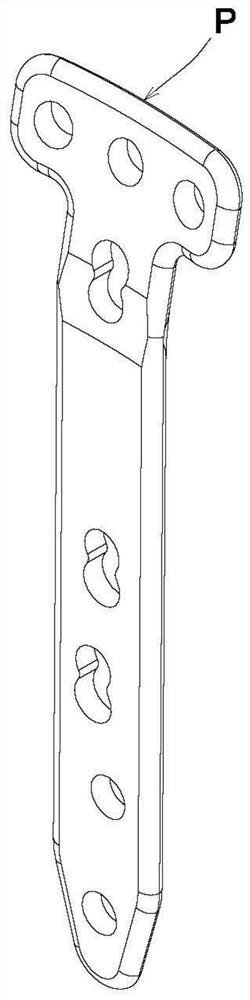

Stable fixing bone plate for high tibia osteotomy

A surgical and stable technology, applied in the field of stable fixed bone plates, can solve the problems of inability to effectively improve the bearing strength of screws, failure of high tibial osteotomy, and stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

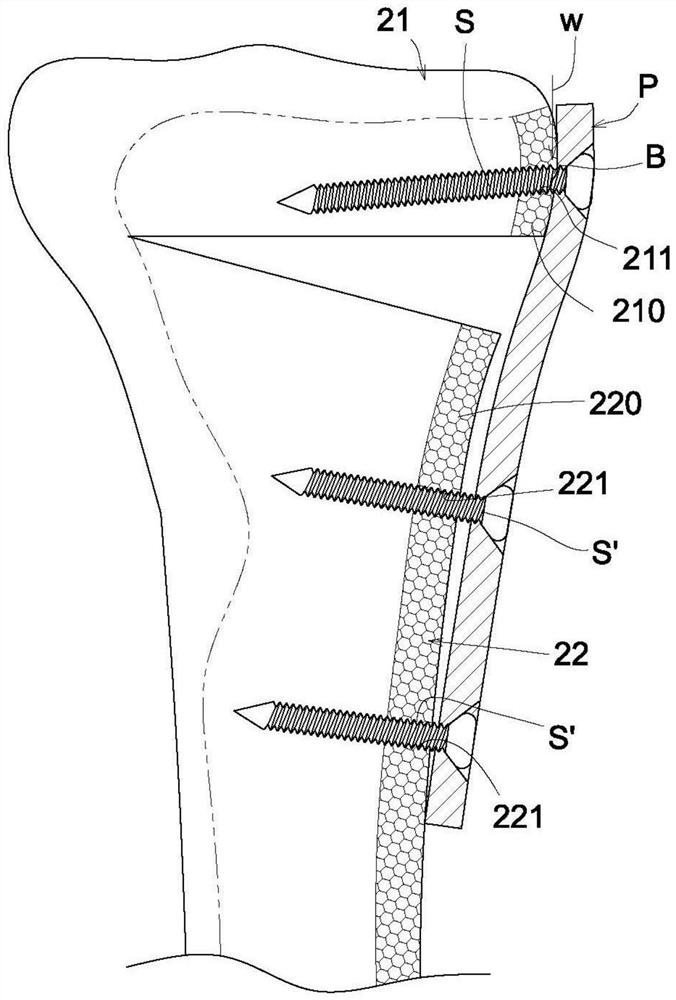

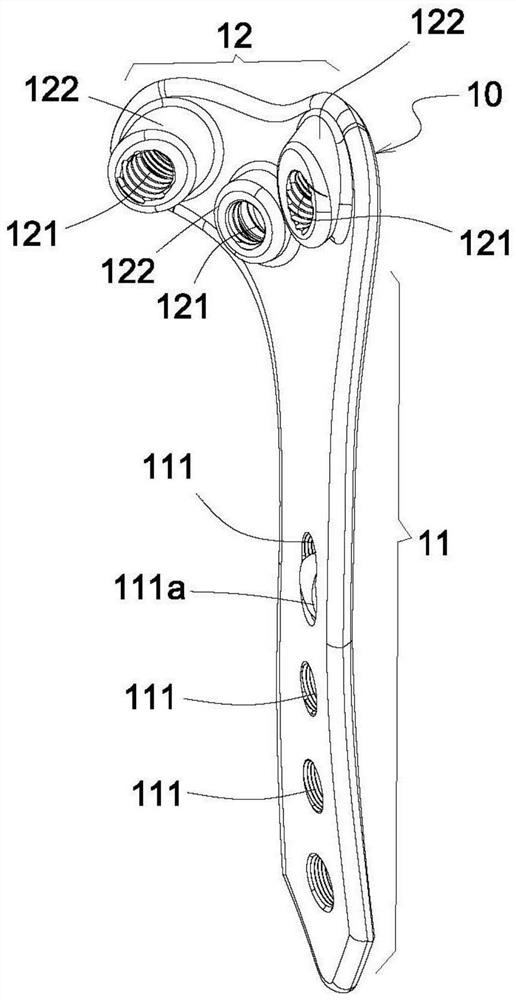

[0033] see Figures 3 to 7 As shown, the present invention relates to a stable fixed bone plate 10 for high tibial osteotomy, including: a longitudinal plate portion 11 and a transverse plate portion 12 arranged transversely from the top end of the longitudinal plate portion 11, wherein The vertical plate portion 11 and the horizontal plate portion 12 are perforated with a plurality of fixing holes 111, 121, and at the rear side of at least one fixing hole 121 of the horizontal plate portion 12, a stud 122 is extended, and the stud 122 The fixing hole 121 penetrates through it. If so, when the present invention is applied, the stud 122 is inserted into the preset hole 23 of the cut upper tibia 21, and then the screw 30 is passed through the fixing hole 121 and locked into the upper tibia 21....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com