High-precision multi-plunger row pipetting device

A liquid pipetting device and multi-plunger technology, which is applied in measuring tubes/pipettes, chemical instruments and methods, laboratory utensils, etc., can solve problems such as the influence of suction and discharge accuracy, to ensure accuracy, reduce assembly difficulty, and improve Effect of Seal Reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific working processes are provided, but the protection scope of the present invention is not limited to the following Described embodiment.

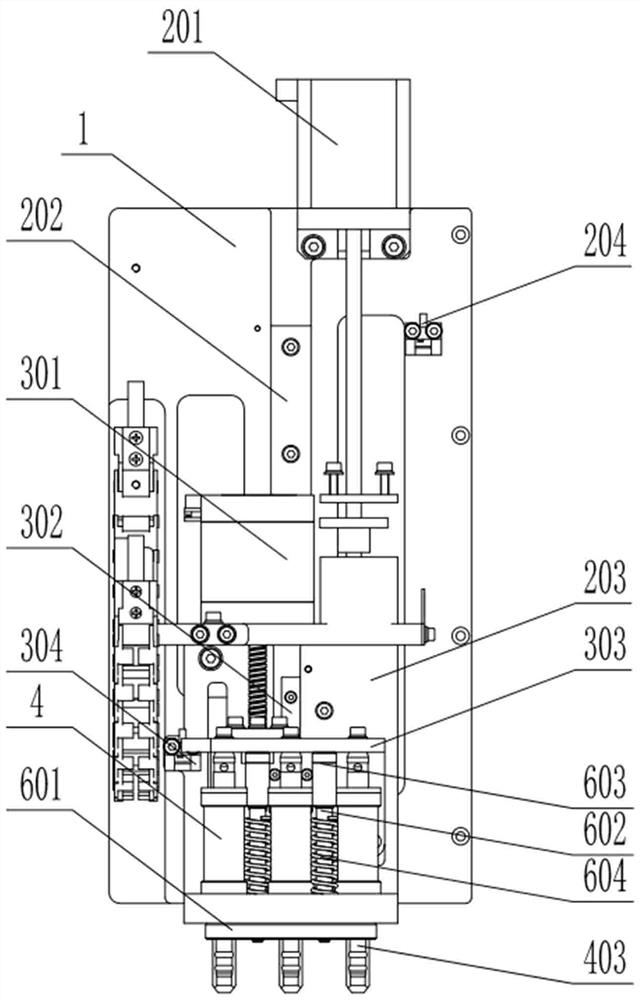

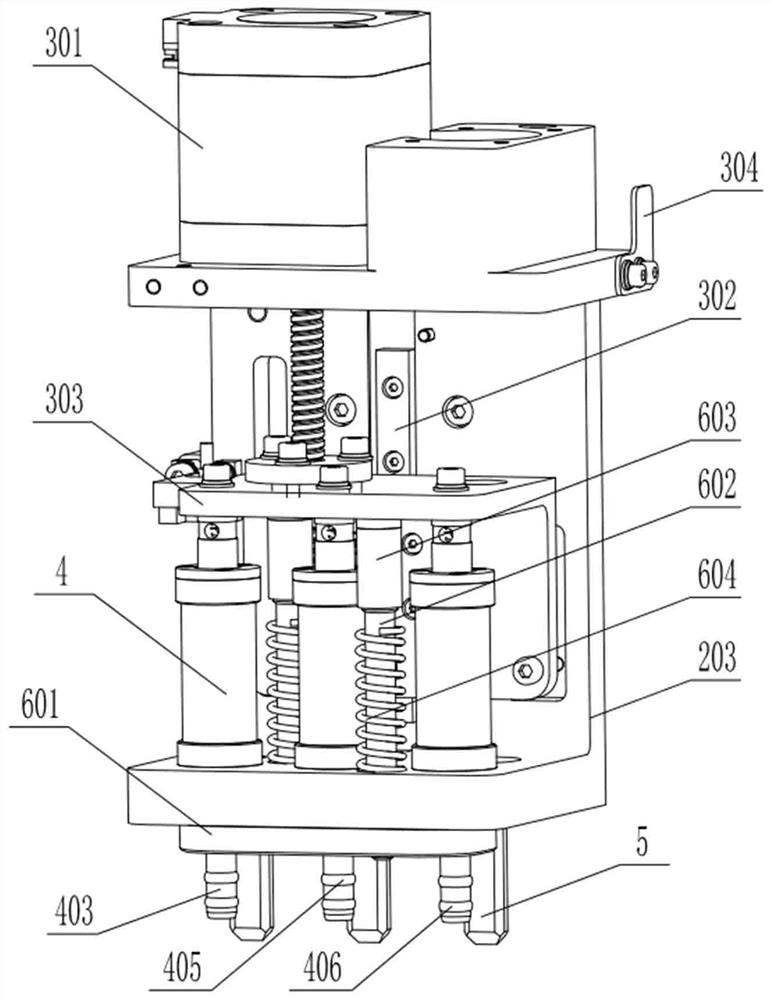

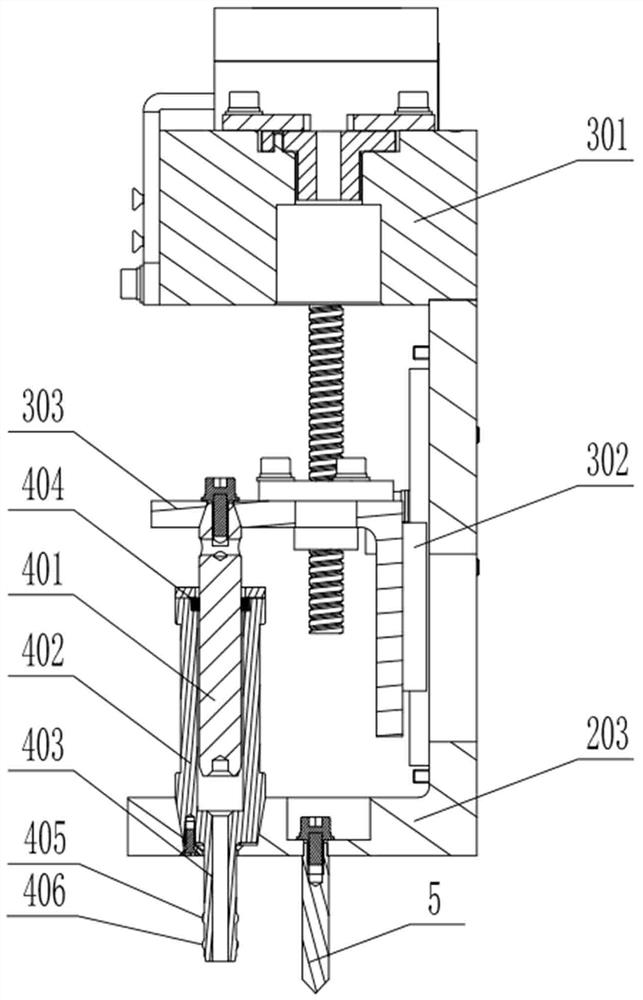

[0030] Such as Figure 1-4 As shown, the high-precision multi-plunger serial liquid pipetting device described in the present invention includes a support 1, and a first lifting mechanism is installed on the support 1, which consists of a first screw motor 201, a first guide rail 202 and a U-shaped structure. The first lifting mounting frame 203 constitutes, wherein, the first screw motor 201 has a first screw rod and a first lifting nut, the first screw and the first guide rail 202 are parallel to each other, the first lifting nut and the first lifting mounting frame 203 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com