UWB personnel wrist strap packaging equipment

A technology for packaging equipment and wristbands, which is applied in the field of UWB personnel wristband packaging equipment, can solve the problems of dust-proof glue waste, glue overflow, etc., and achieve the effects of saving use, reducing steps, and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

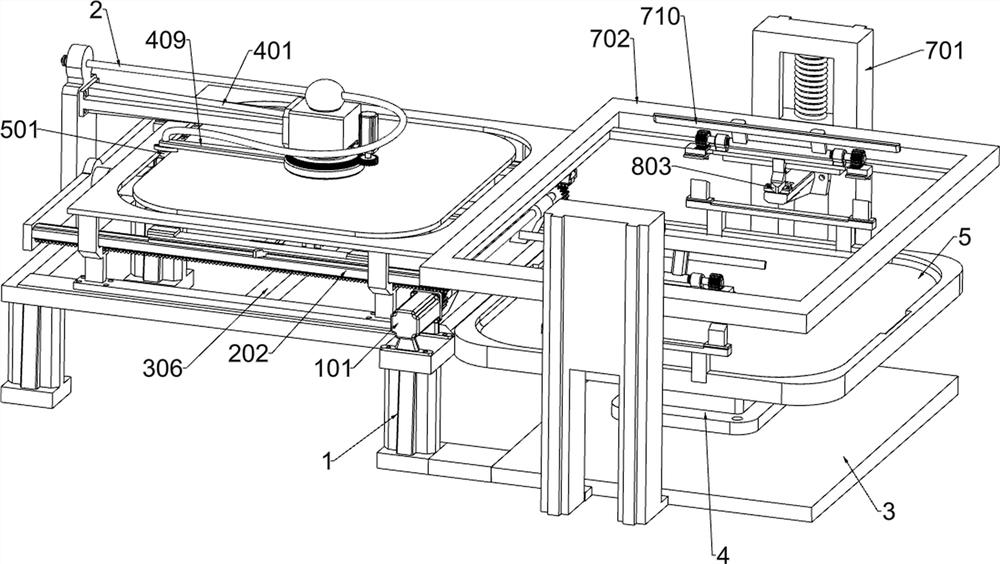

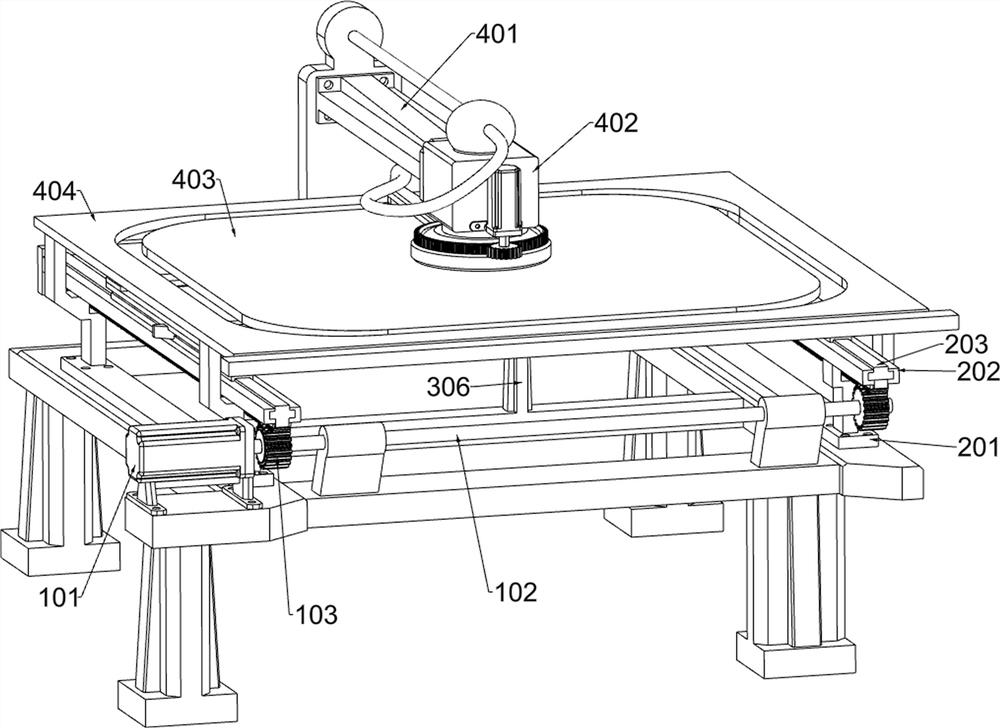

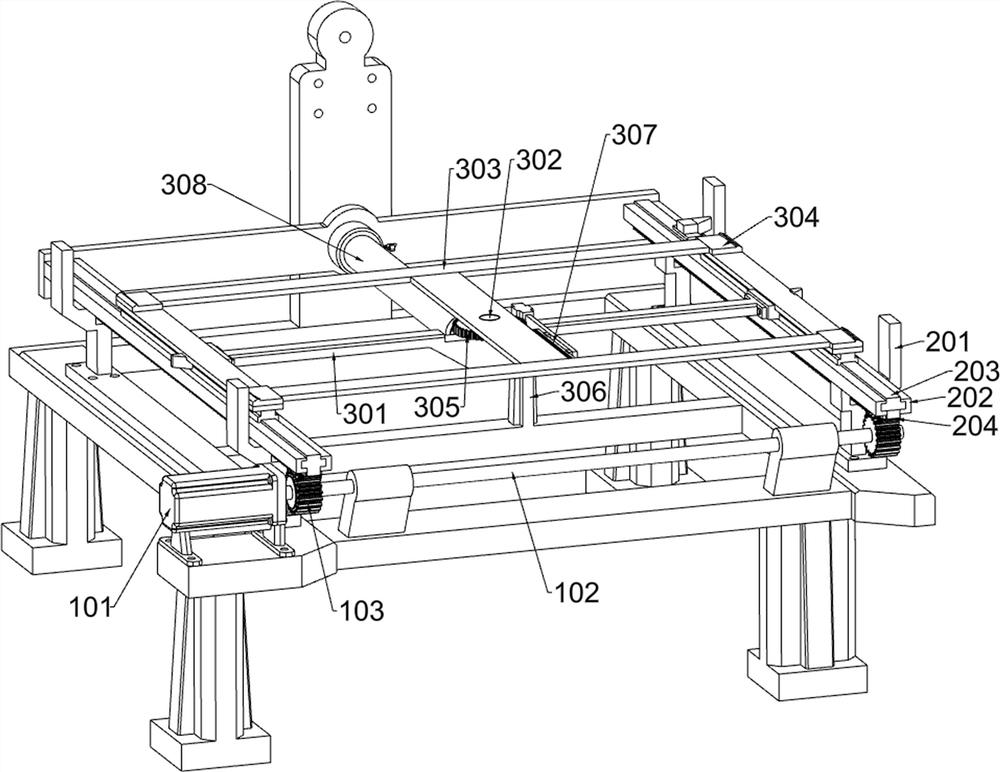

[0036] A device for UWB personnel wristband packaging, such as Figure 1-2 As shown, it includes active power assembly, lateral displacement assembly, rotation assembly, path control assembly, spraying assembly, support platform 1, rubber delivery pipe 2, chassis platform 3, electric lifter 4 and positioning plate 5; the right end of support platform 1 is fixed to There is an underframe 3; the upper bolt of the underframe 3 is connected with an electric elevator 4; the upper bolt of the electric elevator 4 is connected with a positioning plate 5; the right part of the bracket 1 is connected with a main power component; Displacement assembly; the right part of the lateral displacement assembly is engaged with the active power assembly; the inner side of the lateral displacement assembly is fixedly connected with the rotation assembly; the lower part of the rotation assembly is connected to the support platform 1; the upper bolt of the support platform 1 is connected with the pat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com