Energy-saving efficient scrap steel crushing device

A crushing device and scrap steel technology, applied in the direction of solid waste removal, presses, stamping machines, etc., can solve the problems of increasing crushing time, scrap iron extrusion processing operation, post-shadow crushing operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

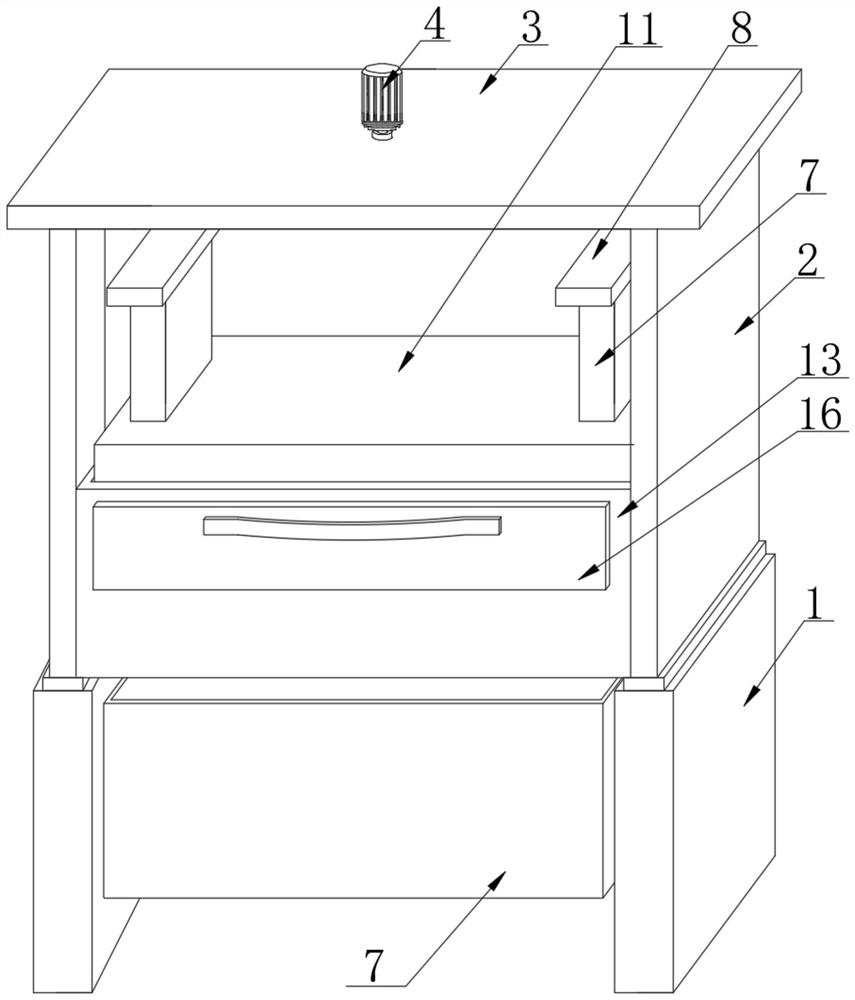

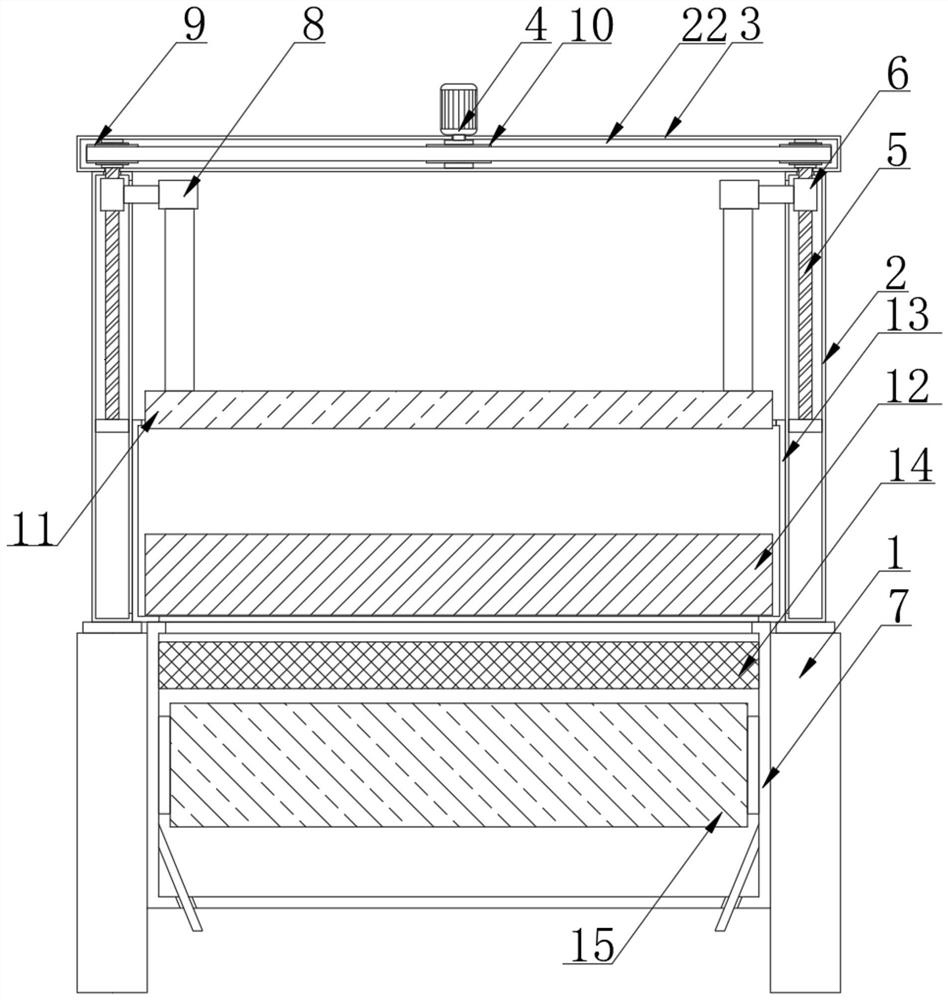

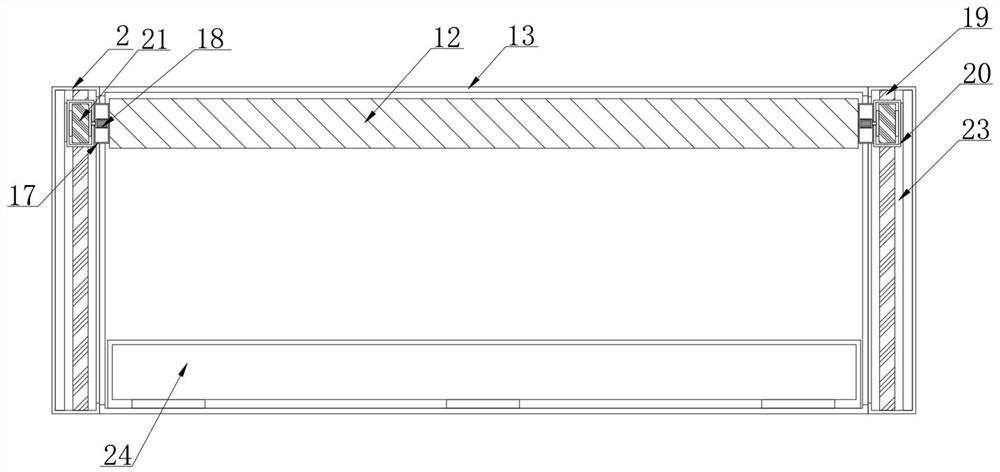

[0024] see Figure 1-5 , this embodiment provides an energy-saving and high-efficiency scrap steel crushing device, comprising two support columns 1, a crushing box 7 is fixedly connected between the two support columns 1, and two crushing rollers are symmetrically arranged inside the crushing box 7 15, the inside of one of the support columns 1 is provided with a rotating mechanism 31, the tops of the two support columns 1 are fixedly connected with a support plate 2, and the two support plates 2 are fixedly connected with a processing box 13, and the inside of the processing box 13 is equipped with Pushing plate 12 is arranged, and the inside of two supporting plates 2 is provided with pushing mechanism 23, and the top of two supporting plates 2 is fixedly connected with top plate 3, and the inside of top plate 3 is provided with lifting mechanism 22.

[0025] Most of the existing crushing devices directly crush the steel scrap, but because the shape and volume of the steel ...

Embodiment 2

[0033] see figure 1 , further improvements have been made on the basis of Example 1:

[0034] In order to facilitate the feeding of scrap steel and push the extruded scrap steel into the crushing box 7, a discharge opening is dug on the bottom end surface of the side away from the pushing plate 12 in the processing box 13, and the inside of the discharge opening Rotation is connected with electric door 24, and the side wall of processing case 13 is dug to be provided with feeding chute, and the inside of feeding chute is provided with sealing plate 16, and sealing plate 16 is rotatably connected in the feeding chute.

[0035] In this embodiment, by opening the sealing plate 16 on the treatment box 13, steel scrap can be dropped from here on the treatment box 13 to achieve the effect of feeding. After the feeding is completed, close the sealing plate 16. After the pressing is completed, by opening the electric door 24, the scrap steel can be facilitated by the pushing plate 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com