An improved horizontal wheat threshing machine and its application method

An improved wheat threshing machine technology, applied in application, grain finishing, grain degerming, etc., can solve the problems of production environment pollution and inability to remove dust, and achieve good dust removal, safe and reliable production environment, and high practical value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

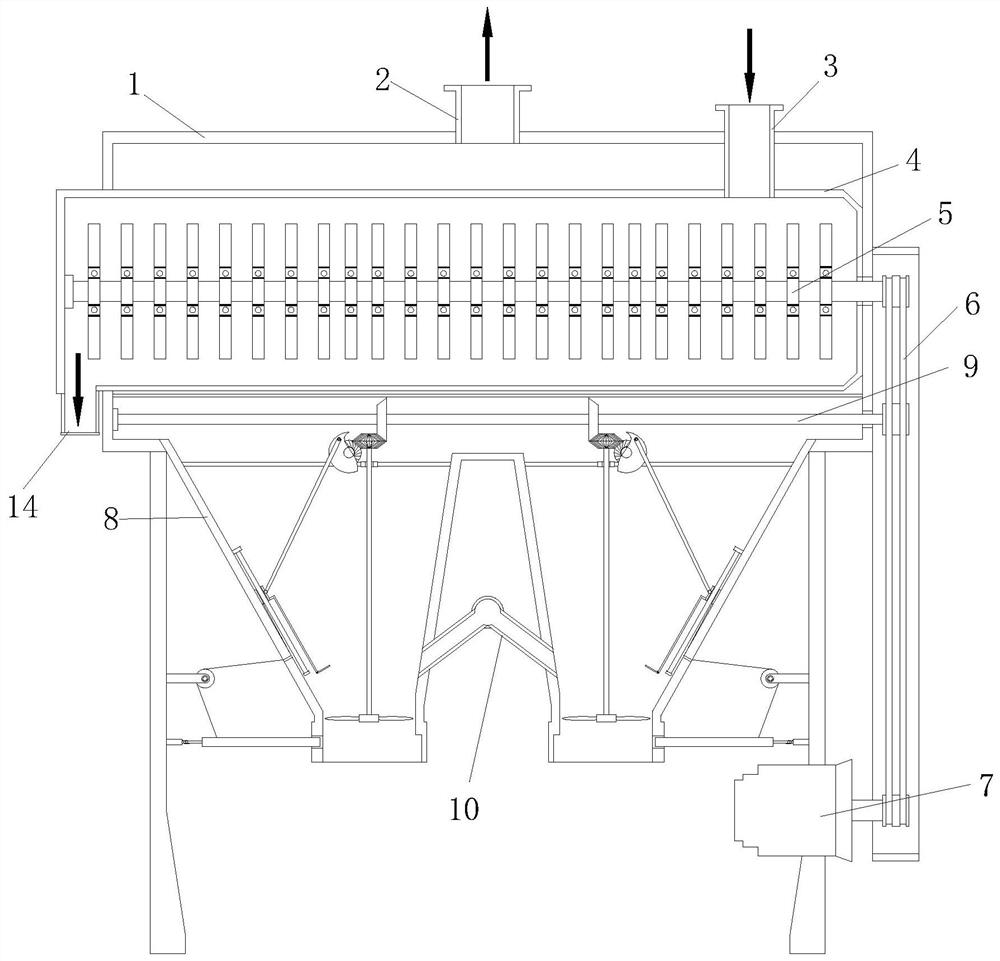

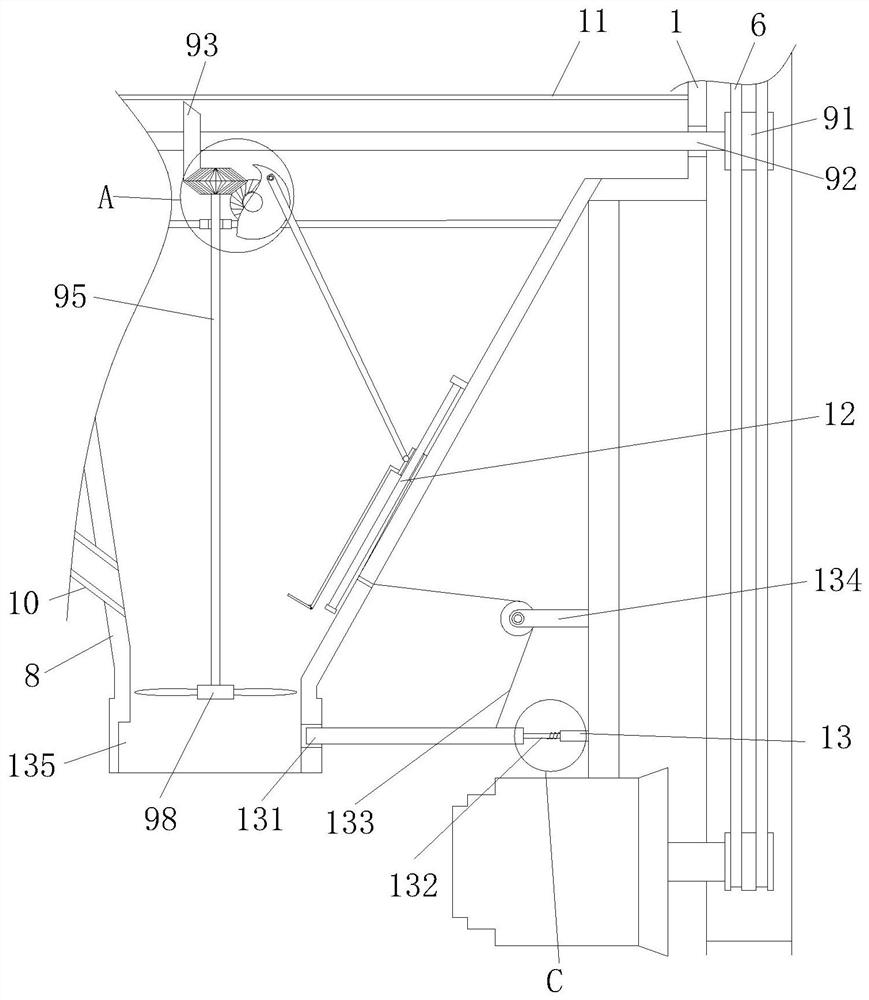

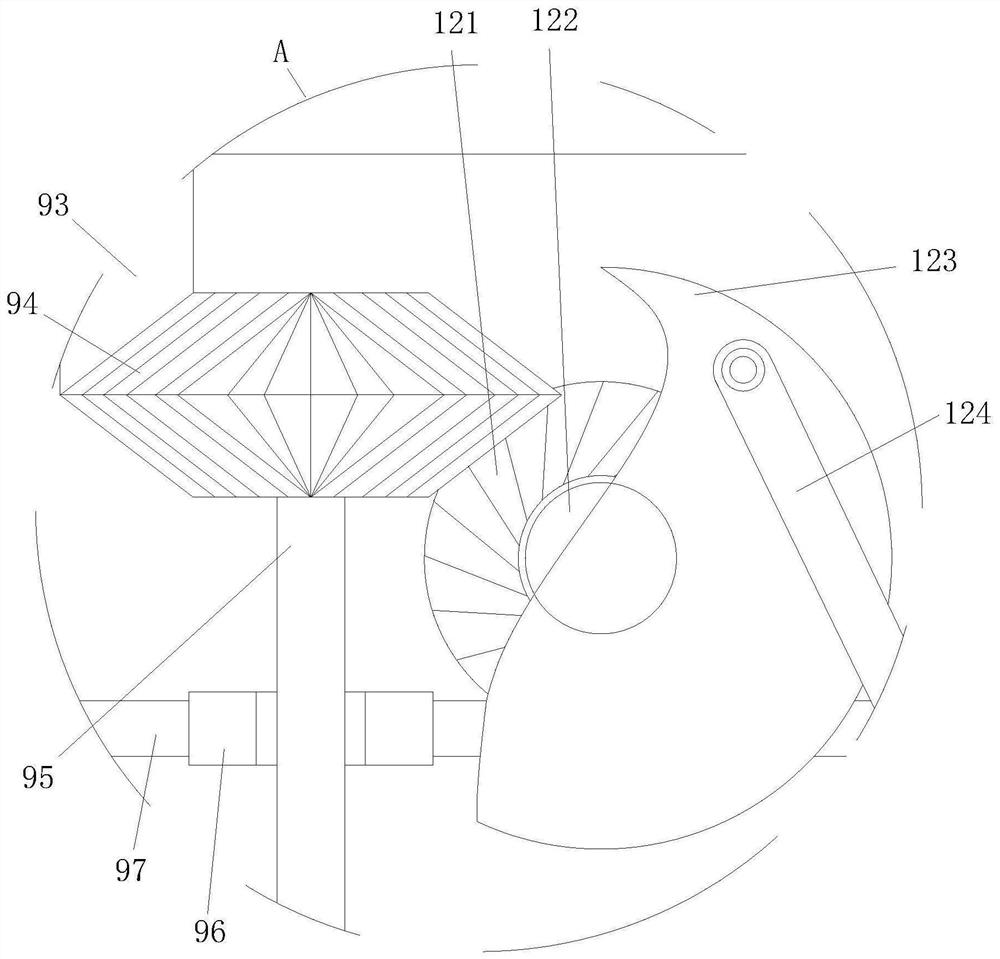

[0037] Attached below Figure 1-7 The present invention is further described with examples:

[0038] An improved horizontal threshing machine comprises a driving belt 6 of a threshing machine shell 1, a drive motor 7 and a granular impurity collecting pipe 8, and the granular impurity collecting pipe 8 is arranged on the bottom plate of the threshing machine shell 1, And the masher housing 1 is provided with a drive motor 7, the drive end of the drive motor 7 is connected with a transmission belt 6, the masher housing 1 is provided with a stirring mechanism 9, and the stirring mechanism 9 is connected with the transmission belt 6, The transmission belt 6 is also connected to the beating plate 5, and the beating plate 5 is arranged in the sieve cylinder 4, and the sieve cylinder 4 is provided with a feeding pipe 3 and a discharging pipe 14. A suction pipe 2 is provided, and the suction pipe 2 is connected with the external air extractor. In the present invention, by improving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com