Environment-friendly soil sterilization treatment equipment in field of agricultural engineering

A technology for agricultural engineering and soil sterilization, applied in the field of agricultural engineering, can solve the problems of the efficiency of sterilization and the inability to be directly irradiated, and achieve the effect of reducing energy consumption and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

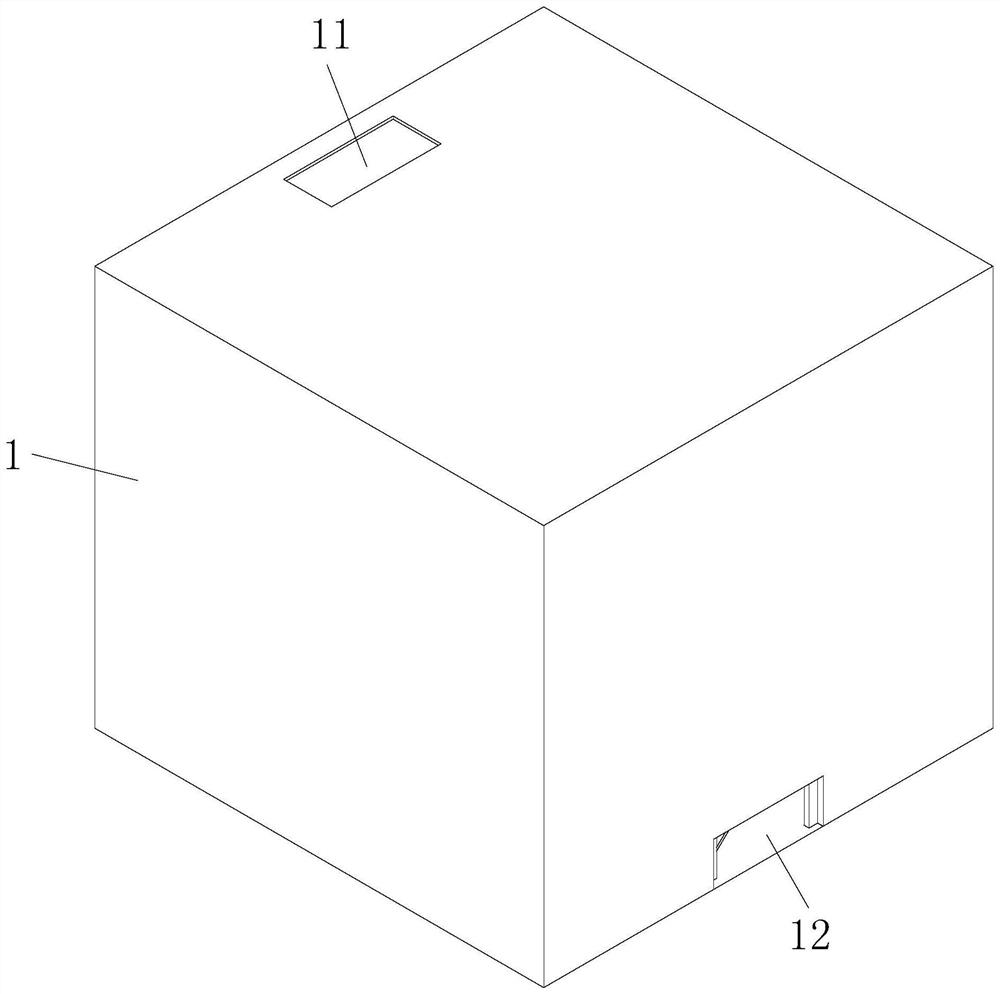

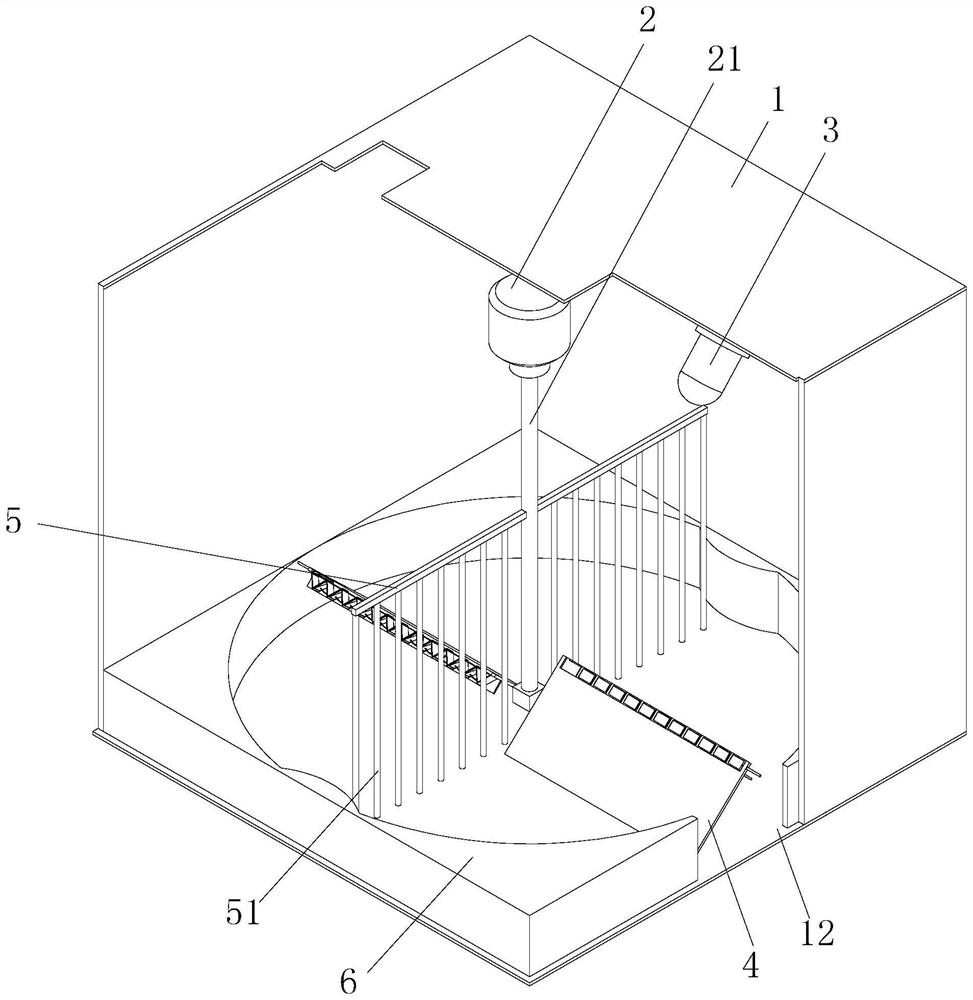

[0030] see Figure 1-2 , the present invention provides a technical solution: an environmentally friendly soil sterilization treatment equipment in the field of agricultural engineering, comprising an equipment main body 1, the top and right side of the equipment main body 1 are respectively provided with a feeding port 11 and a discharging port 12, and the main body of the equipment is provided with a feeding port 11 and a discharging port 12 respectively. 1 The top and rear side of the inner wall are respectively fixed with the drive motor 2 and the UV lamp head 3, the output shaft of the drive motor 2 is fixed with the rotating shaft 21, the bottom end of the rotating shaft 21 and the bottom of the inner wall of the main body 1 of the device are provided with a gap, and the bottom side of the rotating shaft 21 is fixed with a Two symmetrically arranged inclined turning blades 4, when the driving motor 2 drives the rotating shaft 21 to rotate, the upper surface of the incline...

Embodiment 2

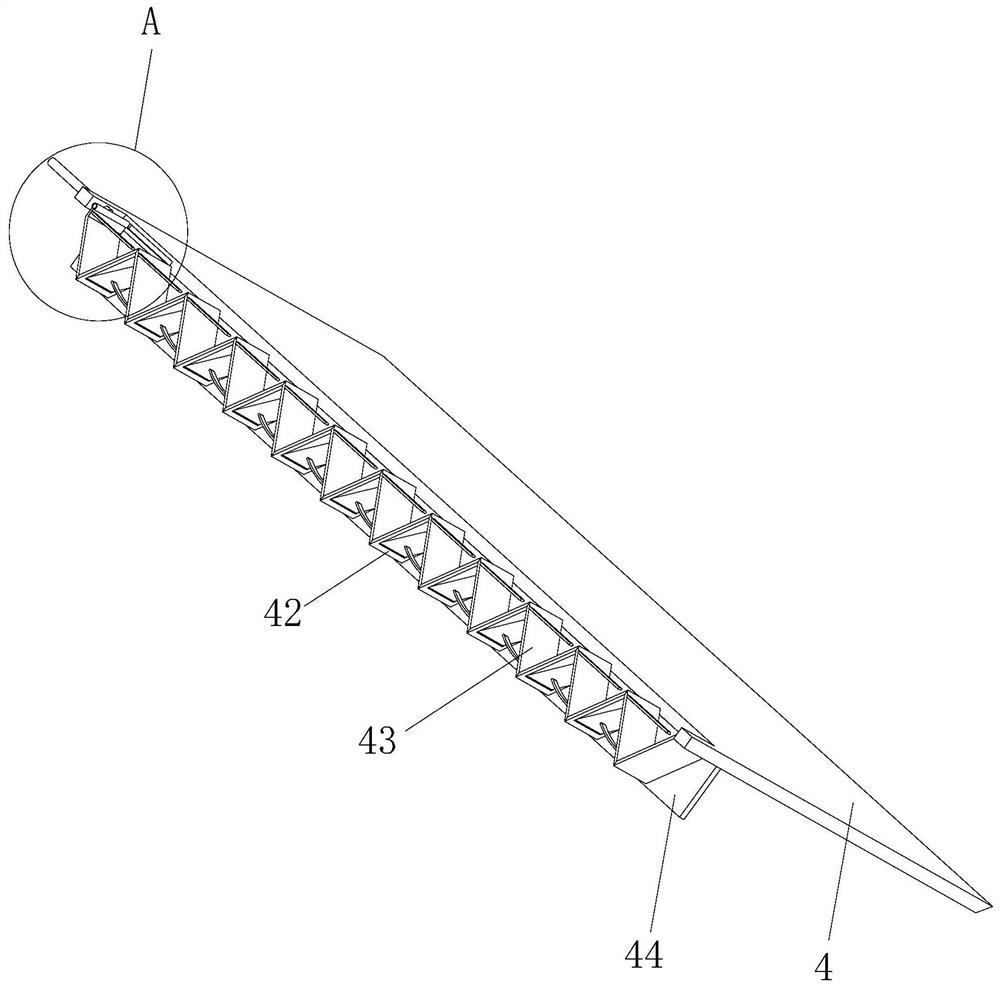

[0033] see Figure 3-4, On the basis of Embodiment 1, in this embodiment, a notch 41 is provided at the top of the inclined turning blade 4, and a plurality of groups of elastic filter meshes 42 and 43 fixed to each other are arranged inside the notch 41. The first filter screen 42 and the second elastic filter screen 43 are arranged in a "V" shape, and the bottoms of the elastic filter screen one 42 and the elastic filter screen two 43 are in contact with the support plate 44, and the support plate 44 is fixed on the inclined turning blade 4. The free end of the elastic filter screen-42 with the largest distance from the bottom end of the rotating shaft 21 is fixed with an active push bar 45, and the active push bar 45 runs through the side of the inclined turning blade 4 away from the rotating shaft 21 and is movably connected with the inclined turning blade 4, and the closed enclosure is closed. The inner sides of the front and rear parts of the baffle 6 are provided with a...

Embodiment 3

[0037] see Figure 3-5 , On the basis of Embodiment 2, in this embodiment, a through port is opened at the center of the second elastic filter screen 43, the interior of the through port is hinged with one end of the reinforcing block 7, and a torsion spring is provided at the connection between the reinforcing block 7 and the interior of the port. And both ends of the reinforcing block 7 are in contact with the inner wall of the opening, the side of the reinforcing block 7 away from the elastic filter net one 42 is in contact with one end of the reinforcing push bar 8, and the other end of the reinforcing push bar 8 is in contact with another group of elastic filter nets one 42 and 8. The first elastic filter 42 in the second elastic filter 43 is fixed. By setting the reinforcing push bar 8, the distance between the first elastic filter 42 and the second elastic filter 43 can be used to make the reinforcing block 7 rotate. The soil between them has the effect of squeezing, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com