PMC composite material-based laser tool compatible with multiple products

A composite material and laser technology, which is applied in the direction of laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems that objects of different sizes cannot be fixed and processed, inconvenient to adjust the position, troublesome to use, etc., to achieve convenient operation and easy installation , Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

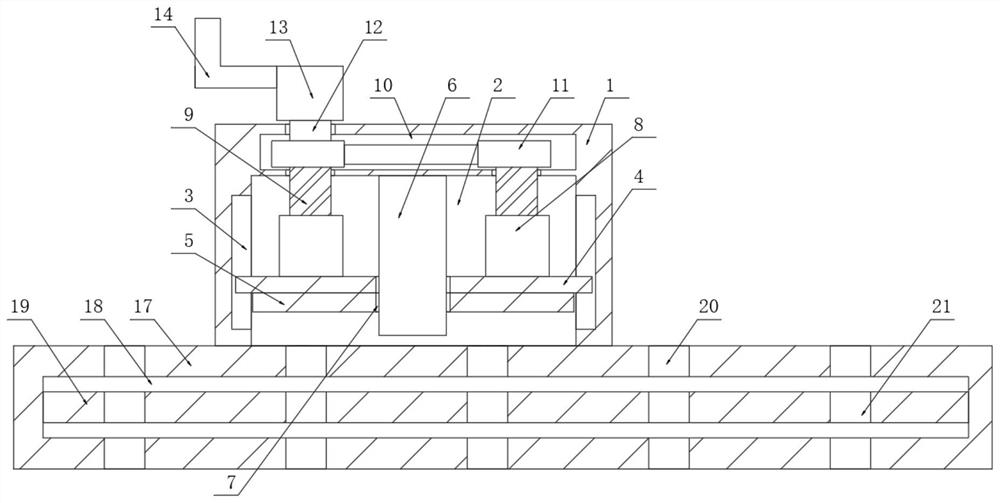

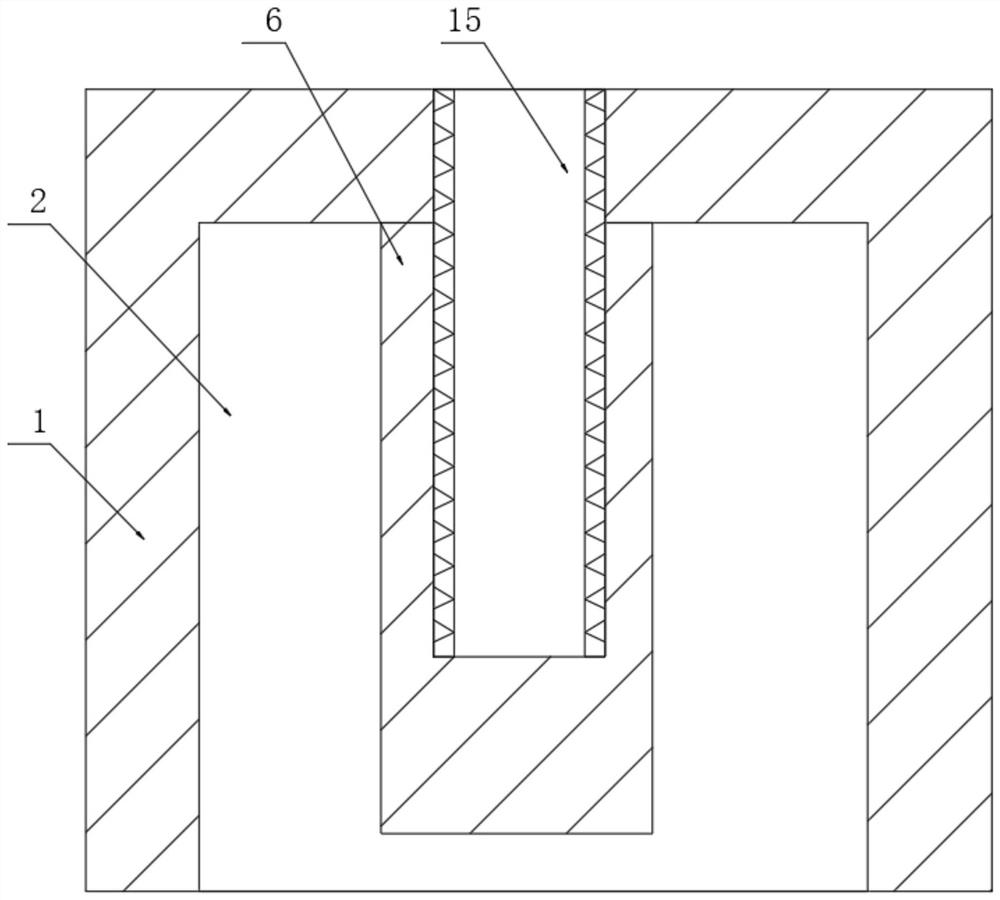

[0031] Such as figure 1 As shown, the embodiment of the present invention provides a laser tooling compatible with multiple products based on PMC composite materials, including a laser tooling compatible with multiple products, including a support base 1, and the lower surface of the support base 1 is provided with a first Groove 2, the four sides of the inner wall of the first groove 2 are provided with chute 3, the inner walls of a plurality of chute 3 are all connected to the bottom plate 4 through sliding blocks, and the lower surface of the bottom plate 4 is fixedly connected to the upper permanent magnet. Block 5, the upper side of the inner wall of the first groove 2 is fixedly connected with the limit column 6, and the upper side surface of the base plate 4 and the lower side surface of the upper permanent magnet block 5 are all provided with slide holes 7, and the inner walls of the two slide holes 7 and The rod walls of the limit post 6 are in contact with each other...

