Crown spring terminal and assembly process thereof

An assembly process and crown spring technology, which is applied in the manufacture of coupling devices, components of connecting devices, and contact pieces, can solve the problems of high inner and outer diameter size range, inconvenient operation, gaps, etc., and achieve convenient and easy molding process Effect of operation and simplification of assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

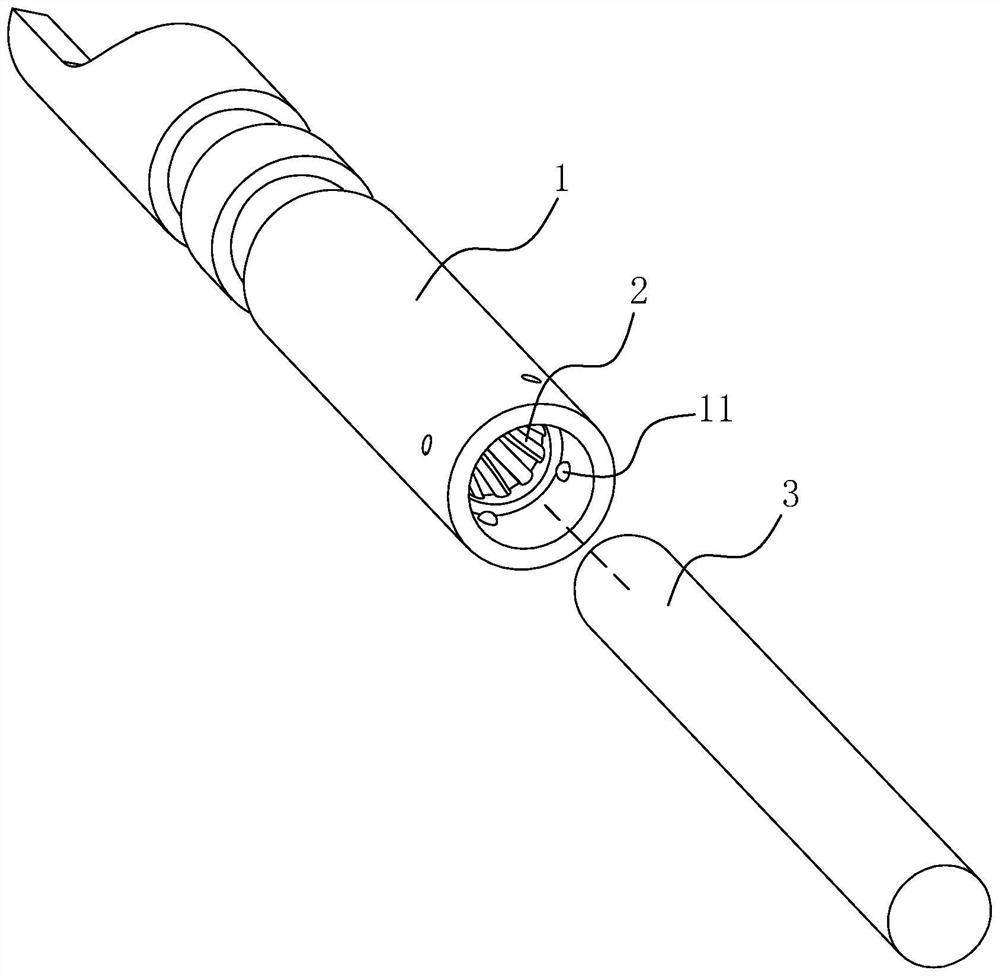

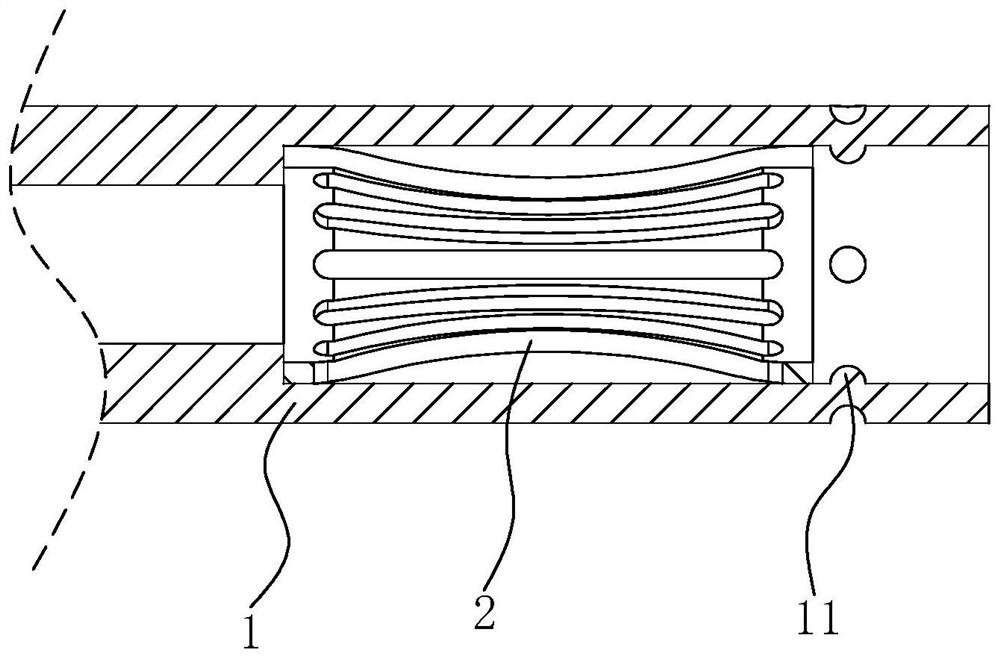

[0040] refer to figure 1 The crown spring terminal includes a female terminal 1, a male terminal 3 and a crown spring 2. The female terminal 1 and the male terminal 3 are used for mutual connection. The connecting end of the female terminal 1 is cylindrical, and the crown spring 2 is installed on the connection of the female terminal 1 In the end, the connecting end of the male terminal 3 is in the shape of a cylindrical needle, and is used for connecting in the crown spring 2. When in use, insert the connecting end of the male terminal 3 into the crown spring 2 to realize the connection between the male terminal 3 and the female terminal 1, so as to transmit current or signal.

