Portable large steel pipe end face leveling device

A leveling device and a convenient technology, which are applied in the field of portable large-scale steel pipe end leveling devices to achieve good fixing effect, good fixing effect, and the effect of improving friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

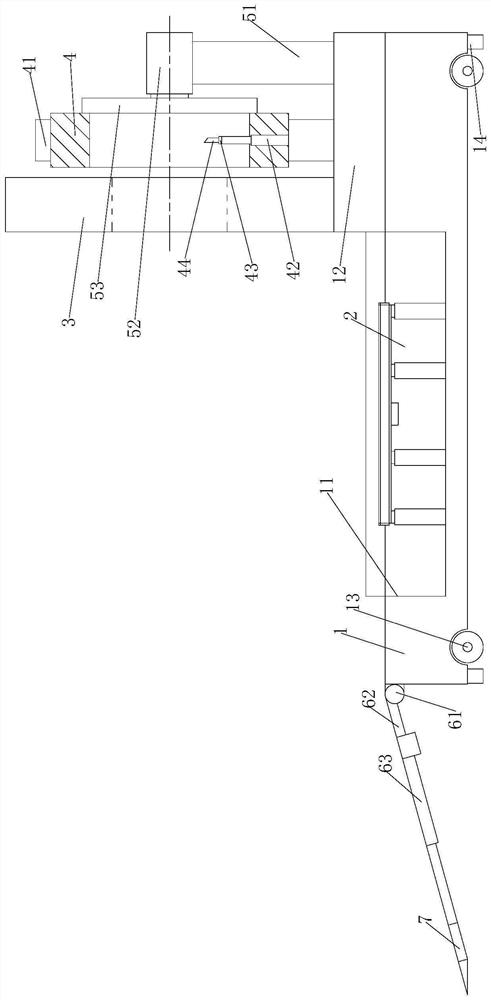

[0027] Example. The convenient large-scale steel pipe end face leveling device is composed of Figure 1-5 As shown, it includes a main base 1, a telescopic slope unit rotated at one end of the main base 1, a rotating jacking mechanism 2 located above the middle of the main base 1, and a steel pipe cutting unit located above the other end of the main base 1; the steel pipe The cutting unit includes a steel pipe fixing mechanism 3 and a cutting mechanism arranged sequentially along the main base 1 from inside to outside; the bottom of the steel pipe cutting unit is connected to the main base 1 through the installation base 12; The groove 11 corresponding to the mechanism 2, the bottom of the main base 1 is evenly provided with a plurality of motor-driven rollers 13 and a plurality of hydraulic legs 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com