Outdoor compound insulation high-voltage anti-thunder support

A composite insulation and high-voltage technology, applied in the direction of insulators, supporting insulators, electrical components, etc., can solve the problems of unfavorable lightning protection function, increase the occupied area, insufficient safety distance, etc., achieve good lightning protection effect, save site space, and electric field evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

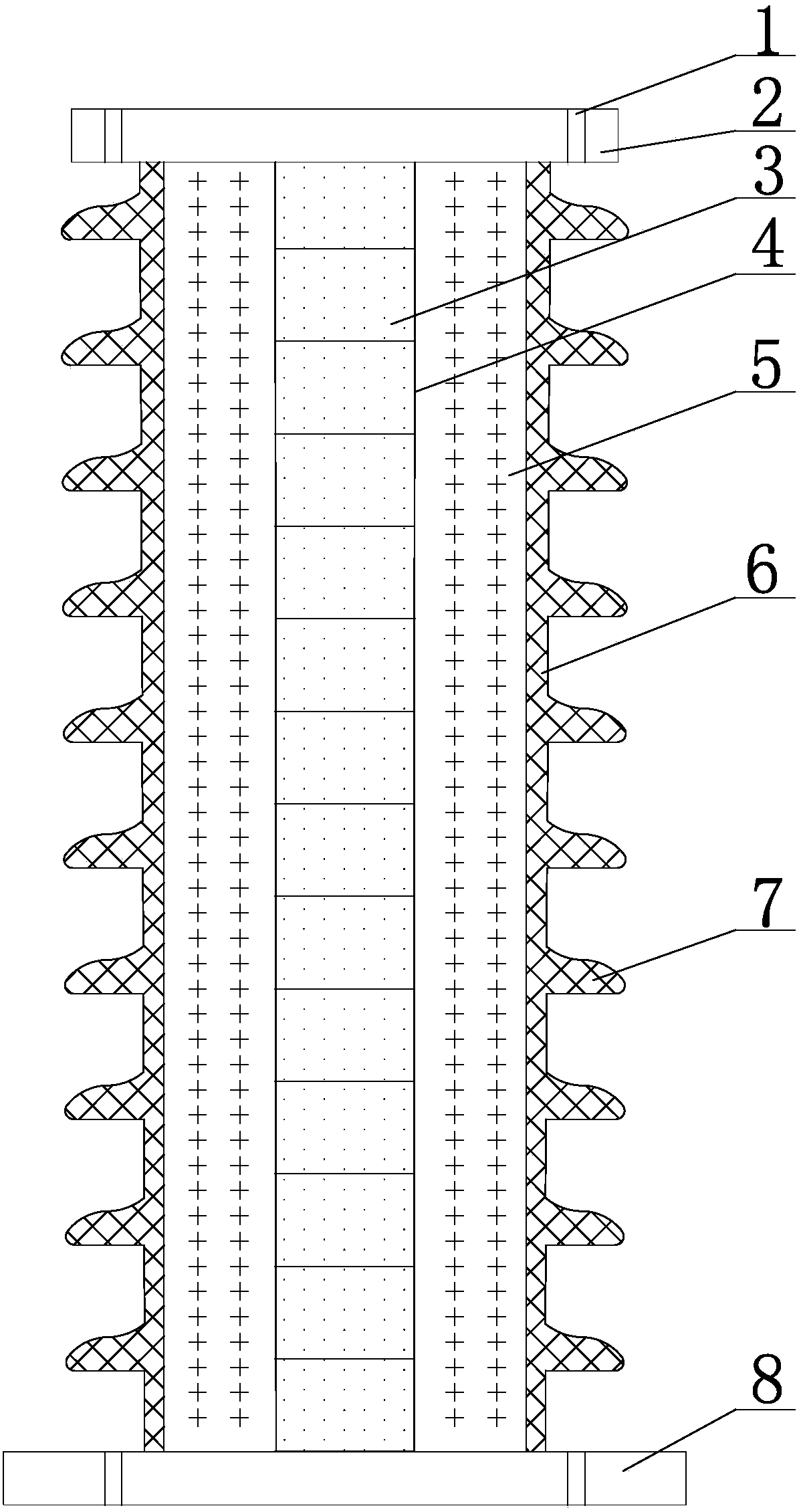

[0020] Such as figure 1 As shown, the outdoor composite insulating high-voltage lightning protection pillar of the present invention includes an insulating tube 5, the insulating tube 5 is a high-strength epoxy resin insulating tube or a glass fiber reinforced plastic insulating tube, the insulating tube 5 is a hollow ring structure, and the thickness of the tube wall is uniform. The length of the tube body and the electrical insulation level of 5 can withstand the normal operating voltage and various overvoltages of the corresponding voltage level. Compared with the cylindrical structure of the same quality, the mechanical strength and electrical insulation performance of the hollow ring structure have obvious advantages; The interior of the metal oxide valve plate 3 is filled with a metal oxide valve plate set 3, which is cylindrical and is formed by stacking a plurality of metal oxide valve plates 4. The cylindrical metal oxide valve plate 4 on the upper end is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com