Device for carrying out gas-liquid separation by utilizing magnetic screen, working method and spacecraft

A technology of gas-liquid separation and screen, which is applied in the field of space vehicles, can solve the problems of low cost and failure to provide, and achieve the effects of no additional energy consumption, convenient operation, and good air and liquid discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

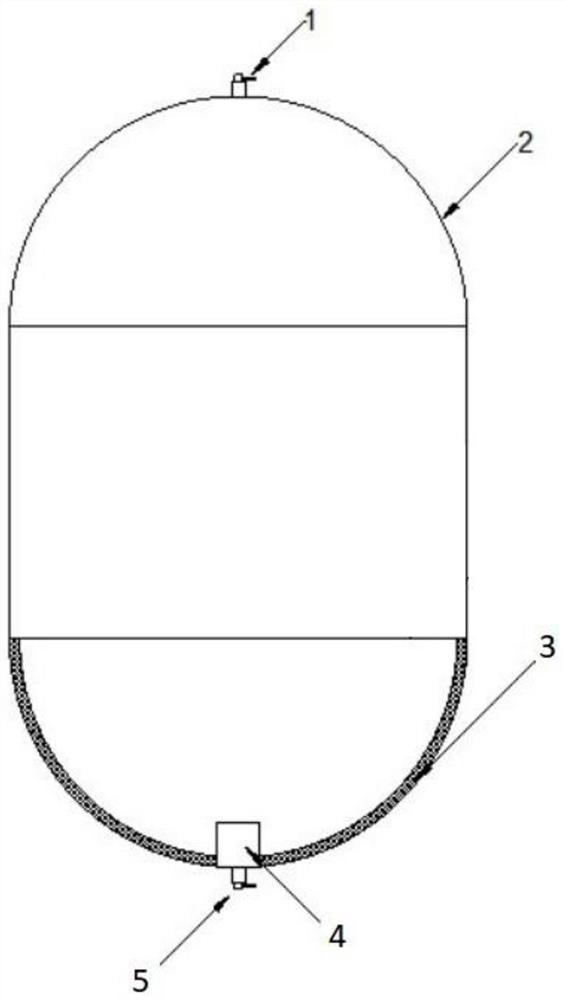

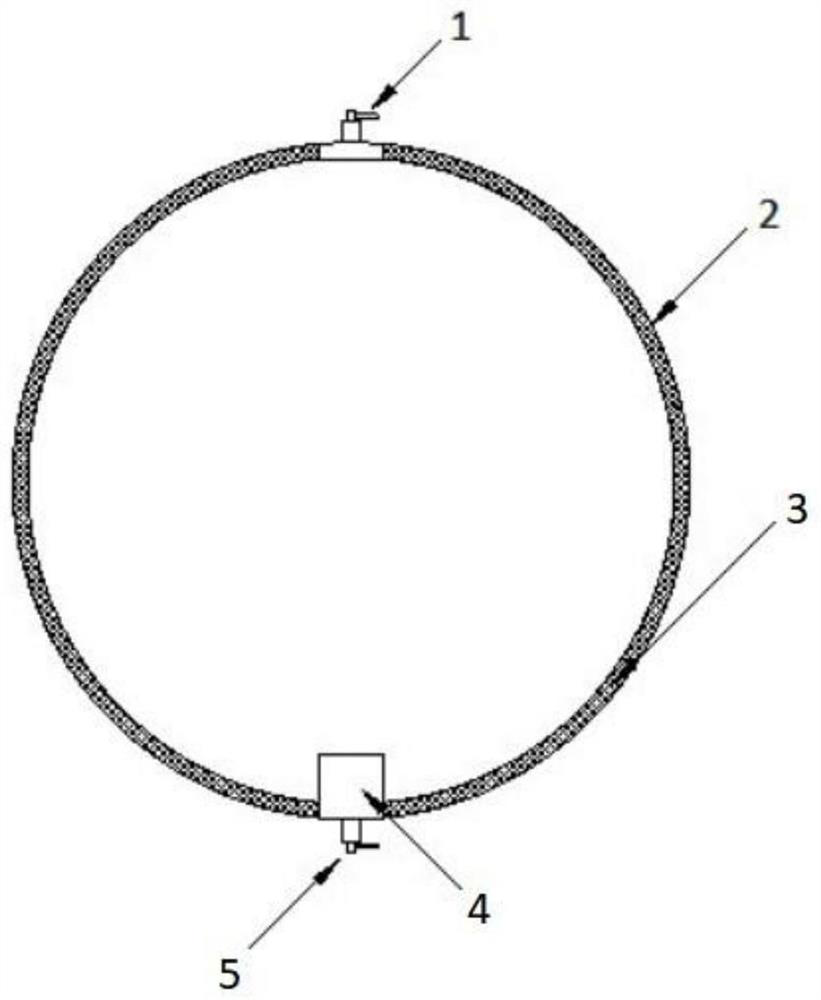

[0051] Such as figure 1 , figure 2 and Figure 4 As shown, a device for gas-liquid separation using a magnetic screen can be used in a space vehicle, including: a housing 2 and a channel 3 with a screen; a channel 3 with a screen and a gas-liquid mixed fluid are installed in the housing 2, and the gas-liquid The mixed fluid includes liquid and gas, and the channel 3 with the screen forms a gradient magnetic field, and the gas-liquid mixed fluid flows to the channel 3 with the screen through the gradient magnetic field, and the liquid without entraining gas is separated through the channel 3 with the screen. An inlet 1 is installed on the top of the housing 2 , an outlet 5 is installed on the bottom of the housing 2 , the outlet 5 is connected to the collector 4 , and the collector 4 is connected to the channel 32 .

