Mechanical linkage mechanism

A linkage mechanism and mechanical technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of reducing production efficiency, waste of resources, affecting the quality of metal pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

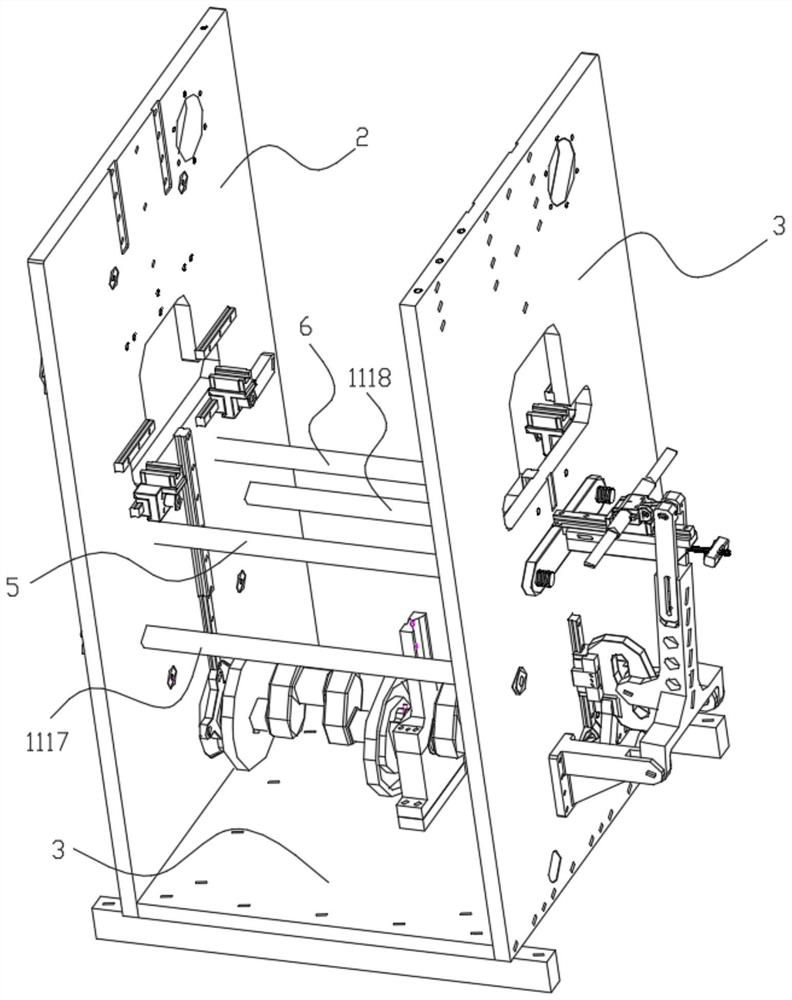

[0130] It should be noted that the mechanical linkage mechanism described in the present invention realizes that the transmission mechanisms with different functions can work together and simultaneously through the cooperation between pure bearings and connecting rods. In order to make the present invention easier to understand, the following will be combined with the production process of the tank body as a reference description, as follows:

