Totally-worry-free lightning arrester

A lightning arrester and lightning arrester technology, applied in the field of lightning arresters, can solve problems such as thermal collapse and aging of zinc oxide arresters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

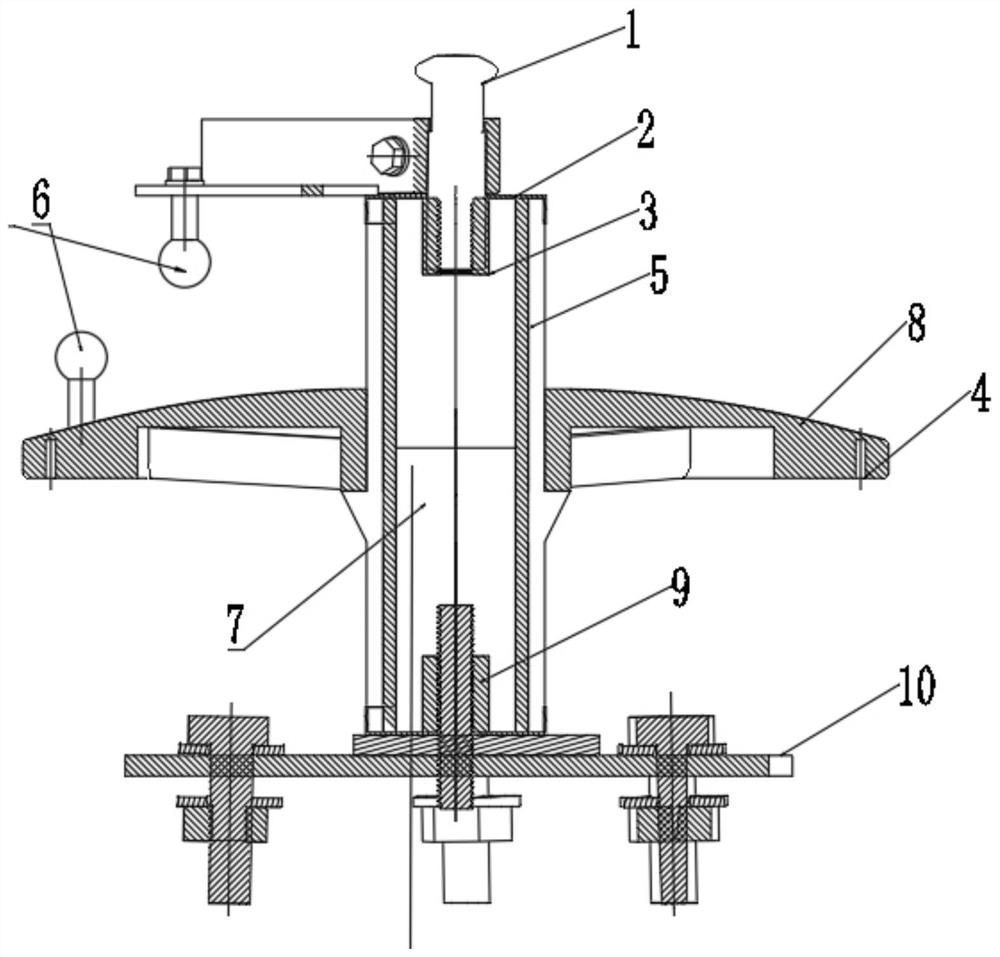

[0031] see figure 1 and 3 As shown, the worry-free lightning protection device includes 10kV worry-free surge arrester, and the 10kV worry-free surge arrester includes upper terminal 1, upper sealant 2, aluminum terminal seat 3, multi-cavity system 4, heat-shrinkable sealing tube 5, electrodes 6. Zinc oxide valve piece 7, synthetic sheath 8, lower terminal block 9, base 10; a single zinc oxide valve piece 7 is arranged in the heat-shrinkable sealing tube 5, and the top of the zinc oxide valve piece 7 passes through the aluminum terminal base 3 and the The upper terminal 1 is connected, and the upper sealant 2 is provided at the connection between the upper terminal 1 and the heat-shrinkable sealing tube 5. A connecting plate is installed on the connecting terminal 1, an electrode 6 is installed on the end of the connecting plate away from the upper connecting terminal, the bottom end of the zinc oxide valve plate 7 is connected with the lower connecting terminal 9, and the bo...

Embodiment 2

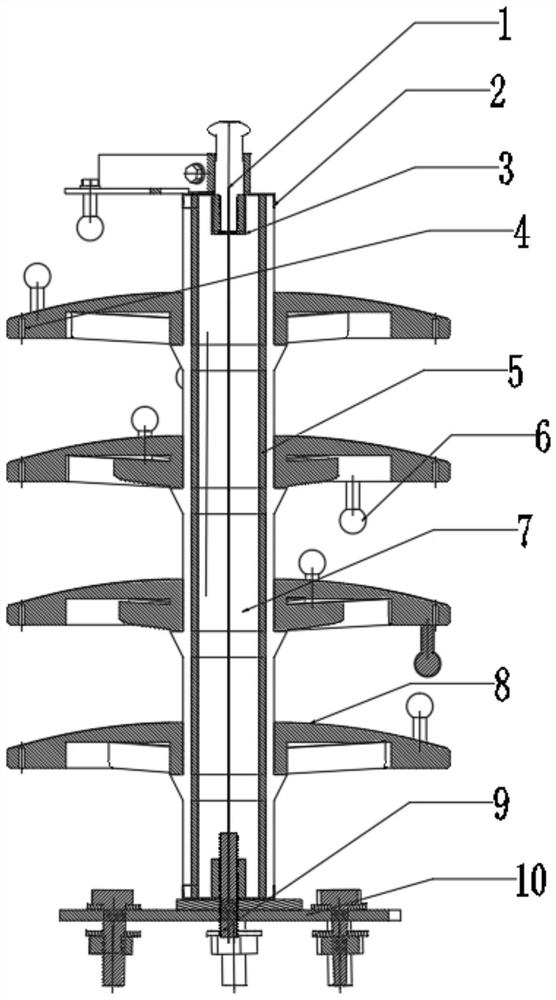

[0035] see figure 2 As shown, the 35kV worry-free lightning protection device is different from the 10kV worry-free lightning protection device in that: the heat-shrinkable sealing tube 5 of the surge arrester containing multiple sets of zinc oxide valve plates 7 is provided with a plurality of zinc oxide at equal intervals The valve plate 7, the outer wall of the heat-shrinkable sealing tube 5 of the surge arrester of multiple groups of zinc oxide valve plates 7 is provided with a plurality of synthetic sheaths 8, and the synthetic sheaths 8 at both ends are provided with a single electrode 6, and the multiple electrodes 6 in the middle A synthetic sheath 8 is provided with two electrodes 6, and the two electrodes 6 are respectively located on the upper and lower sides of the synthetic sheath 8;

[0036]Both the lightning arresters of Embodiment 1 and Embodiment 2 have two ways of lightning discharge. One is a multi-cavity system using "Simple Arc Quenching Technology". As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com