Diamond-silicon carbide composite material, preparation method and electronic equipment

A composite material and diamond technology, applied in the field of thermal management application materials, can solve problems such as the decline of the comprehensive performance of composite materials, and achieve the effect of avoiding negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

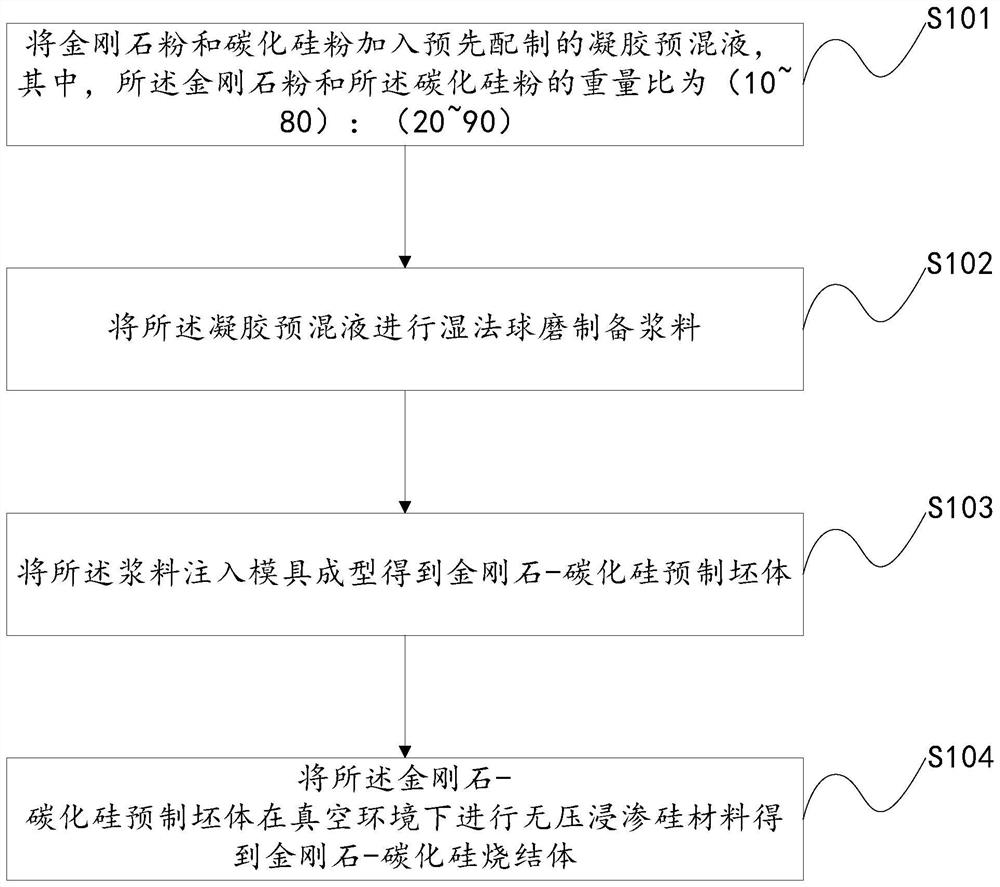

[0032] combine figure 1 As shown, a method for preparing a diamond-silicon carbide composite material is provided in an embodiment of the present invention, including:

[0033] S101. Add diamond powder and silicon carbide powder to the pre-prepared gel premix, wherein the weight ratio of the diamond powder to the silicon carbide powder is (10-80):(20-90).

[0034] The diamond is generally available in the market, and the gel premix is pre-prepared. The premix can use the acrylamide gel system premix. When configuring the acrylamide gel system premix, add a certain amount of acrylamide and methylenebisacrylamide , wherein acrylamide and methylenebisacrylamide account for 2-10% and 0.2-1% of the total mass of the powder respectively, the powder here includes diamond powder and silicon carbide powder, and the volume of the powder is the same as that of the acrylamide condensate The total volume of the glue system premix is 100%. The weight ratio of diamond powder and silicon...

Embodiment 2

[0048] The embodiment of the present invention also provides a second diamond-silicon carbide composite material preparation method, including:

[0049] S201. First, the acrylamide gel system is used to form a diamond-silicon carbide preform, and the process flow is as follows:

[0050] Configure acrylamide gel system premix night, the premix solution contains a certain amount of acrylamide, methylenebisacrylamide and other organic chemical reagents, wherein acrylamide and methylenebisacrylamide account for 2% of the total powder mass respectively ~10%, 0.2~1%. Add diamond powder and silicon carbide powder with a certain gradation respectively. The gradation is the distribution of particle sizes at all levels of the aggregate, which can be determined through sieve analysis tests. (wherein the powder volume and the premixed volume are 100%) ball milling for 24 hours, vacuum degassing for 30 minutes, adding a catalyst and an initiator, injecting the slurry into a mold, and dryi...