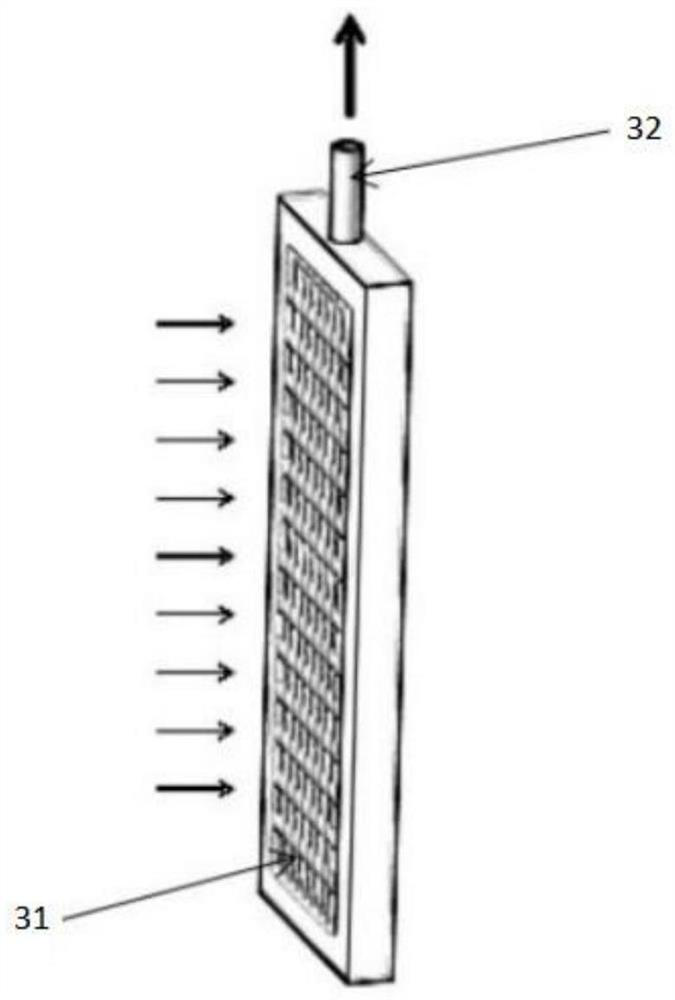

[0052] Such as image 3 As shown, a channel 32 is set inside the channel 3 with a screen, and a screen 31 is installed outside the channel 32. The screen 31 for...

Embodiment 2

[0056] Embodiment 2 is a preferred example of Embodiment 1.

[0057] Such as Figure 1 to Figure 4 As shown, a device for gas-liquid separation using a magnetic screen. The gas-liquid mixed fluid is separated through the screen 31. Under certain conditions, the liquid without gas can pass through the screen 31 smoothly, and the gas cannot break through the surface of the screen 31 to form The liquid film, the screen 31 is made of magnetic material or can generate a stable magnetic field after being magnetized, the magnetic induction intensity of the magnetic field decays from the surface of the screen 31 to both sides away from the screen, thus showing as a gradient magnetic field pointing to the surface of the screen 31 .

[0058] More specifically, if liquid oxygen is a strong paramagnetic fluid, oxygen molecules in a magnetic field will experience a magnetizing force pointing to the direction of increasing magnetic field strength. When the gas-liquid mixed fluid is in the...

Embodiment 3

[0062] Channel 3 with screen can be installed in a semi-management mode or a full-management mode.

[0063] exist figure 1 The channel 3 with a screen mesh adopts a semi-management installation method: the upper end of the shell 2 is the inlet 1, and the lower end is the outlet 5. Channel 3 with screen is installed in the lower half of housing 2 and connected to collector 4 , which is connected to outlet 5 . The gas-liquid mixed fluid enters the lower part of the housing 2 from the inlet 1 and finally fills the channel 3 with a screen. The gas-liquid mixed fluid passes through the channel 3 with a screen for gas-liquid separation, and the liquid without entrainment gathers in the collector 4 and flows from the outlet 5 discharge.

[0064] exist figure 2 The channel 3 with a screen mesh adopts a full-management installation method: the upper end of the shell 2 is the inlet 1, and the lower end is the outlet 5. A channel 3 with a screen is installed on the inner wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com