Nested combined sealing device for rotary kiln riding wheel bearing

A combined sealing and nesting technology, which is applied in the direction of drum furnace, furnace, lighting and heating equipment, etc., can solve the problems of bearing wheel shaft seal wear failure, direct economic loss, and lubricating oil corrosion, so as to improve the sealing effect, Effects of reducing economic loss and preventing oil seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

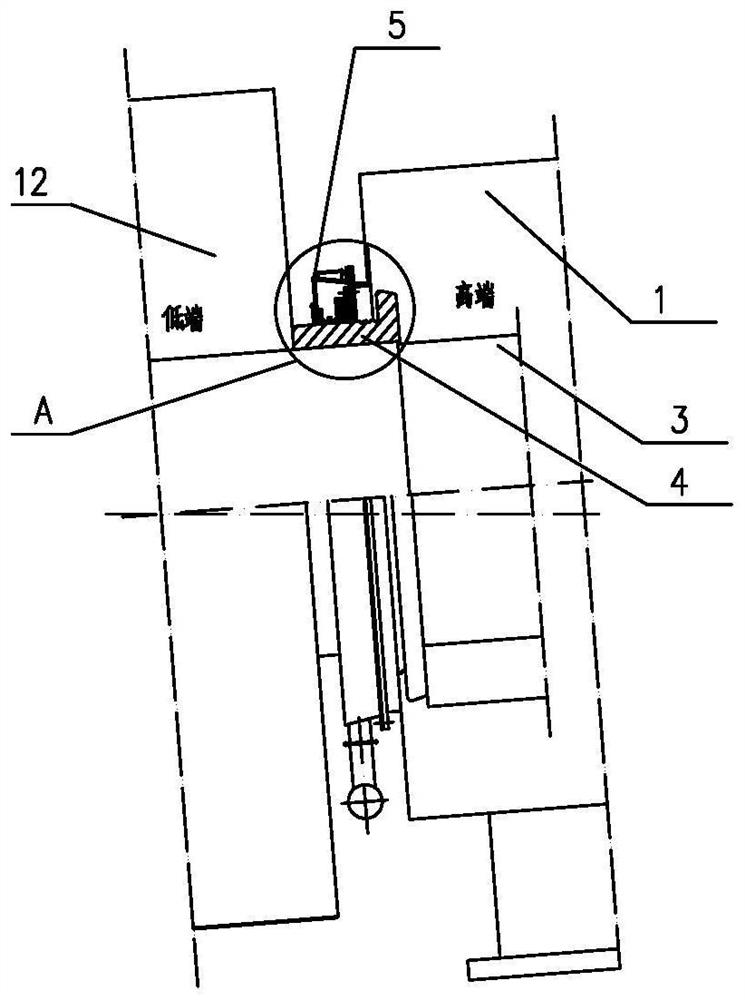

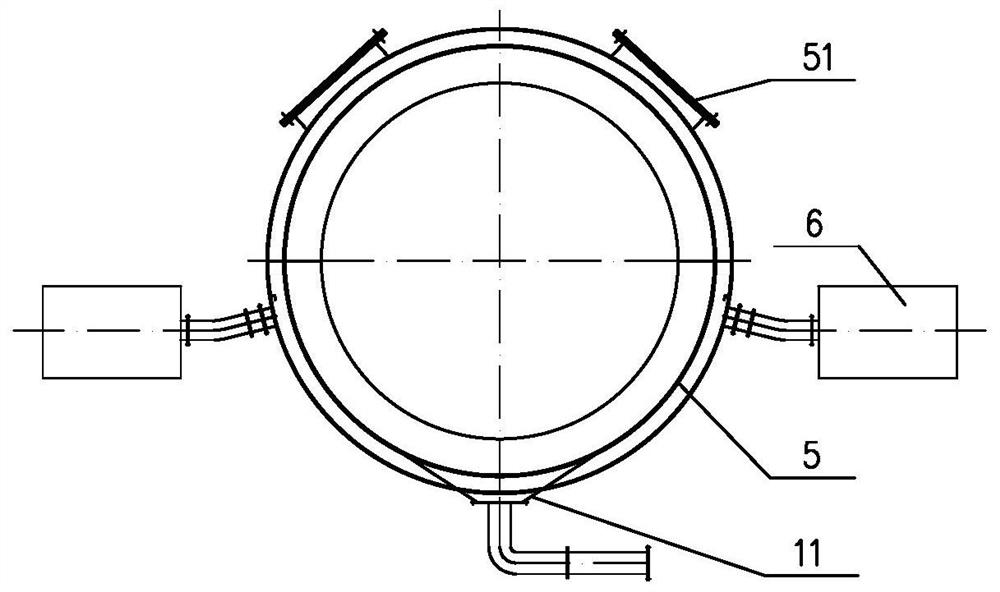

[0020] See Figure 1-Figure 3 As shown, the present invention relates to a nested combined sealing device for a rotary kiln supporting wheel bearing, including a supporting wheel bearing 1, a bearing end cover 2, a supporting wheel shaft 3, a shaft sleeve 4, a protective cover 5, a fan 6, and a V-shaped Sealing ring 7, gap adjustment backing plate 8, double-lip kiln sealing ring 9, protective cover end cover 10 and lower cone bucket 11, the bushing 4 is set on the supporting wheel shaft 3, and extends into the supporting wheel through the opening of the supporting wheel bearing 1 inside the wheel bearing 1; the bearing end cover 2 is provided with a double-lip sealing ring 9, which is set on the shaft sleeve 4 and fixedly connected with the end face of the supporting wheel bearing 1 to seal the opening of the supporting wheel bearing 1 to form the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com