Embodiment 3

[0055] The embodiment of the present invention also provides a third diamond-silicon carbide composite material preparation method, including:

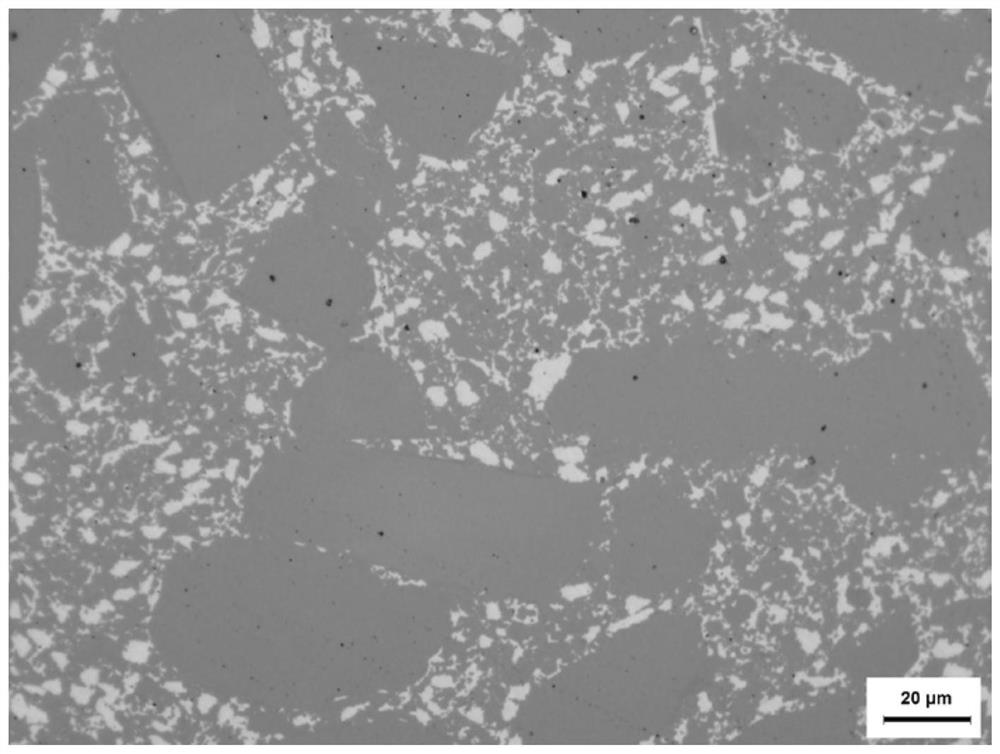

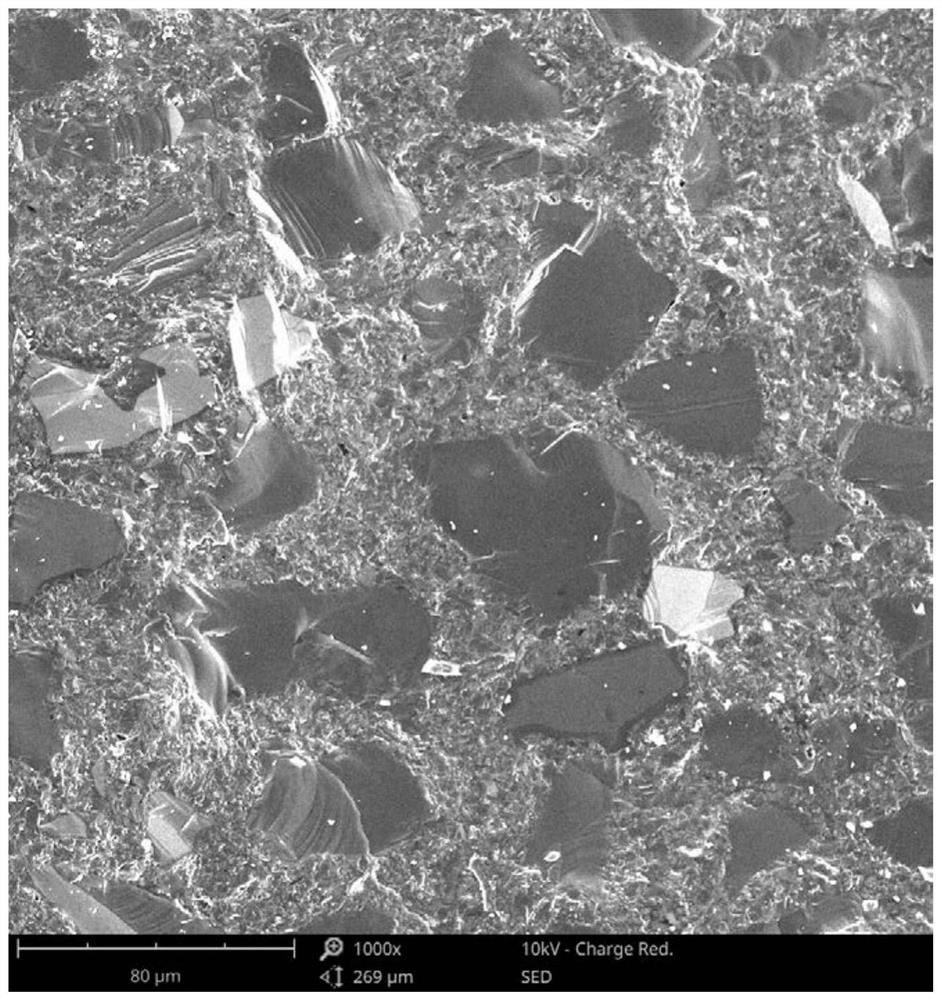

[0056] S301. First, add a certain amount of acrylamide, methylenebisacrylamide and other organic chemical reagents to configure the gel system premix, wherein acrylamide and methylenebisacrylamide account for 5% and 0.4% of the total mass of the powder, respectively. %, select silicon carbide powder and diamond powder with different particle sizes and add them into the premixed mixture with a mass fraction of 16:84, wherein the volume of the powder and the volume of the premixed mixture are 100% in total, after stirring evenly, ball mill for 24 hours, and the slurry is pumped Vacuum for 30 minutes, add the catalyst tetramethylethylenediamine and the initiator ammonium persulfate successively, wherein the catalyst and the initiator account for 0.03-0.09% and 0.3-0.9% of the total volume of the slurry respectively, and add them at a cert...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap