Method and conductor structure for producing electrical winding of electromagnetic induction device

A technology of electromagnetic induction and conductor structure, applied in the direction of transformer/inductor coil/winding/connection, transformer/inductor components, coil manufacturing, etc., can solve the problems of dangerous unbalanced state and collapse of winding structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

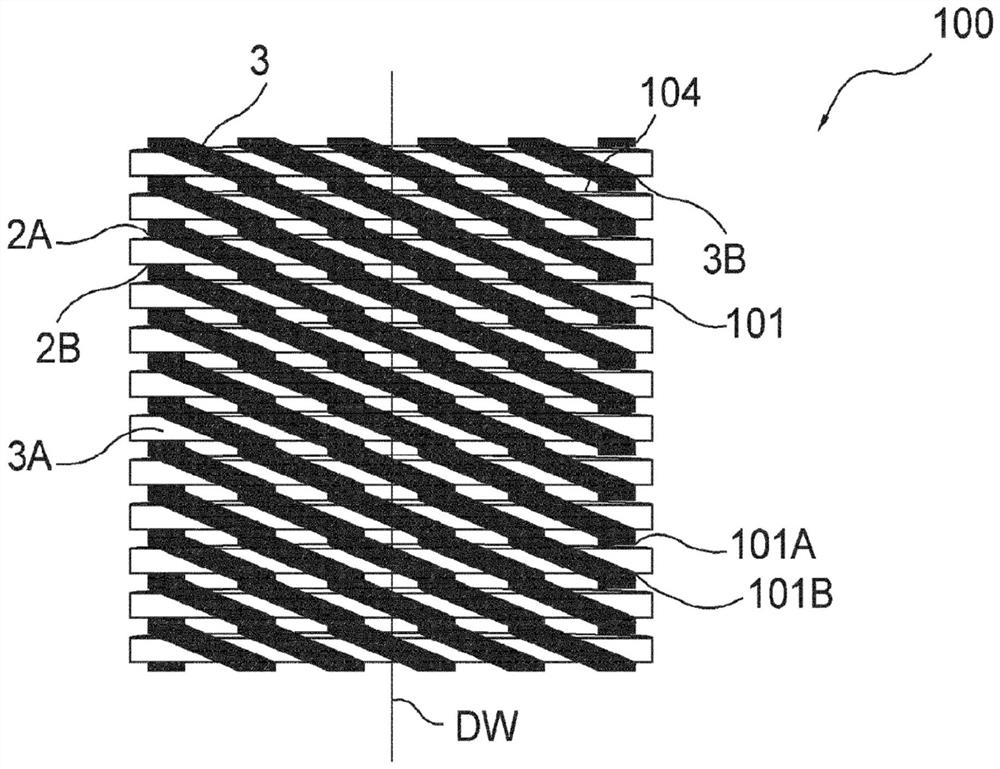

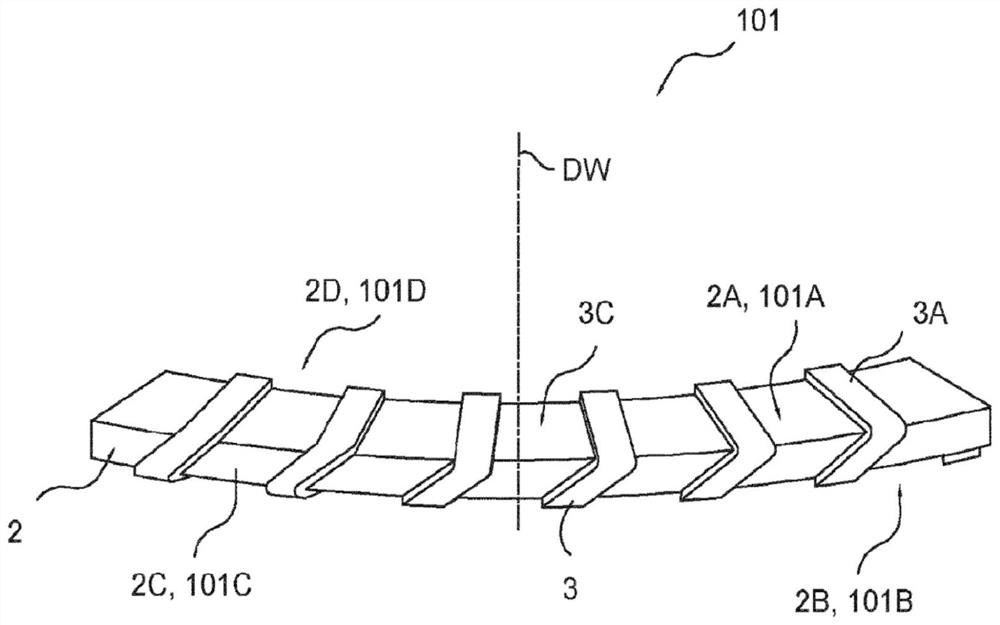

[0040] With reference to the above figures, the present invention relates to a method for manufacturing an electrical winding 100 for an electromagnetic induction device (not shown) for power transmission and distribution networks.

[0041] Such electromagnetic induction devices may be power transformers for power transmission and distribution networks, such as power transformers or distribution transformers.

[0042] The manufacturing method according to the invention comprises the steps of providing a conductor structure 1 for forming an electrical winding 100 ( image 3 , Figure 4 ).

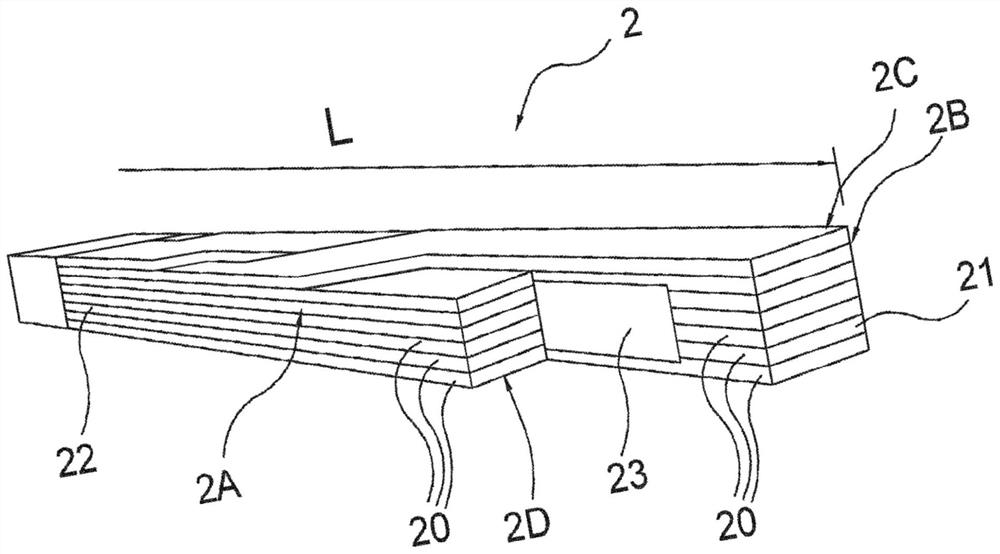

[0043] The conductor structure 1 comprises a conductor element 2 ( figure 1 ).

[0044] Preferably, the conductor element 2 is shaped to comprise the shape of an elongated parallelepiped made of electrically conductive material.

[0045] Preferably, the conductor element 2 has a suitable cross-section (eg a rectangular or square cross-section) of the opposing first and second sides 2A, 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com