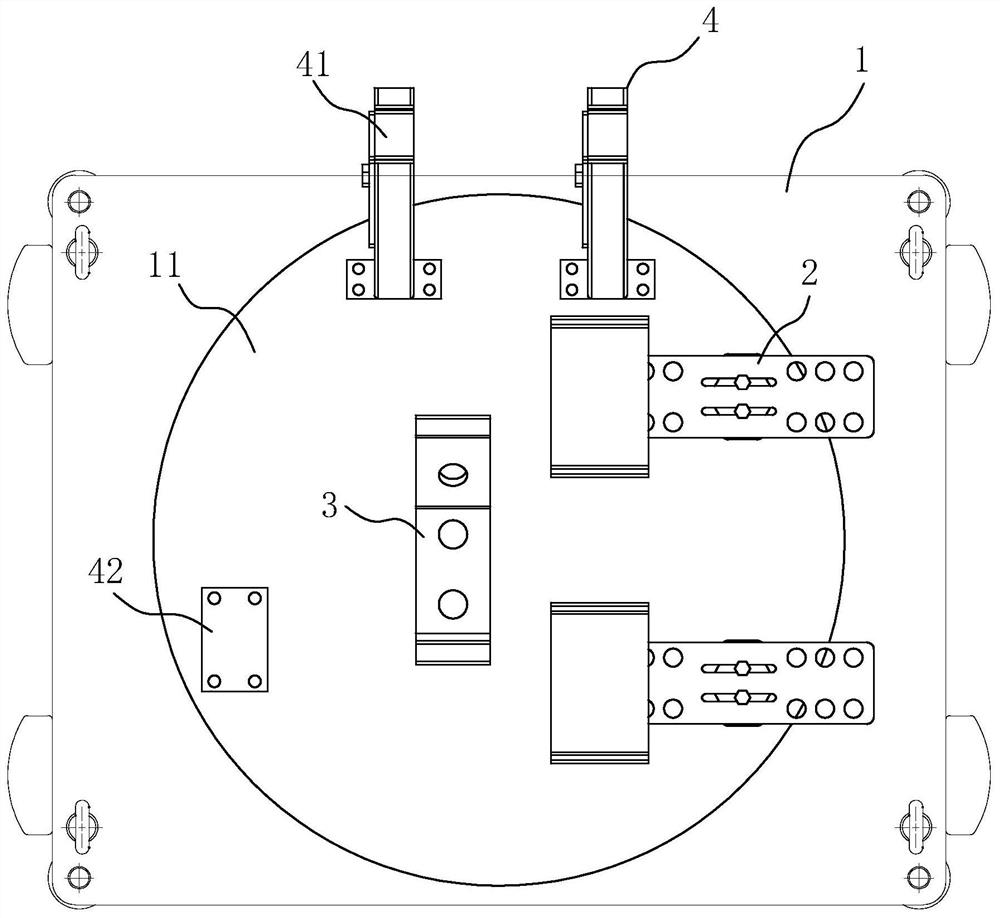

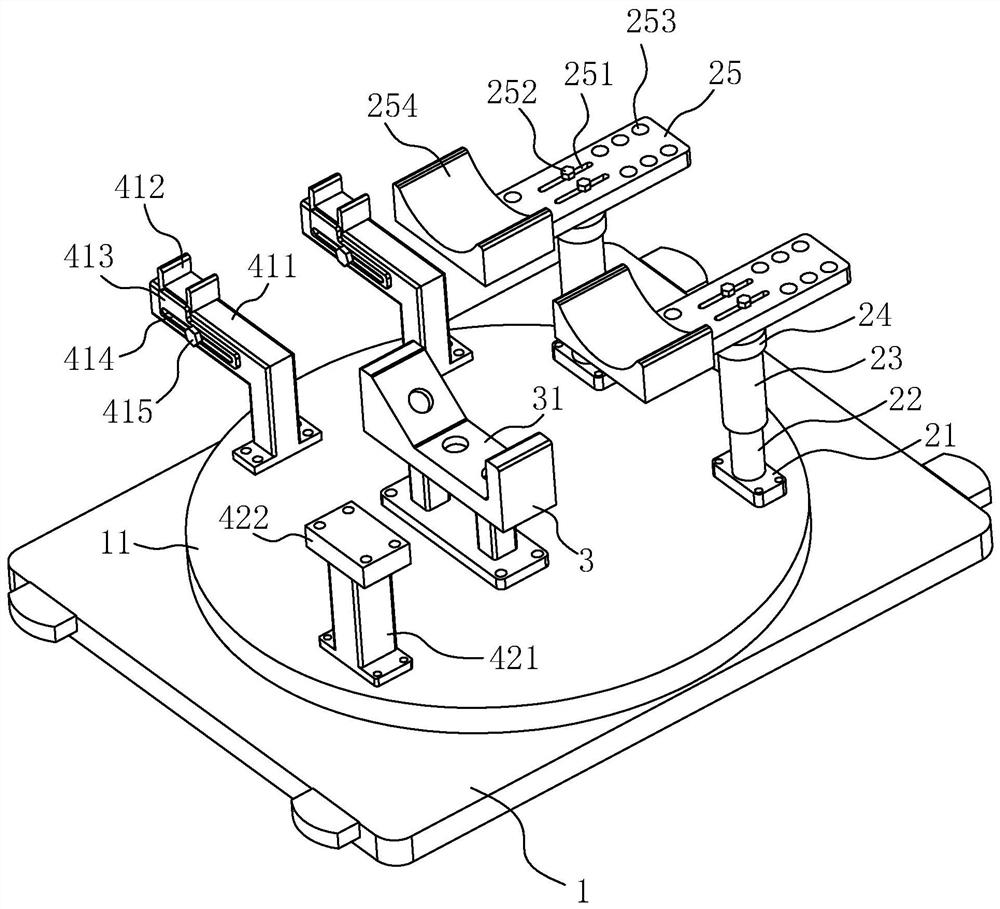

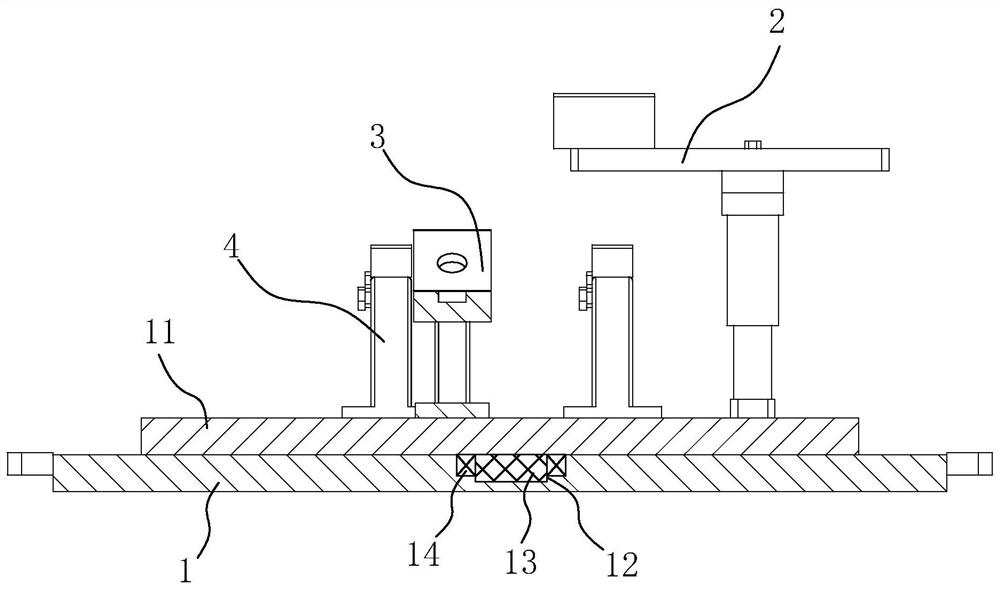

[0031] An assembled automobile engine sub-package tray, such as Figure 1 to Figure 4 As shown, it includes: a mounting base plate 1, on which a supporting plate 11 is rotatably connected; a number of engine support assemblies 2 arranged on the supporting plate 11; a transmission supporting block 3 detachably connected to the supporting plate 11, and a transmission support The block 3 is provided with a limit slot 31 corresponding to the transmission; and a subframe support assembly 4 detachably connected to the carrying tray.

[0032] Specifically, a mounting groove 12 is provided on the mounting base 1, and a stabilizing bearing 14 is embedded in the mounting groove 12, and the bearing plate 11 is rotationally connected with the mounting base 1 through a support shaft 13 embedded in the stabilizing bearing 14, so that the bearing plate The plate 11 and the installation base plate 1 can achieve a stable rotational connection, so as to facilitate the assembly process in all di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com