Water bath stretcher for stretching net

A water-bath stretching and stretching net technology, which is applied in the field of plastic net material processing equipment, can solve the problems of difficult placement, large floor space, and unsuitable lateral stretching requirements for plastic stretch nets, etc., achieving low cost, Easy maintenance and high maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

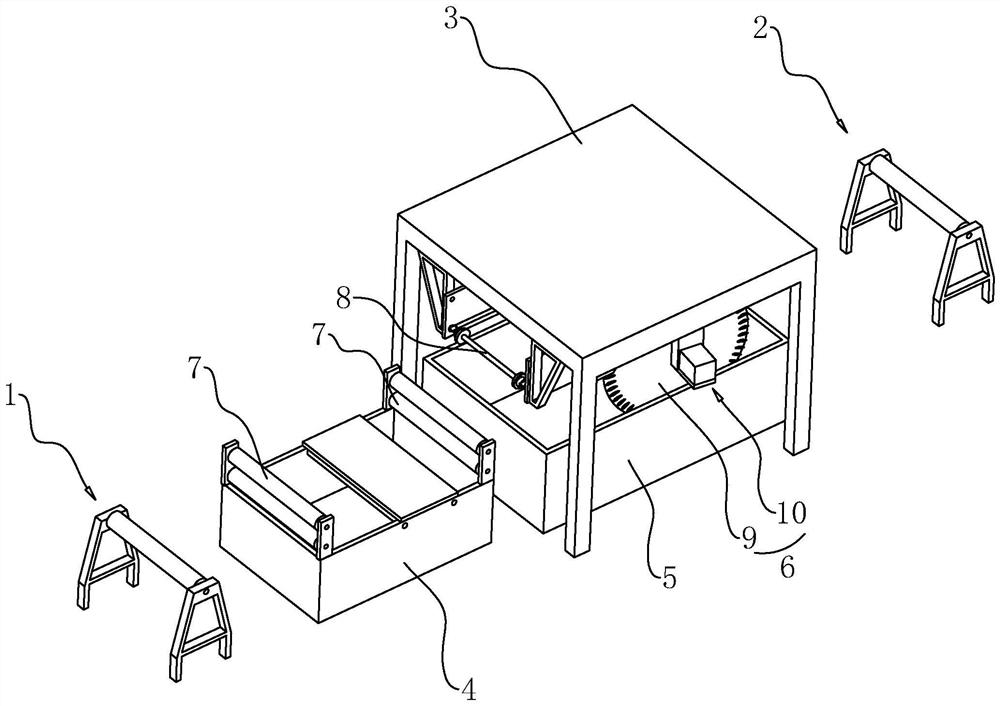

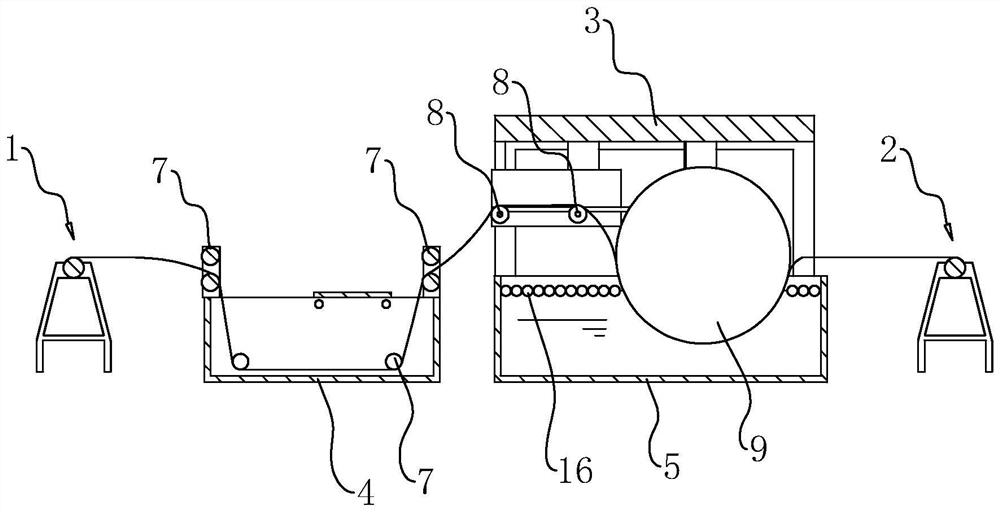

[0044] The embodiment of the present application discloses a water-bath stretching machine for stretching a net. refer to figure 1 and figure 2 , The stretching line includes an unwinding mechanism 1, a water bath stretching machine and a winding mechanism 2. The water-bath stretching machine includes a machine base 3, a water-bath preheating pool 4, a guide roller group, a water-bath heat preservation pool 5, and a stretching mechanism 6. Wherein the unwinding mechanism 1, the water bath preheating pool 4, the water bath heat preservation pool 5 and the winding mechanism 2 are arranged in sequence. The stretching mechanism 6 is installed on the machine base 3 , and the stretching mechanism 6 is located in the water bath heat preservation tank 5 . The set of guide rollers is used to guide the stretched net to pass through the water bath preheating pool 4 and the stretching mechanism 6 in sequence. The water bath preheating pool 4 and the water bath heat preservation pool ...