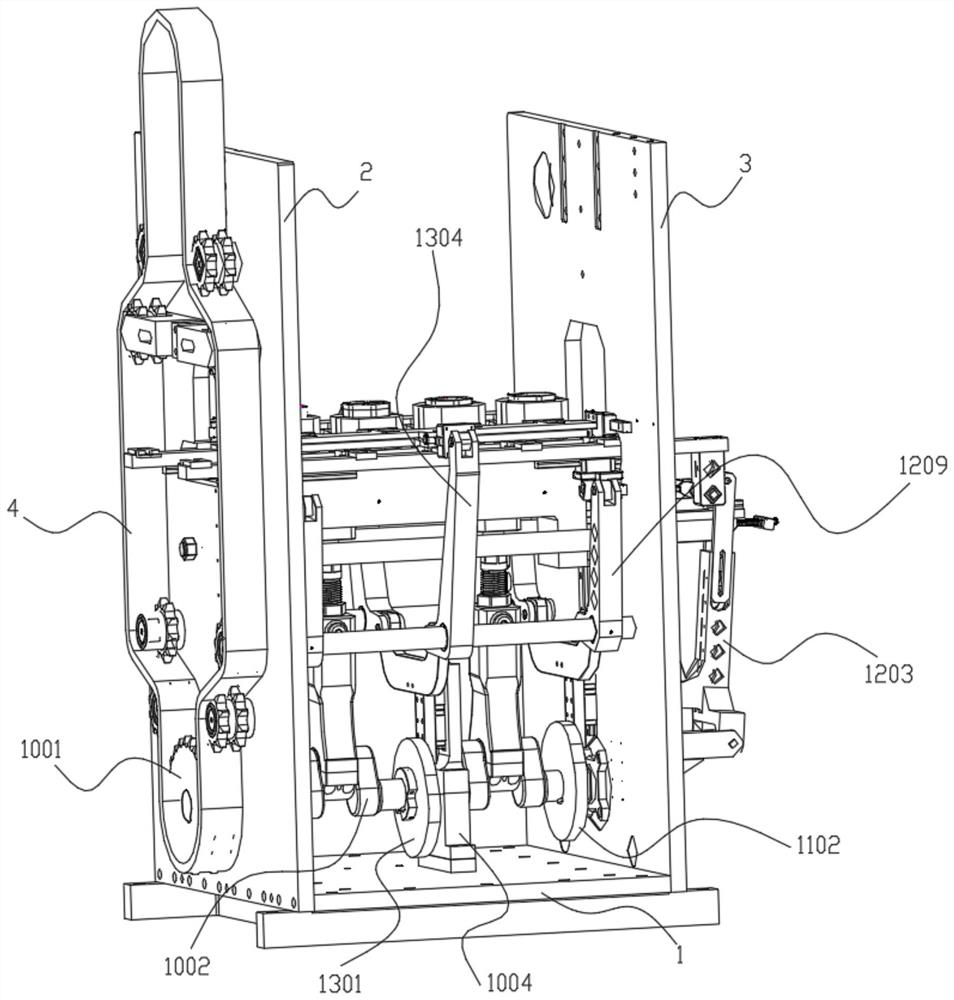

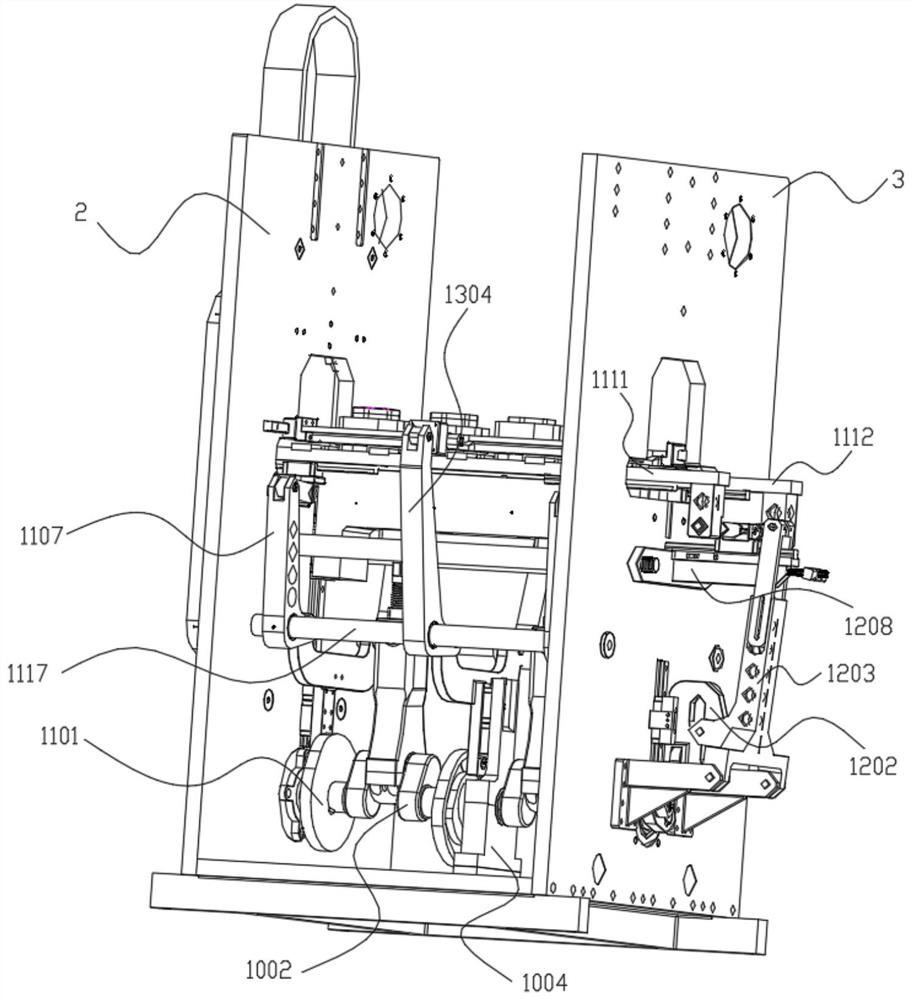

[0131] Such as figure 1 - Figure 8 As shown, a mechanical linkage mechanism includes:

[0132] The main transmission mechanism 10 is used to output driving force for the linkage of the mechanical linkage mechanism;

[0133] The first auxiliary transmission mechanism 11 is used to realize the first auxiliary transmission according to the driving force provided by the main transmission mechanism 10; the first auxiliary transmission mechanism 11 is mainly used to realize the clamping of the target object (this paper takes a tank as an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com