Combination tool for replacing direct-current grounding electrode line strain insulator string through horizontal rotation method and method

A DC grounding, horizontal rotation technology, applied in the direction of overhead lines/cable equipment, etc., to achieve the effect of easy disassembly, easy installation, and easy connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

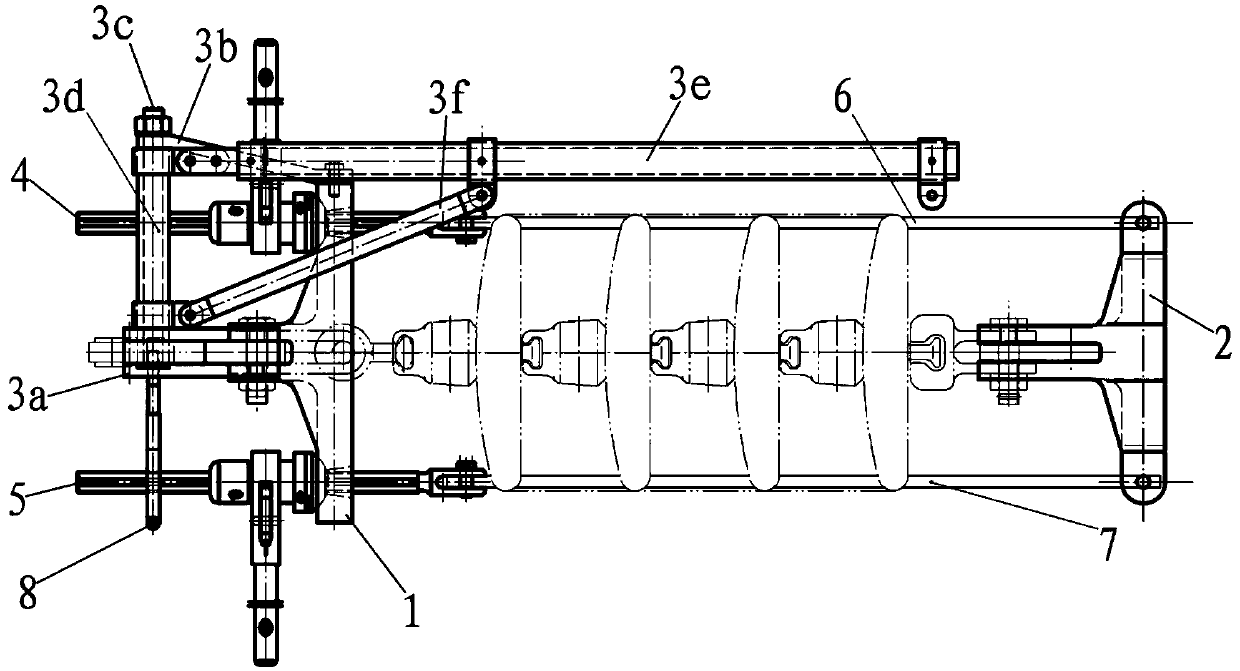

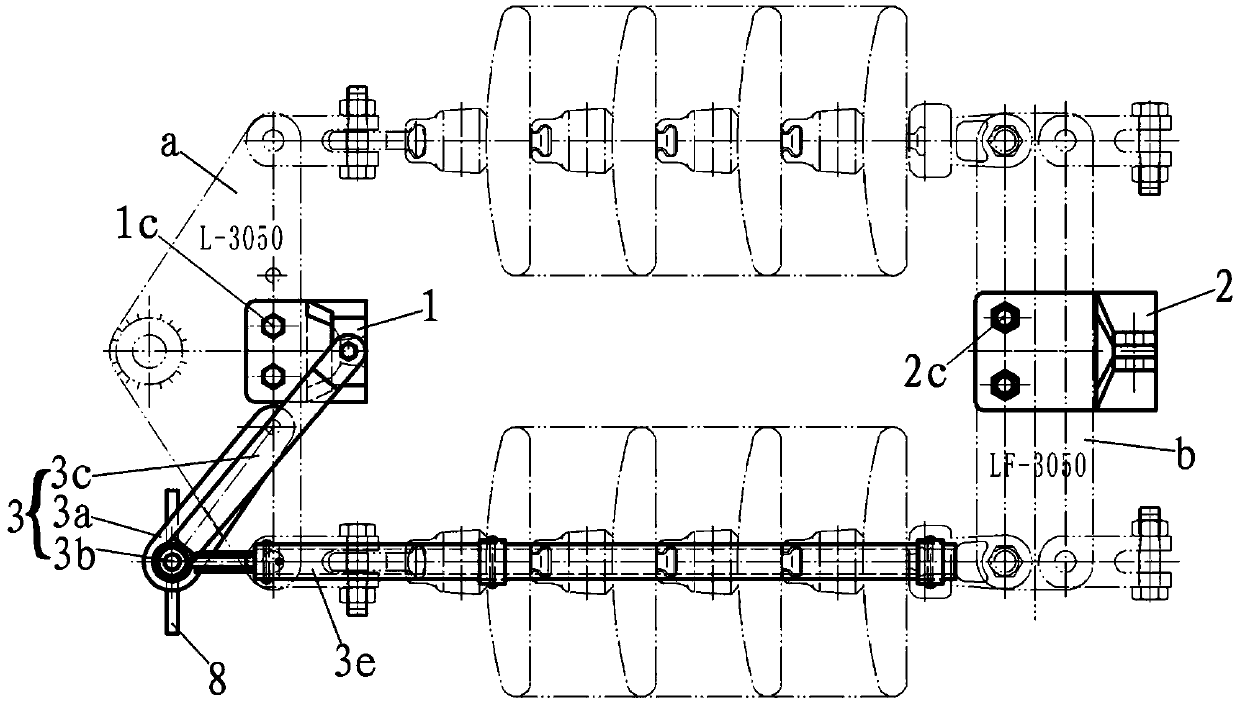

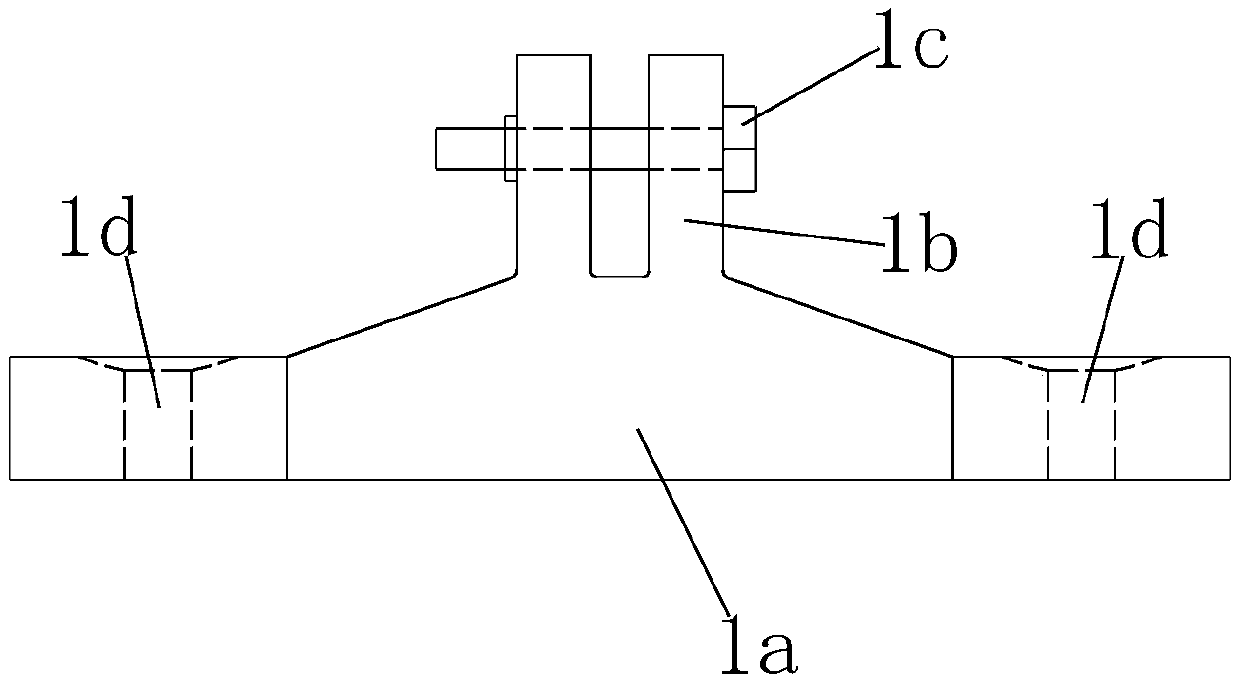

[0058] Such as figure 1 A combined tool for replacing the tension string of the DC grounding electrode line shown by a horizontal rotation method includes a cross-arm side-connection board 1 that can be fixedly clamped on the bottom edge of the cross-arm side triangular connection plate a, and can be fixedly clamped The wire side connecting board 2 and the rotating hanger assembly 3 on the wire side connecting board b; the cross-arm side connecting board 1 is vertically arranged with the cross-arm side triangle connecting board a, and the wire side connecting board 2. Arranged vertically with the wire side connection board b, the upper and lower ends of the cross arm side connection board 1 are respectively inserted with an upper anti-twist screw rod 4 and a lower anti-twist screw rod 5, and the upper anti-twist wire The rod 4 is connected to the upper end of the wire side connecting board 2 through the upper insulating rod 6, and the lower anti-twist screw rod 5 is connected ...

Embodiment 2

[0068] The method of using the combined tool for replacing the strain string of the DC grounding electrode line by the above-mentioned horizontal rotation method includes the following steps:

[0069]1) The ground potential electrician climbs to the ground potential electrician's working position of the tower, and the ground potential electrician installs the tower fixed pulley on the tower and puts the tower side transfer rope on the tower fixed pulley;

[0070] 2) The first ground electrician transfers the insulating operating rod and the wire fixed pulley with the wire side transfer rope to the ground potential electrician through the transmission rope on the side of the tower, and the ground potential electrician hooks the fixed pulley on the wire through the insulating operating rod to correspond to the old wire. The position of the wire end of the tension string;

[0071] 3) The second ground electrician secures the end of the insulating ladder with the transfer rope on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com