Embodiment 2

[0033] Such as figure 1 As shown, the embodiment of the present invention provides a laser tooling compatible with multiple products based on PMC composite materials, including laser tooling compatible with multiple products. The upper surface of the bottom plate 4 is fixedly connected with a plurality of connection barrels 8, and multiple The inner walls of each connecting barrel 8 are screwed with screw rods 9, the upper surface of the support base 1 is provided with a first cavity 10, and the upper ends of a plurality of screw rods 9 run through the lower side of the inner wall of the first groove 2 to Inside the first cavity 10, pulleys 11 are fixedly connected to the upper ends of the plurality of screw rods 9, and the opposite surfaces of the plurality of pulleys 11 are connected by belt rotation, and the upper surface of one of the pulleys 11 is fixedly connected to the first pulley 11. Rotating rod 12, the upper end of the first rotating rod 12 runs through the upper s...

Embodiment 3

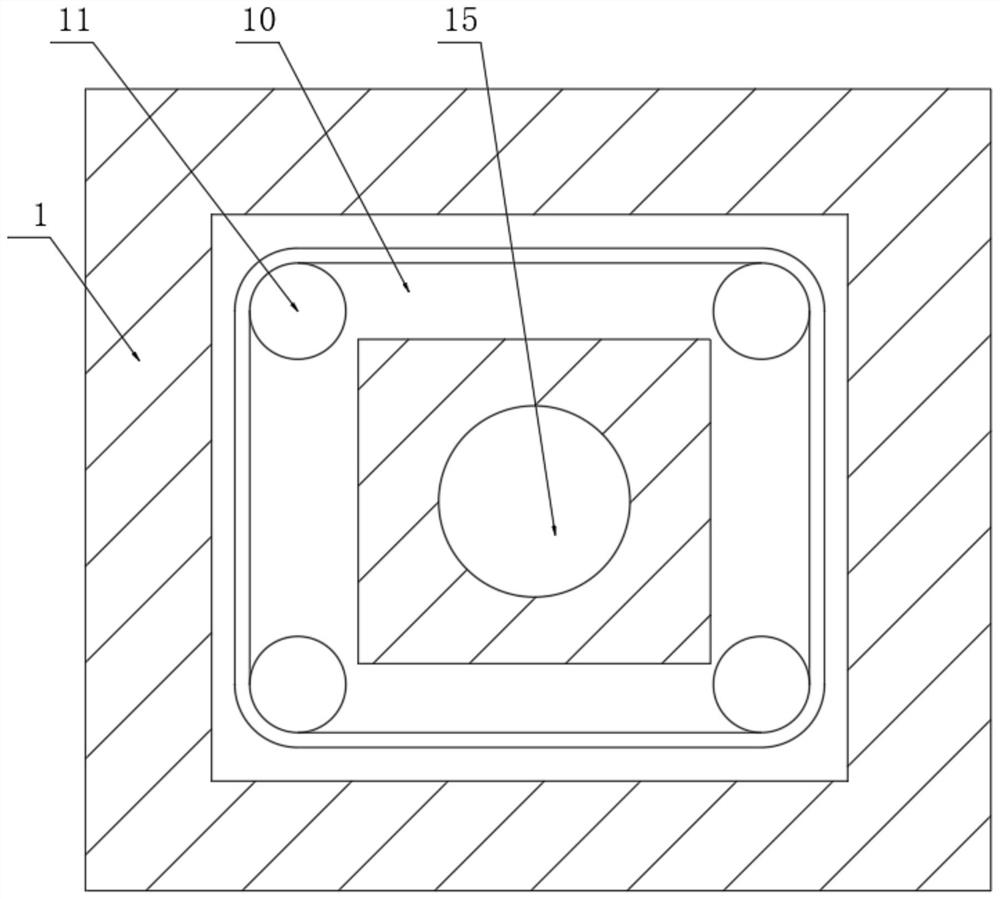

[0035] Such as image 3 and Figure 4 As shown, the embodiment of the present invention provides a laser tooling compatible with multiple products based on PMC composite materials, including a laser tooling compatible with multiple products, the upper surface of the support base 1 and the upper surface of the limit post 6 A first threaded connection groove 15 is jointly provided, and a plurality of second threaded connection grooves 16 are provided on the four sides of the upper side surface of the support base 1 located at the first threaded connection groove 15, which is convenient for installing other equipment and is more convenient. It is convenient to disassemble the object, and at the same time, it is convenient for the operator to operate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com