Multi-station bidirectional working organic fertilizer bagging equipment

A two-way work, organic fertilizer technology, used in conveyor objects, packaging sealing/fastening, external support, etc., can solve the problems of wasting time, reducing work efficiency, restrictions, etc., to improve the number of workstations, improve work efficiency, Reduce the effect of jitter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

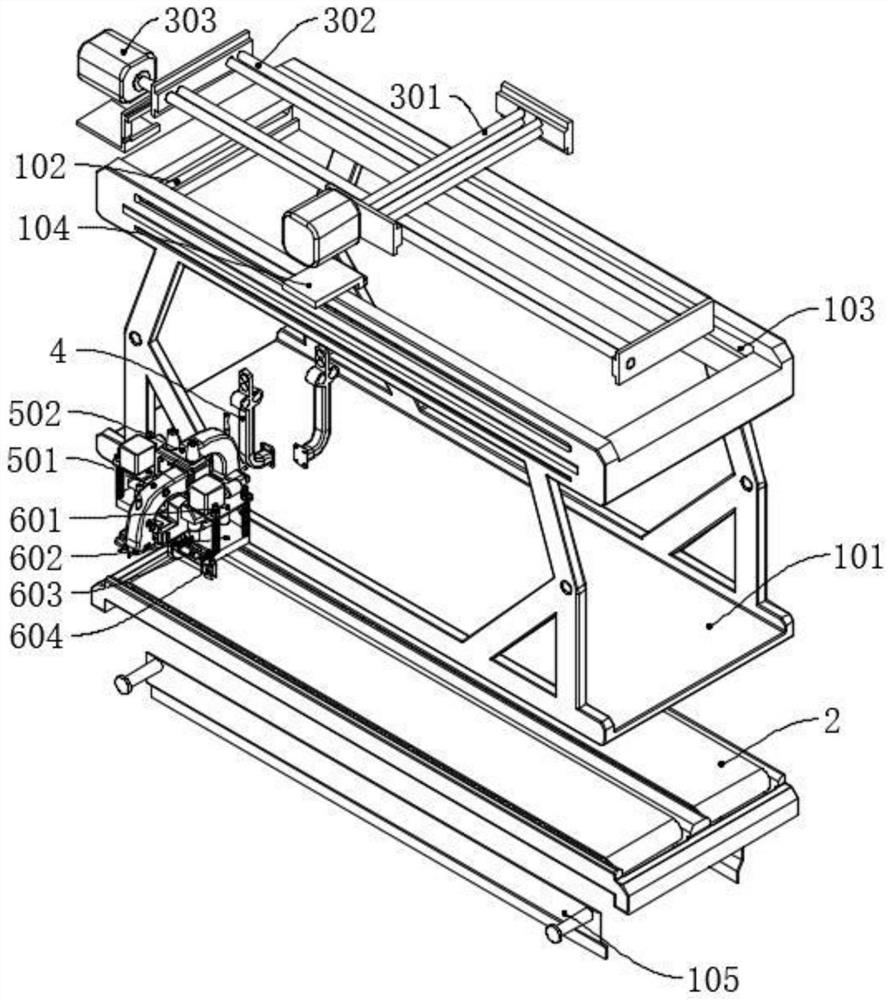

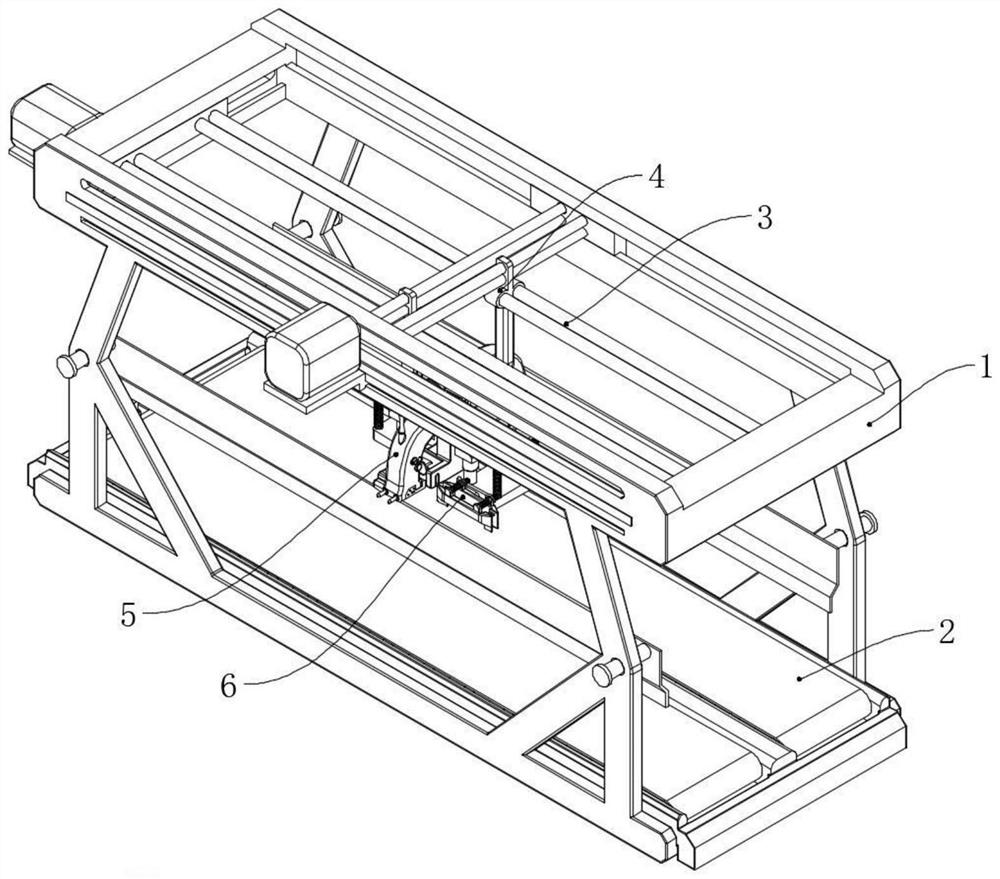

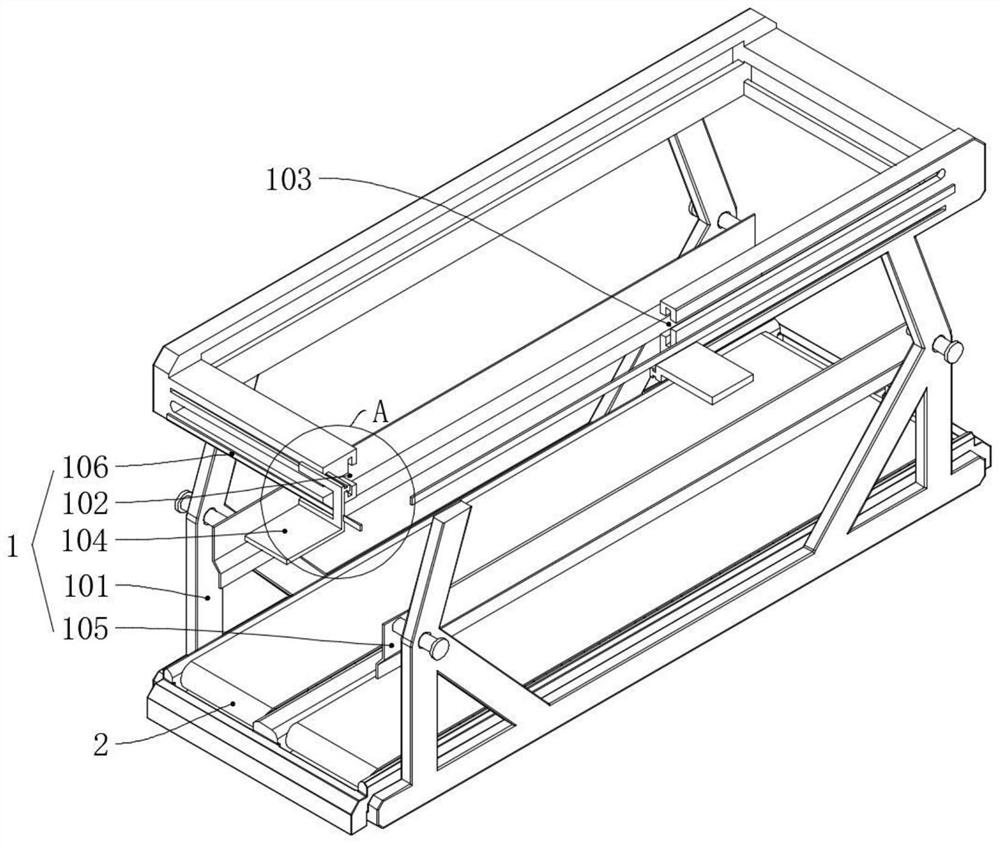

[0036] Example: Please refer to Figure 1 to Figure 8 :

[0037] The present invention proposes a multi-station two-way working organic fertilizer bag sealing equipment, comprising: an installation mechanism 1; a conveying mechanism 2 is installed under the interior of the installation mechanism 1, and the conveying mechanism 2 is electrically connected to the outside; The direction changing mechanism 3 is installed above the interior, and the T-shaped protrusions of the transverse bar 301 and the longitudinal bar 302 of the direction changing mechanism 3 are inserted into the positioning groove A102 and the positioning groove B103 of the installation mechanism 1; The connection mechanism 4, and the through hole of the connector 401 of the connection mechanism 4 is inserted with a transverse rod 301; the packaging mechanism 5 is installed under the connection mechanism 4, and the main body 501 of the packaging mechanism 5 is connected to the connector 401 of the connection mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com