[0041] refer to figure 1 and figure 2, the crown spring 2 is cylindrical, and the cross-section is circular, and the diameter of the crown spring 2 changes uniformly along its axial direction. In this embodiment, the diameter of the crown spring 2 gradually decreases from both ends to the middle. I...

Embodiment 2

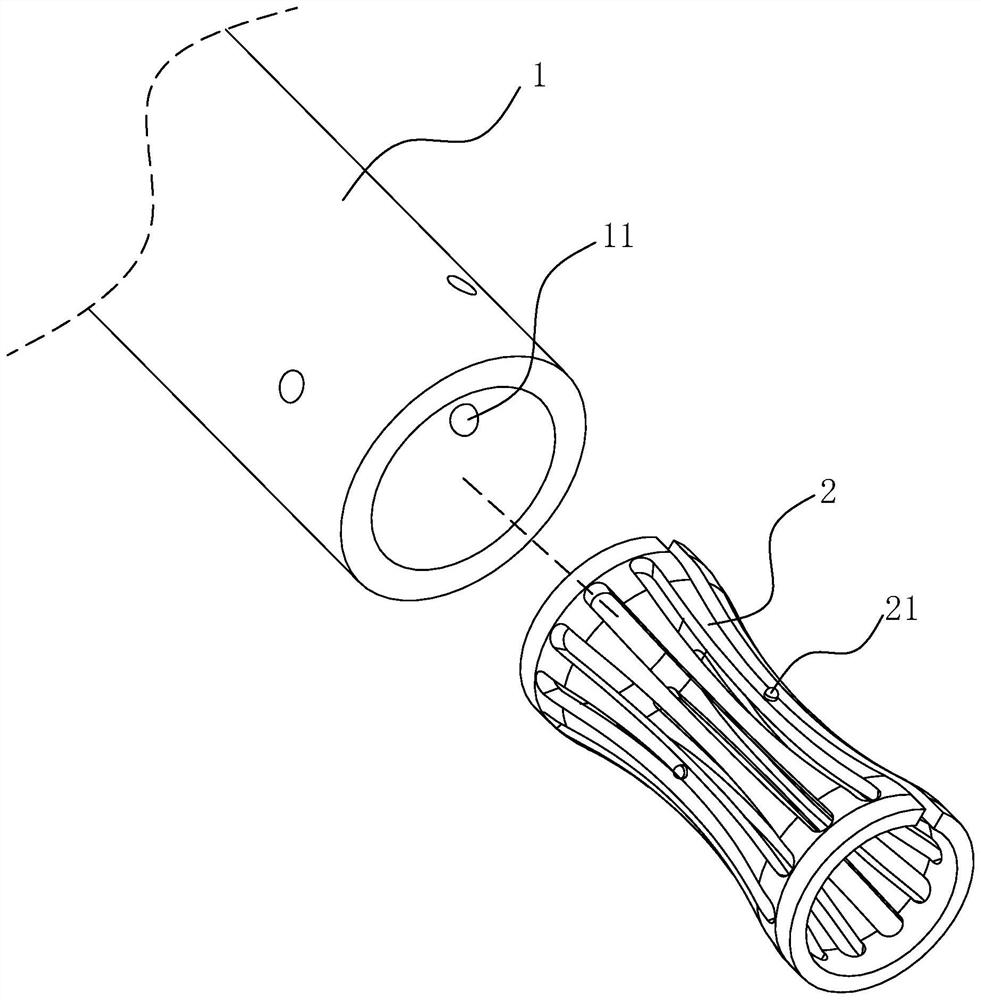

[0045] refer to image 3 The difference between this embodiment and Embodiment 1 is that the outer wall of the crown spring 2 with the smallest cross-sectional size is formed with a second protrusion 21, and several second protrusions 21 are evenly arranged around the circumference of the crown spring 2. The protrusion 21 can be integrally formed with the crown spring 2, and can also be formed by cold extrusion from the inside of the crown spring 2 after the crown spring 2 is formed. the distance between the outer walls.

[0046] When the male terminal 3 is inserted into the crown spring 2, the middle part of the crown spring 2 is opened outwards. At this time, the middle part of the crown spring 2 clamps the male terminal 3 tightly, and the second protrusion 21 is in close contact with the inner wall of the female terminal 1. , thereby effectively improving the connection strength and stability between the crown spring 2 and the male terminal 3 and the female terminal 1 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com