Multi-split temperature controller

A thermostat and front control panel technology, applied in temperature control, instrumentation, non-electric variable control, etc., can solve the problems of inconvenient manipulation, small number of detections, high design cost, etc., and achieve convenient observation, convenient drainage, and convenient control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

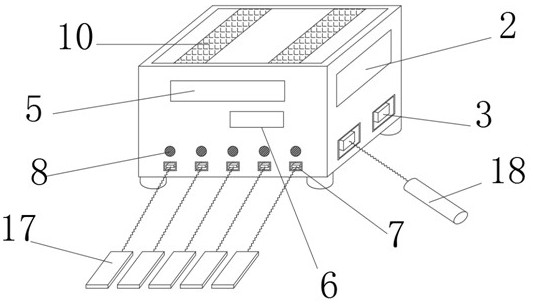

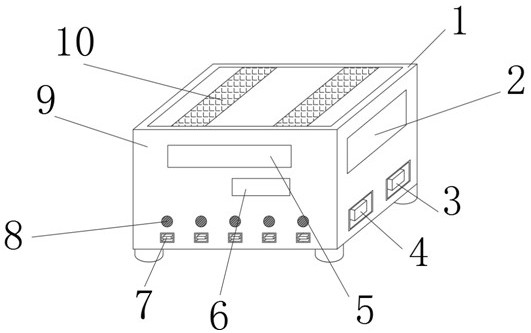

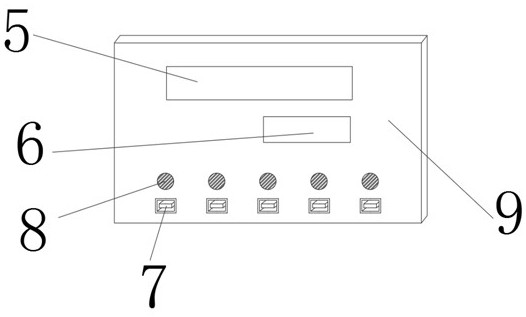

[0022] see figure 1 , 2 , a one-to-many thermostat, including a housing 1, the top of the housing 1 is fixed with a cooling plate 10 by screws on the left and right sides, the front of the housing 1 is fixed with a front control board 9 by screws, and a power display is arranged on the front of the front control board 9 Board 5, the right side below the power display board 5 is provided with a working status board 6, and the bottom of the front control board 9 is evenly provided with five heating connection holes 7, and the heating connection holes 7 are connected with a heating plate 17, and above the heating connection holes 7 are provided with Work indicator light 8 is arranged, and power display board 5, work state board 6, work indicator light 8 and heating connection hole 7 are all fixed on the front control panel 9 by embedding.

[0023] Specifically, the shell 1 is used to protect the internal components to facilitate the protection of the internal components, the hea...

Embodiment 2

[0025] see figure 1 , 3 , 4. A one-to-many thermostat, including a casing 1, a temperature display board 2 is embedded and fixed on the upper right side of the casing 1, a power hole 3 is provided on the right side below the temperature display board 2, and a power hole 3 is provided on the front side of the power hole 3. There is a temperature sensing hole 4, the temperature sensing hole 4 is connected with a temperature detector 18, the power supply hole 3 and the temperature sensing hole 4 are fixed on the shell 1 by embedding, and the inner bottom right side of the shell 1 is provided with a heat sink 15, The left side of the heat sink 15 is provided with a current and voltage detection chip 14, the left side of the current and voltage detection chip 14 is provided with a signal transmission column 13, the inner bottom of the shell 1 is provided with a partition 16 in the middle, and the front side of the partition 16 is provided with a control chip 11. A voltage stabiliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com