Embodiment 2

[0059] The difference between embodiment 2 and embodiment 1 is that, referring to Figure 5 and Figure 6 , two stretched cymbals 9 form stretched cymbals group 19. There are several stretching cymbal groups 19 arranged at intervals along the feeding direction of the stretching wire. The guide roller set also includes a driving roller 28, which is arranged between two adjacent stretching cymbal sets 19. Stretch net passes around transmission roller 28 earlier after the stretching cymbal group 19 of wherein front, then is wound on the stretching cymbal group 19 of rear, thereby fully utilizes the peripheral circumference of stretching cymbal 9.

[0060] When in use, the number of stretched cymbal groups 19 to be used can be selected according to actual working conditions. If the width of the stretched net needs to be stretched laterally is larger, then select multiple groups of stretched cymbals 19, so that the stretched net is laterally stretched to the required width after...

Embodiment 3

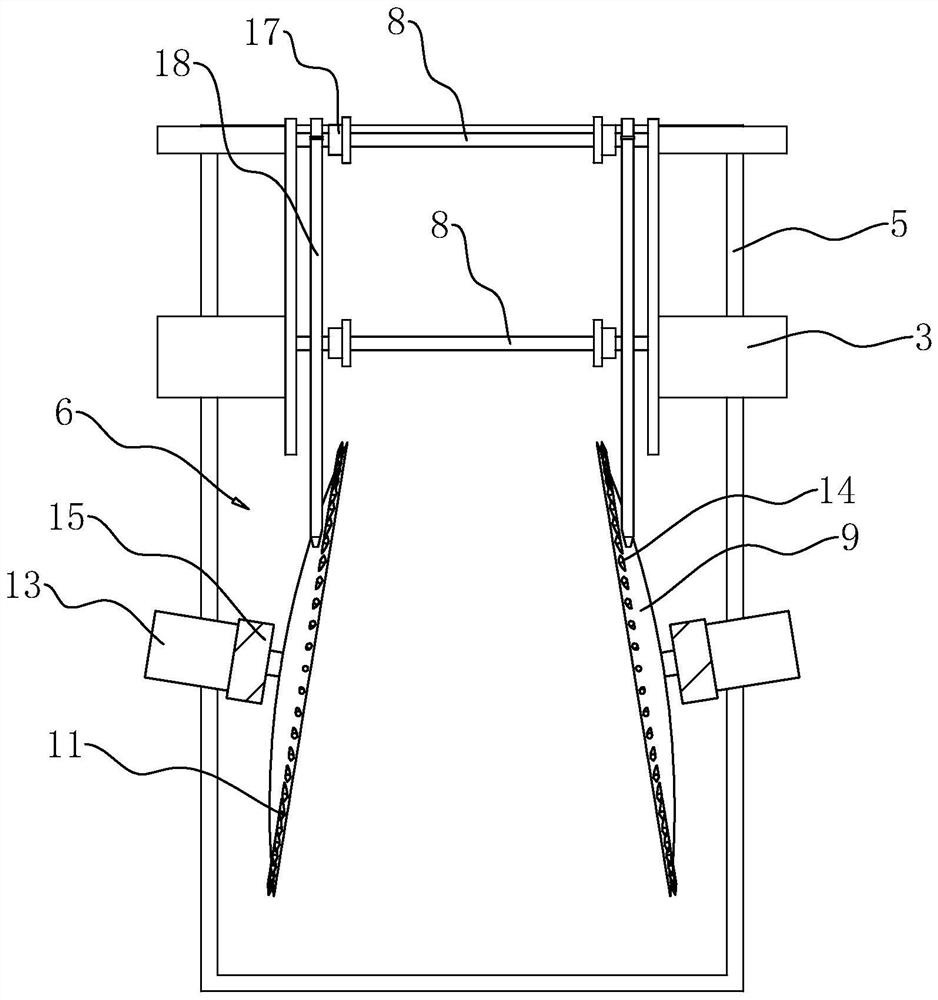

[0062] The difference between embodiment 3 and embodiment 1 is that, referring to Figure 7 and Figure 8 , also includes two second drive assemblies 20, one stretch cymbal 9 corresponds to one second drive assembly 20. The second driving assembly 20 is used to drive the stretched cymbal 9 to rotate relative to the base 3 . To adjust the width of the feed end of the stretching mechanism 6 and the width of the discharge end, it can be better applicable to more working conditions.

[0063] Specifically, the limiting roller 8 near the feeding end of the stretched cymbal 9 is set as the first roller. The limiting wheel 17 on the first roller is slidably connected to the first roller along the axial direction. The second driving assembly 20 includes a screw rod 21 , a push block 22 and a servo motor 23 . The screw mandrel 21 is parallel to the first roller and the screw mandrel 21 is screwed on the machine base 3, the body of the servo motor 23 is fixedly installed on the base,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap