Blast chamber cooling with guided airflow

A technology of air flow and air, which is applied in the direction of coolers, household refrigeration devices, cooling fluid circulation devices, etc., to achieve the effect of improving efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

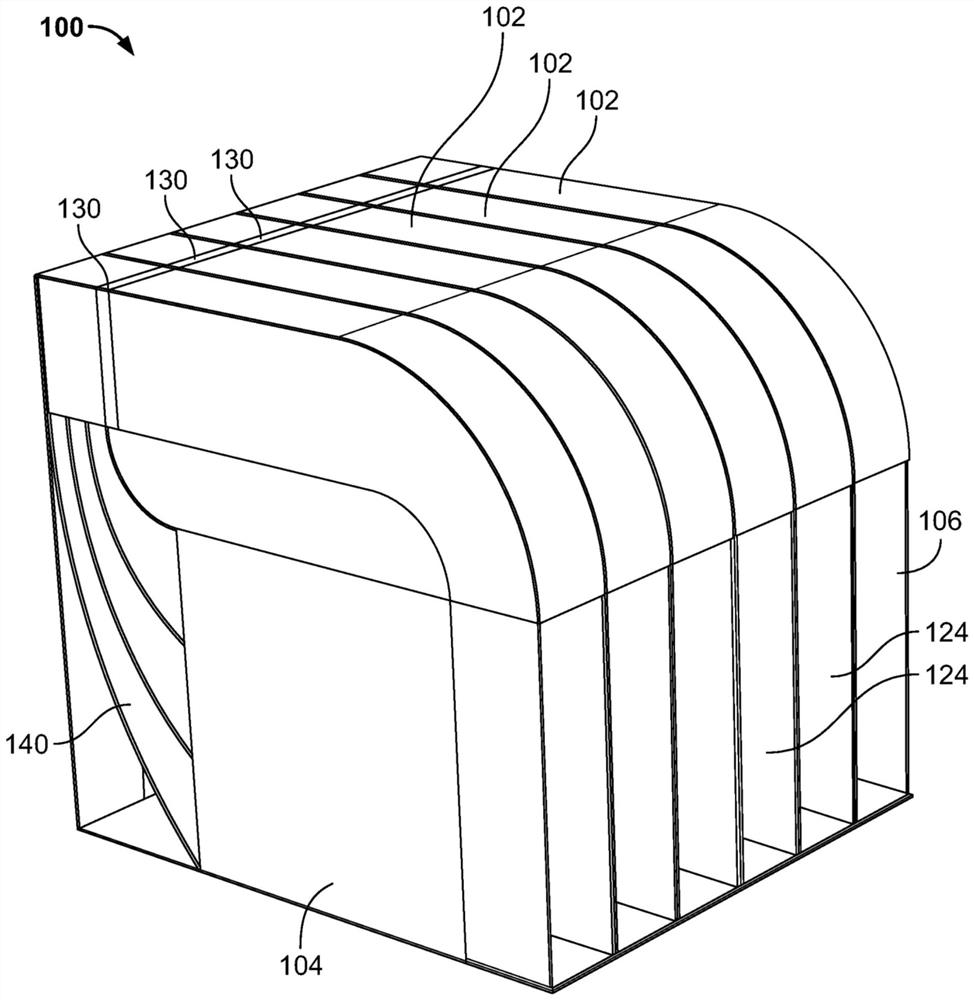

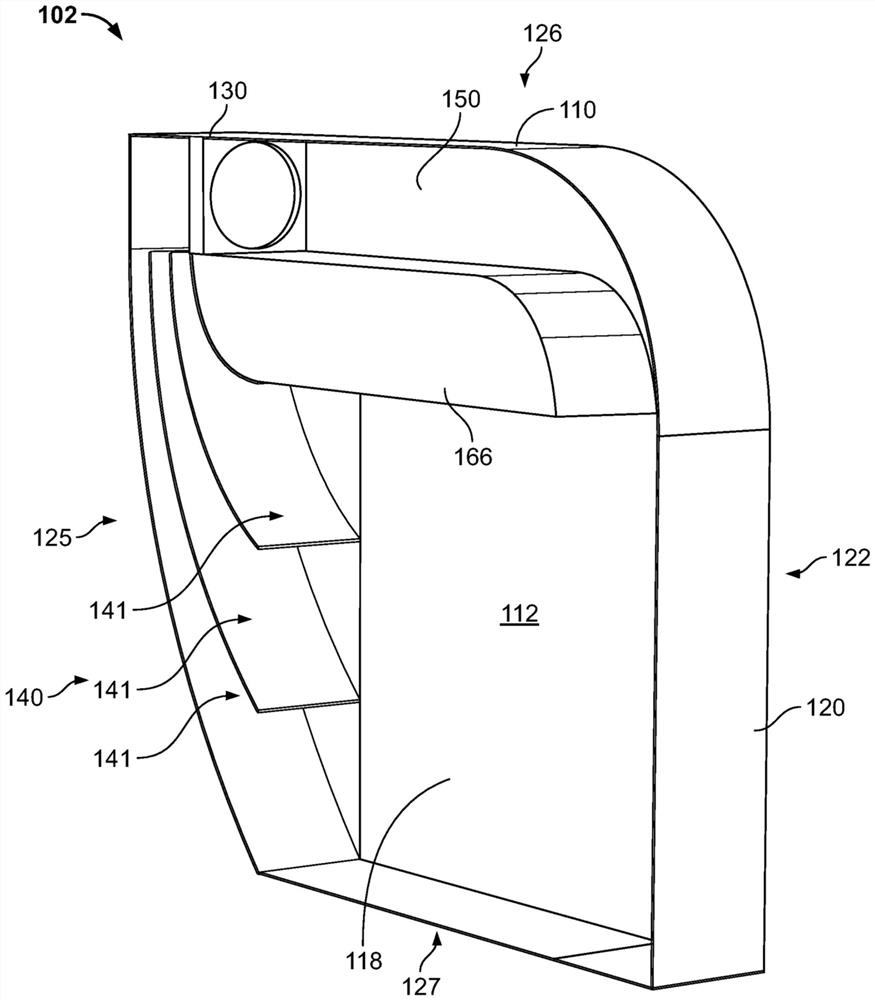

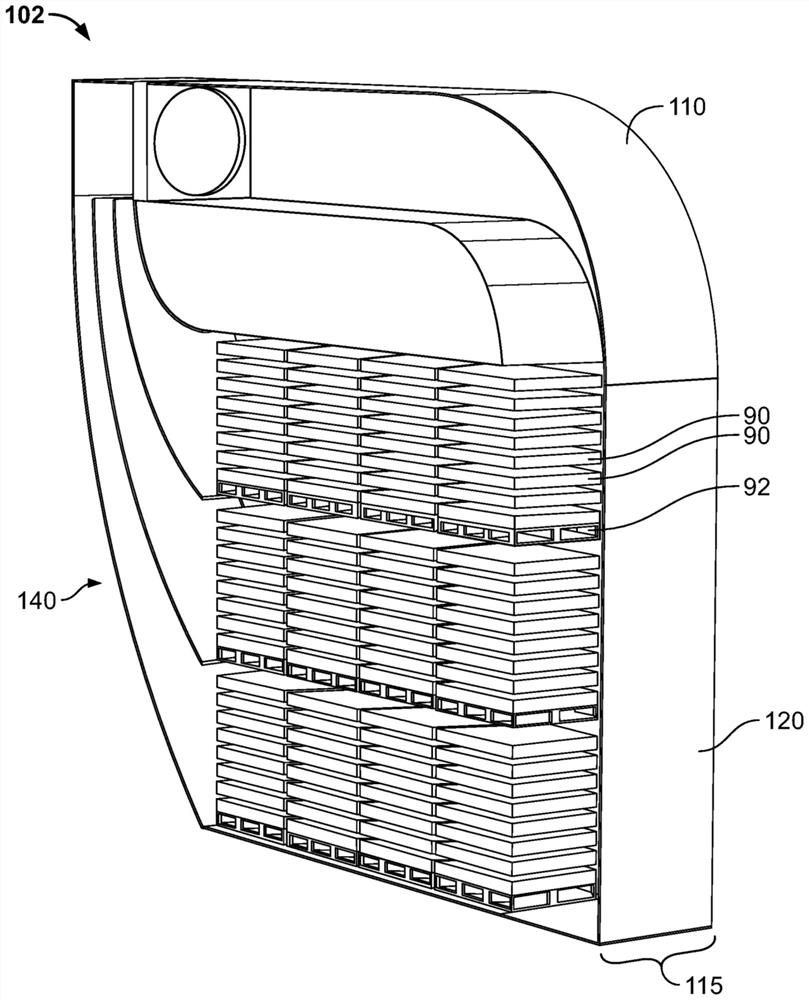

[0040] Various embodiments of methods and systems for cooling (eg, blast freezing) items, such as perishable food, that have previously been packaged as groups of items onto shipping and storage pallets are described below. The systems and techniques discussed herein provide a simple and easily scalable blast chamber that prevents short circulation of air flow through items in the blast chamber. Each blower chamber may contain a plurality of suction channels providing independent fluid paths for directing air drawn from different rows in the blower chamber into the fans.

[0041] refer to figure 1 , the example plenum system 100 is configured to cool items loaded therein. Although the plenum system 100 is primarily described herein as a freezer, it should be understood that the plenum system 100 can be used with or without modification as a cooler. The blast chamber system 100 may include one or more blast chambers 102, each configured to receive items and operative to cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com