Actuating mechanism for measuring exhaust temperature field of turbofan engine with small bypass ratio

A turbofan engine, exhaust temperature technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as blockage, small bypass ratio turbofan engine exhaust temperature field circumferential unevenness, etc., to achieve horizontal Small cross-sectional area, guaranteed efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose, technical solution and advantages of the application more clear, the technical solution in the embodiment of the application will be described in more detail below in conjunction with the drawings in the embodiment of the application.

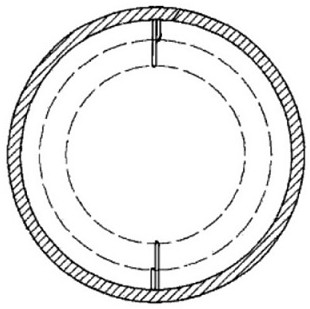

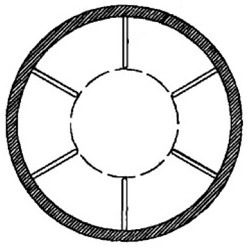

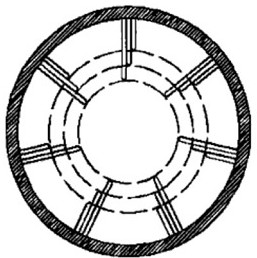

[0032] An actuator for measuring the exhaust temperature field of a turbofan engine with a small bypass ratio is installed on the engine. The engine is provided with a central cone coaxially arranged with the center line of the engine. The outer side of the central cone is used for the discharge of high-temperature exhaust gas. The circumferential outside of the central cone forms a flow field.

[0033] By setting the power device, one or a small number of measuring devices at several measuring points can be driven to rotate along the direction of the centerline of the engine, so that the temperature at various positions in the flow field can be effectively measured to form a temperature field without conside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com