Flat screen printing machine for polyester active printing and dyeing

A printing machine and printing screen technology, applied in screen printing machines, printing machines, screen printing, etc., can solve the problems of low installation efficiency, achieve high stability, simple operation, and improve the efficiency of disassembly and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

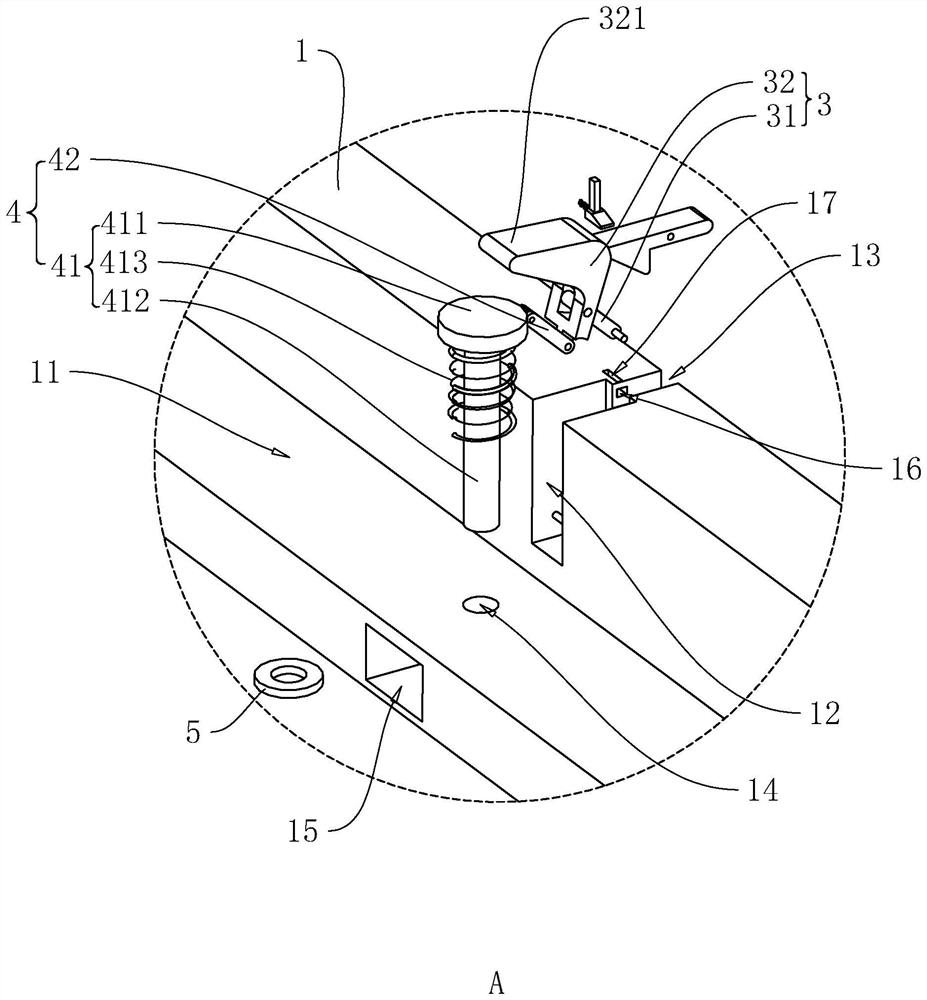

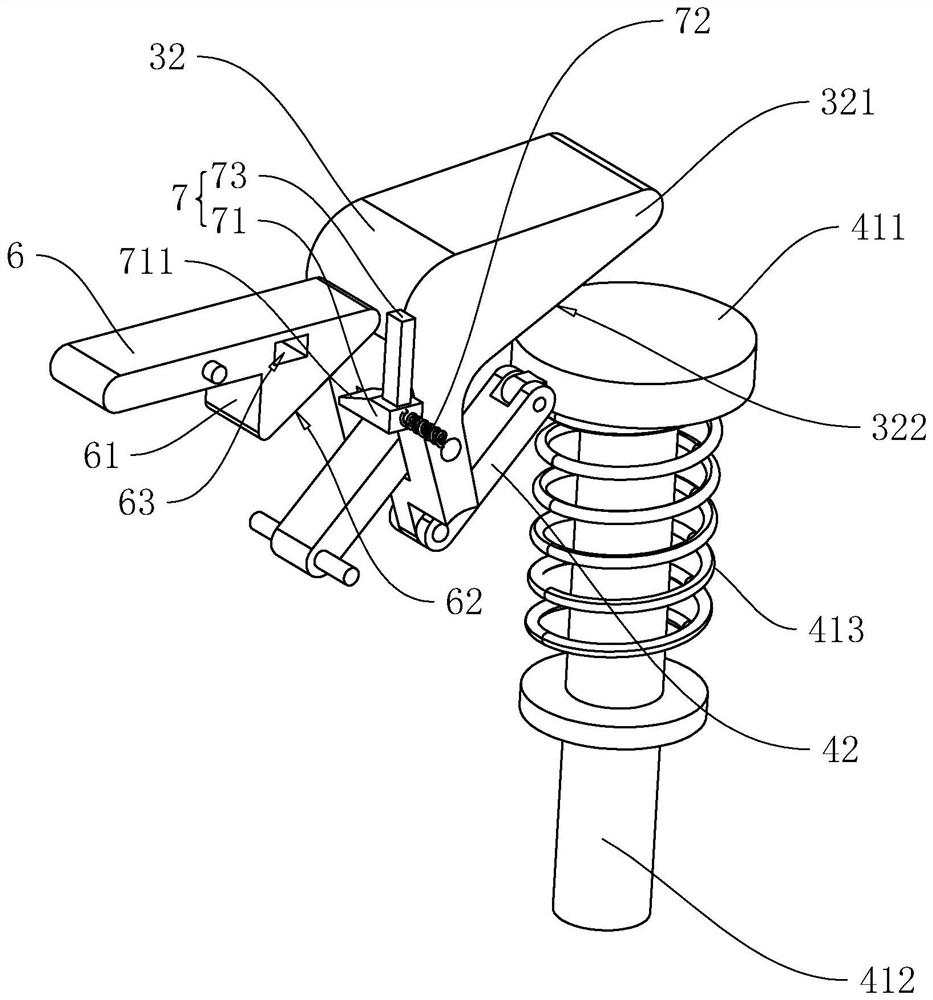

[0033] The following is attached Figure 1-3 The present invention is described in further detail.

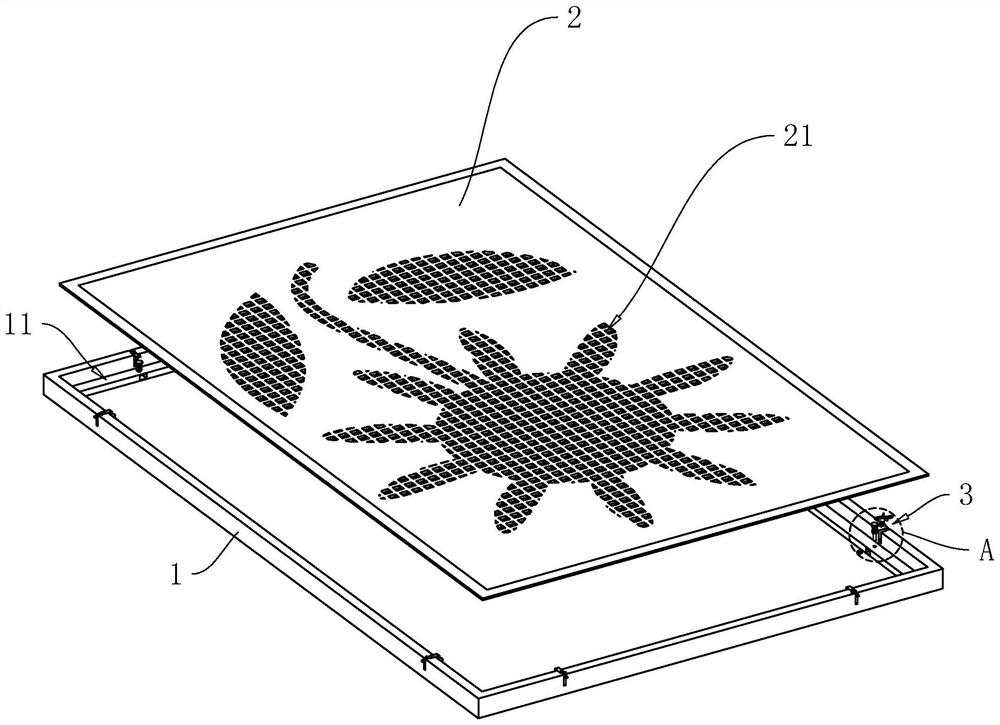

[0034] The embodiment of the present application discloses a flat screen printing machine for reactive printing and dyeing of polyester, referring to figure 1 , including the printing screen lifting frame 1 and the plane printing screen 2, the printing screen lifting frame 1 is in the shape of a four-frame, and the printing screen groove 11 for putting the flat printing screen 2 into it is arranged on the inner side of the printing screen lifting frame 1, and the printing screen The position of the lifting frame 1 surrounded by the printing screen tank 11 is hollowed out, and the hollowed out position is used for the dye on the plane printing screen 2 to penetrate to dye the fabric.

[0035] In application, the printing screen lifting frame 1 can be installed on the flat screen printing machine by means of a cylinder (not related to the main points of the scheme, not shown in ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap