Automatic paper folding filter element assembling machine

An automatic assembly machine and assembly mechanism technology, applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of low assembly accuracy, high labor cost, and high labor intensity, and achieve high assembly accuracy, low labor cost, The effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

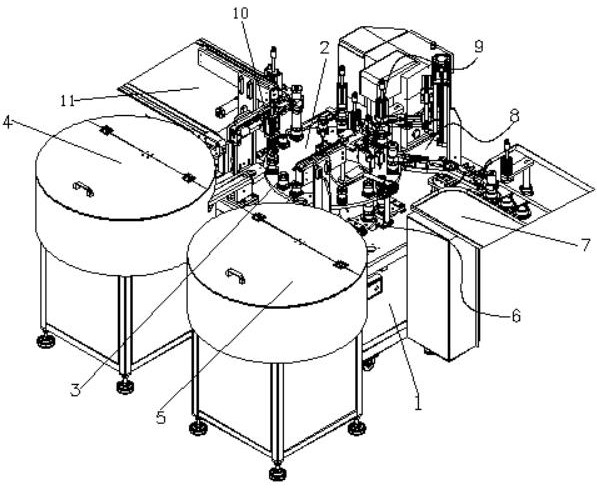

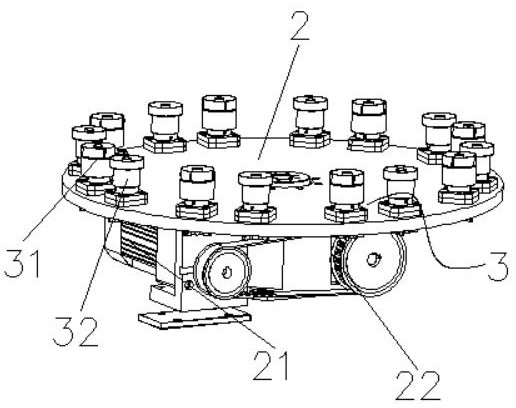

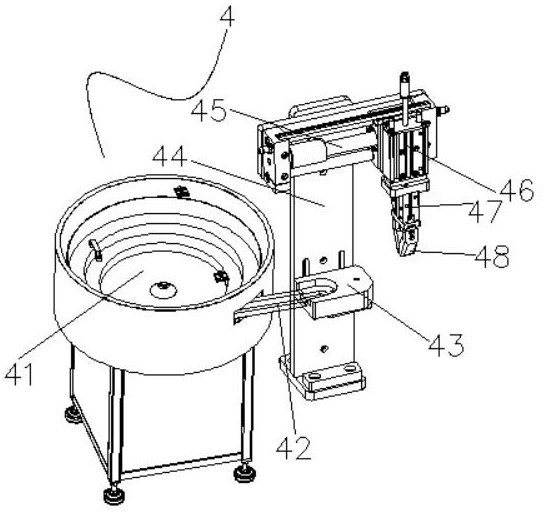

[0019] see figure 1 , an automatic assembly machine for origami filter elements, including a frame 1, a turntable 2 with a drive motor 21 and a divider 22, several groups of product fixtures 3, an upper cover vibration feeding mechanism 4, a lower cover vibration feeding mechanism 5, a point Glue mechanism 6, origami feeding conveyor belt 7, buckle cover assembly mechanism 8, compacting mechanism 9, blanking mechanism 10 and blanking conveyor belt 11, and described turntable 2 is placed in the center of frame 1, as figure 2 As shown, the product fixtures 3 are evenly distributed on the turntable 2 and include an upper cover fixture 31 and a lower cover fixture 32, each set of fixtures includes two upper and lower cover fixtures, and the upper cover vibrates and feeds Mechanism 4, lower cover vibrating feeding mechanism 5, glue dispensing me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com