Device and method for testing performance of thermoelectric power generation chip

A technology of thermoelectric power generation and chip performance, which is applied in the direction of measuring devices, measuring device casings, measuring electricity, etc., and can solve problems such as small battery capacity, inability to meet continuous power supply, and short battery life

Pending Publication Date: 2022-03-11

辽宁冷芯半导体科技有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The primary and secondary batteries currently used generally have small battery capacity, short battery life, and cannot meet the needs of continuous power supply.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0037] Example 1 Test the power generation performance of the model TEM-10010008-01M micro-device under vacuum, forced heat dissipation, temperature difference 10K, plane heat source and load 3Ω

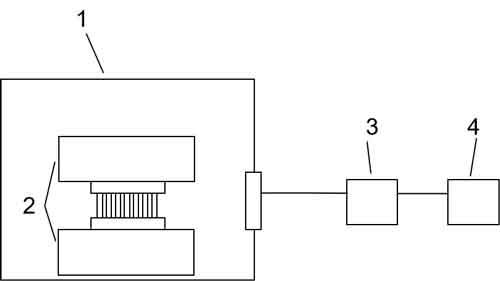

[0038] Such as figure 1 The apparatus used for the test is as described above.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

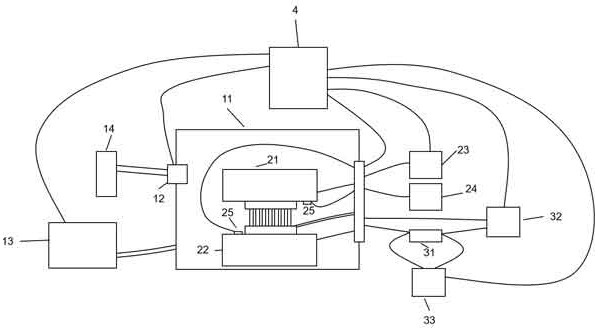

The invention relates to the field of semiconductor device performance testing, in particular to a device and method for testing the performance of a thermoelectric power generation chip. The device comprises an atmosphere environment control module, a temperature environment control module, an electric signal control and test module and automatic test software. The atmosphere environment control module creates testing environments of different atmosphere environments for a sample to be tested, and the testing environments specifically comprise a vacuum environment, an inert gas environment, an air environment and a low-pressure environment; the temperature environment control module provides a temperature difference environment required by thermoelectric power generation for the to-be-tested sample; the electric signal control and test module provides an external load circuit for the to-be-tested sample and detects voltage and current signals of the circuit. The automatic test software is respectively connected with the atmosphere environment control module, the temperature environment control module and the electric signal control and test module, can provide different test atmospheres, temperature differences and load circuit environments for the to-be-tested sample through centralized control, and detects and obtains data. According to the invention, multiple parameters of the performance of the thermoelectric power generation chip can be tested and calculated, the power generation performance detection of the chip in different temperature difference environments is realized by replacing a heater and a radiator assembly of the temperature environment control module, the scene of a product in practical application is simulated, and the test efficiency is improved. And the research on the thermoelectric power generation chip is promoted.

Description

technical field [0001] The invention relates to the field of semiconductor devices, in particular to a device and method for testing the performance of a thermoelectric power generation chip. Background technique [0002] Among many new energy technologies, thermoelectric conversion technology has attracted much attention because it can directly use various waste heat in daily life to generate electricity to realize the secondary utilization of energy, and has no secondary pollution to the environment. The low utilization rate of industrial waste heat is an important reason for high energy consumption. The waste heat and energy of major industries in my country account for ~20% of the total industrial energy consumption. The utilization of high-temperature waste heat is relatively good at home and abroad, but there is no good utilization technology for medium-low temperature (below 300 °C) waste heat; centralized waste heat utilization is better, but there is no good utiliza...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01R31/28G01R31/26G01R1/04

CPCG01R31/2856G01R31/26G01R1/0425

Inventor 邰凯平赵洋孙东明成会明

Owner 辽宁冷芯半导体科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com