Erosion-resistant normally-open type inner blowout prevention valve

A normally open, internal blowout prevention technology, applied in wellbore/well valve devices, wellbore/well components, buildings, etc., can solve problems such as reducing the degree of erosion of the sealing surface, damage to the sealing surface, etc. Achieve the effect of eliminating direct erosion, prolonging service life and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

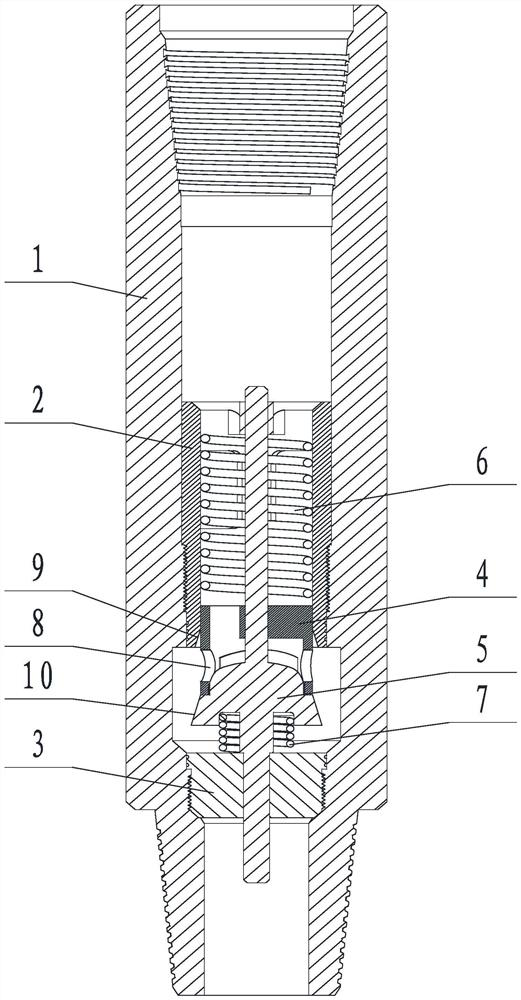

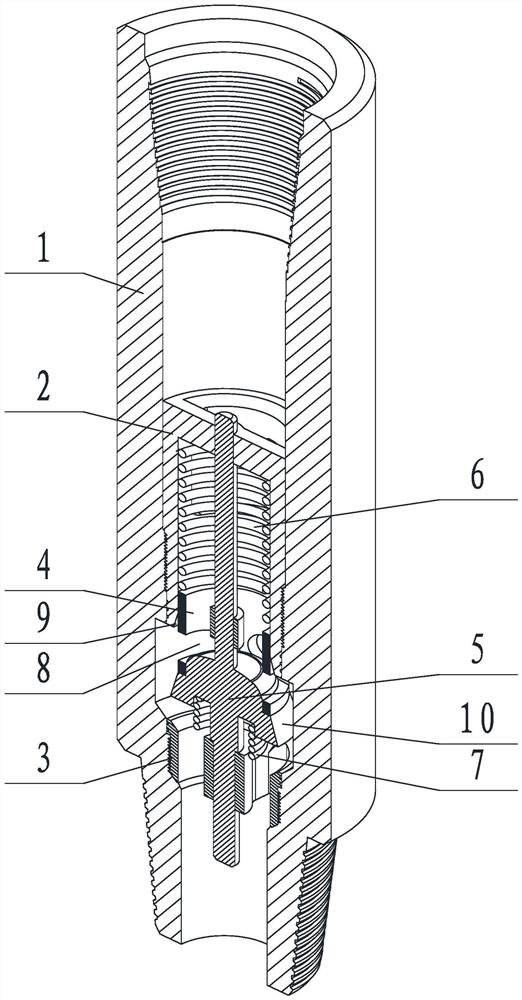

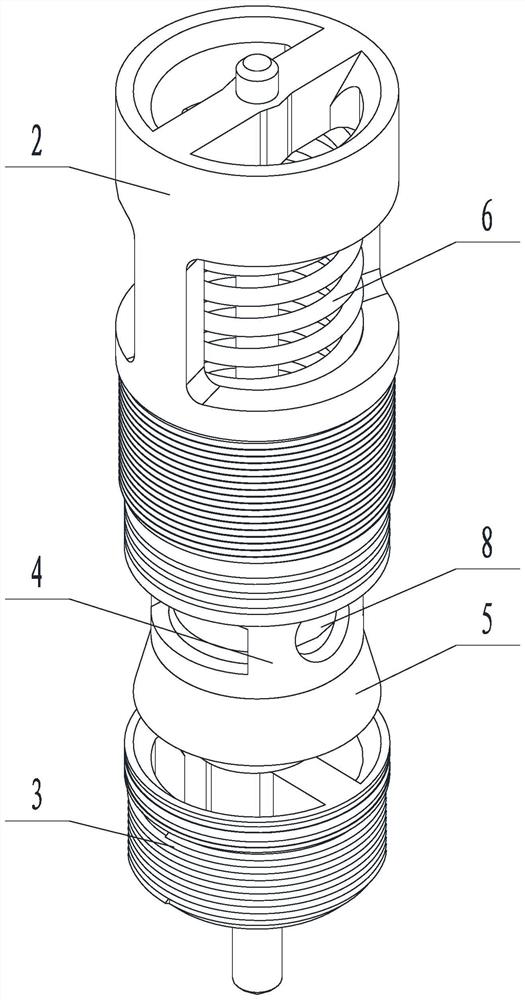

[0066] Such as Figure 1 to 4 A normally open internal anti-spray valve shown, including a valve body 1, and a hover 2 fixed to the valve body 1, the lower valve seat 3, sliding in the upper valve seat 2 The sleeve 4 is fixed to the spool 5 below the slider 4, and the upper valve seat 2 is provided inside the lower valve seat 3 with an overflow channel, and the top of the top of the slider 4 is provided between the top surface of the upper side of the upper valve seat. A second elastic member 7 is disposed between the bottom of the spool 5 and the top of the lower valve seat 3, and a plurality of discharge passages 8 are opened in the sidewall of the slider 4, and the bottom portion of the upper portion of the upper seat 2 is provided with a first sealing surface 9, and the spool 5 is provided. The second sealing surface 10 that matches the first sealing surface 9, and the second sealing surface 10 is located below the discharge passage 8; the first sealing surface 9, the second se...

Embodiment 2

[0071] A normally open internal anti-spray valve, on the basis of Example 1, the spool 5 Figure 6 to 8 As shown, the convex portion 501, a connecting portion 502, and sealing portion 503 are included from the top and downward distribution.

