Device and method for testing performance of thermoelectric device

A thermoelectric device and performance technology, applied in the direction of measuring devices, measuring device casings, electrical measuring instrument components, etc., can solve the problem of lack of testing equipment and facilities for micro-thermoelectric refrigeration devices, and achieve the effect of meeting high power density

Pending Publication Date: 2022-03-15

辽宁冷芯半导体科技有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

An important difficulty restricting domestic research on micro-thermoelectric refrigeration devices is the lack of corresponding testing equipment and facilities for simulating the actual application environment.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0043] Example 1 Test the cooling and temperature control performance of the TEM-030410-01M micro-device under vacuum, 0.1W load, and 25°C

[0044] Such as figure 1 The apparatus used for the test is as described above.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

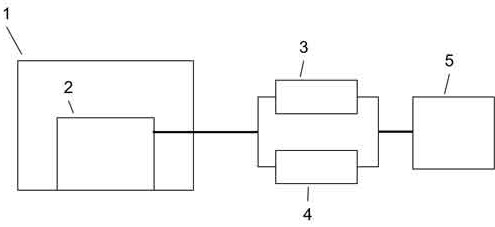

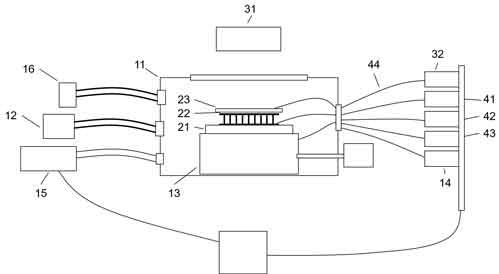

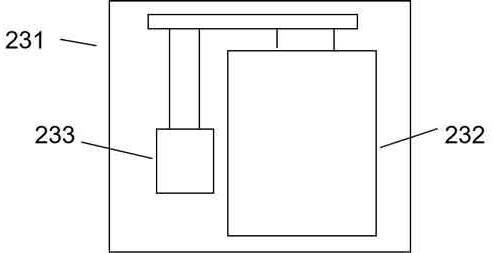

The invention relates to the field of thermoelectric device performance testing of semiconductor devices, in particular to a device and method for testing the performance of a thermoelectric device. The device comprises a test environment manufacturing system, a pluggable sample table, a temperature detection system, an electric signal detection system and automatic test software. The test environment manufacturing system creates a high-vacuum constant-temperature test environment for the to-be-tested sample; the plug-in sample table is used for fixing a device to be tested, realizes good thermal contact and electric contact with the device, and is mounted in the test environment manufacturing system; a probe of the temperature detection system is fixed on the plug-in sample table and the thermoelectric device and is used for monitoring the temperature change of the upper surface of the thermoelectric device; the electric signal detection system is connected with the thermoelectric device and the load and used for detecting related electric signals of the device. And the automatic test software is connected with the test environment manufacturing system, the temperature detection system and the electric signal detection system to realize automatic test of the device. According to the invention, a plurality of parameters of refrigeration and power generation performance of the thermoelectric device can be tested and calculated, performance test with higher precision and larger temperature zone is realized by adopting a vacuum and liquid nitrogen / thermoelectric composite cold and hot table constant temperature method, and the method has wide application prospect.

Description

technical field [0001] The invention relates to the field of performance testing of thermoelectric devices of semiconductor devices, in particular to a device and method for testing the performance of thermoelectric devices. Background technique [0002] Among many new energy technologies, thermoelectric conversion technology has attracted much attention because it can use various waste heat in daily life to generate electricity. At the same time, the new generation of intelligent flexible micro-nano electronic systems represented by wearables and implants urgently needs to develop micro-milliwatt-level self-power supply technology, which can be combined with primary and secondary battery technology to improve the stability of device operation. and service life. Among them, thermoelectric material devices can use the temperature difference between human body temperature and surrounding environment to generate electricity, and become an effective solution for self-power supp...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01R31/26G01R31/00G01R1/04

CPCG01R31/2601G01R31/00G01R1/0408

Inventor 王春雨赵洋孙东明成会明其他发明人请求不公开姓名

Owner 辽宁冷芯半导体科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com