A kind of three anti-chenille jacquard curtain fabric production line and production method

A production line and fabric technology, applied in the processing of textile materials, processing of textile material carriers, continuous processing of textile materials, etc., can solve the problems of low efficiency of slurry block removal, lack of protection of fabrics, and difficult removal of slurry blocks, etc., to achieve improved Emulsification efficiency, enhanced emulsification penetration, enhanced emulsification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

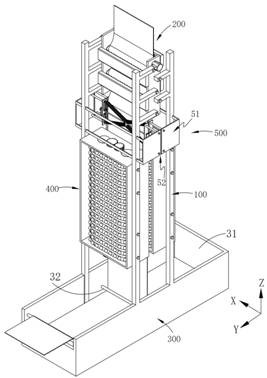

[0049] like figure 1 Shown, a kind of three anti-chenille jacquard curtain fabric production line, comprises:

[0050] Rack 100;

[0051] The infiltration part 200, the infiltration part 200 is arranged on the top of the frame 100;

[0052] A padding section 300, the padding section 300 is arranged at the bottom of the frame 100;

[0053] Pushing and rubbing part 400, said pushing and rubbing part 400 is arranged between said pushing and infiltrating part 200 and padding and rolling part 300; and

[0054] A finishing part 500, the finishing part 500 is installed between the push seepage part 200 and the push rub part 400;

[0055] The two sides of the fabric are conveyed vertically downward through the push-infiltration part, and 200 injections of the pushing agent are injected back and forth to infiltrate them. The finishing part 500 continuously outputs the fabric from the middle to the two sides and pulls and sorts it back and forth. Pushing and rubbing sideways in a re...

Embodiment 2

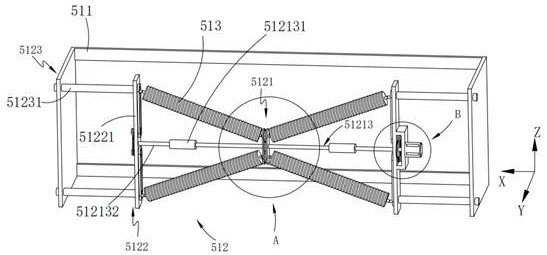

[0138] like figure 1 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that the sorting unit 500 includes:

[0139] Finishing components 51 arranged symmetrically on both sides of the fabric; and

[0140] The finishing channel 52 is formed between the finishing components 51 .

[0141] In this embodiment, the finishing assembly 51 pulls and sorts the fabric in the finishing channel 52 by rotating and pushing the fabric from the middle to the upper and lower sides. The rotation on both sides pushes the fabric to realize the finishing work of the fabric along the fabric conveying direction.

[0142] like figure 2 As shown, the finishing assembly 51 includes:

[0143] the second bas...

Embodiment 3

[0166] like Figure 14 Shown, a kind of production method of three anti-chenille jacquard curtain fabrics comprises the steps:

[0167] Step 1, cold pile treatment, after the fabric is treated with cold pile liquid, it is piled up;

[0168] Step 2: Pushing the agent, the fabric is conveyed vertically downward to the pushing part 200, the spraying part 21 evenly sprays the high-concentration refining agent solution on the fabric, and injects the agent back and forth through the injection pushing part 22 to penetrate both sides of the fabric;

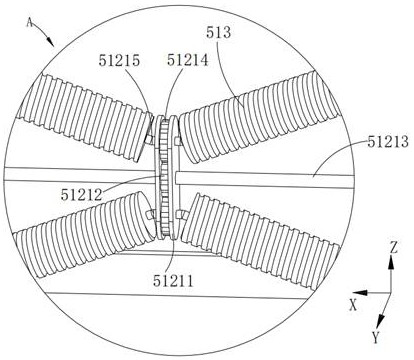

[0169] Step 3: finishing the fabric, the infiltrated fabric passes through the finishing part 500, and the screw 513 on the finishing assembly 51 rotates on the fabric, so that the fabric in the finishing channel 52 is pulled and sorted to both sides, and the screw 513 is transported along the fabric Direction pulls the fabric up and down synchronously, and makes the side of the screw 513 close to the edge of the fabric not contact the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com