Moving vehicle for loading, placing and supporting building platy objects

A technology for moving vehicles and building panels, applied in motor vehicles, goods transport vehicles, vehicles used for freight, etc., can solve the problems of inconvenient installation, falling plates, lack of supporting functions, etc., to achieve stable clamping, avoid Collision, to meet the effect of fast handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

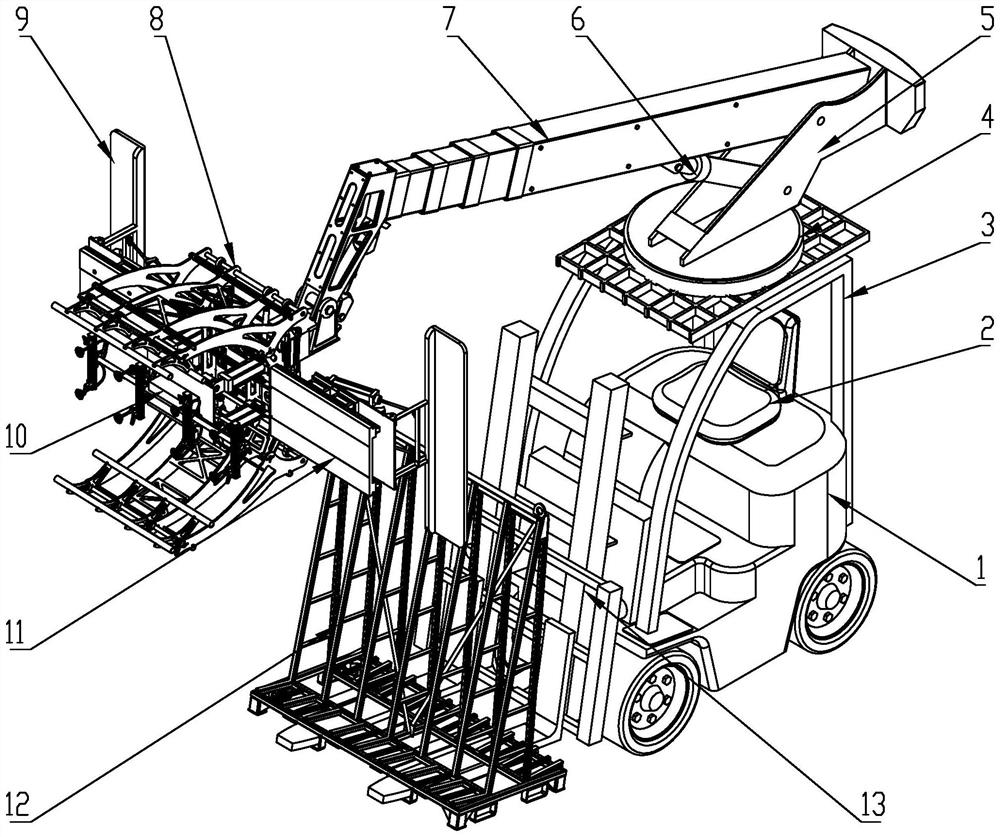

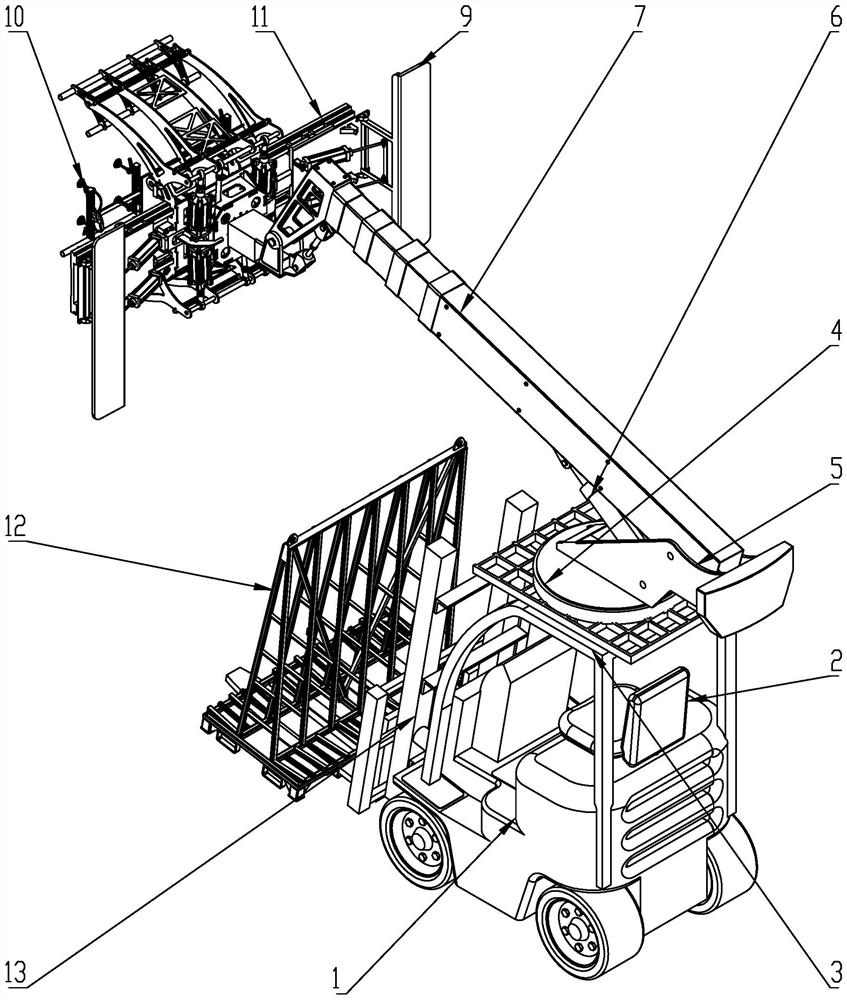

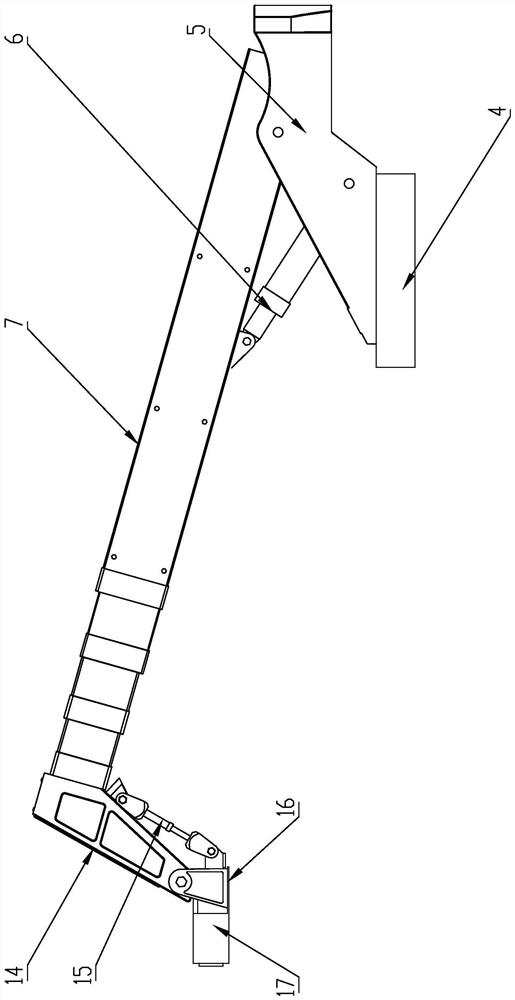

[0044] Such as Figure 1-Figure 9 As shown, the mobile vehicle for loading and placing support of the building plate includes a mobile vehicle 1, a bracket 3 is provided on the mobile vehicle 1, a rotating base 4 is installed on the top of the bracket 3, and a mounting frame 5 is fixed above the rotating base 4. , the mounting bracket 5 is hinged with an arm adjusting hydraulic lever 6 and an adjusting arm 7, the adjusting arm hydraulic lever 6 is hinged on the adjusting arm 7, the end of the adjusting arm 7 is provided with an adjusting assembly, and the adjusting assembly is provided with a clamp mechanism 8, Both sides of the gripper mechanism 8 are provided with an adjustment mechanism 11, the adjustment mechanism 11 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com