[0072] The surface of the projection 501 is disposed to extend from the upper and downwardly extending surfaces;

[0073] The connecting portion 502 is used to securely connect with the slide 4;

[0074] The outer side surface of the sealing portion 503 is a second sealing surface 10.

[0075] Wherein, the outer thread 504 is provided with the outer thread 504, and the top surface of the sealing portion 503 is formed between the bottom surface of the connecting portion 502; the wall thickness of the slide 4 is less than or equal to the width of the annular step 505.

[0076] Such as Figure 9 and Figure 10 As shown, the inner wall of the slide 4 is provided with the first internal thread 506 that matches the first outer thread 504, and the firs...

Embodiment 3

[0080] A normally open internal anti-spray valve, based on any of the above embodiments,

[0081] Poard seat 2 Figure 11 and Figure 12 As shown, the top surface is arranged from the top-downwardly inclined first guide inclinement 201, and the upper side surface of the upper seat 2 is sequentially set up and downward, the second outer thread 203, the first sealing ring assembly Slot 204; the inner wall of the valve body 1 is provided with the second internal thread 101 that matches the second outer thread 203.

[0082] The lower valve seat 3 is Figure 13 As shown, on the top of the second guide bevel 301 inclined inwardly inwardly, the outer side surface of the lower valve seat 3 is sequentially set up, and the third outer thread 303; valve body 1 The inner wall is set to the third internal thread 102 that matches the third external thread 303.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com