Rapid-steel-inlaid spiral cutter with good wear resistance

A technology of wear resistance and helical cutter, which is applied to the parts of boring machine/drilling machine, drilling/drilling equipment, drilling tool accessories, etc. It can solve the problems of increasing tool friction and tool damage, so as to increase friction and improve Wear resistance, good effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

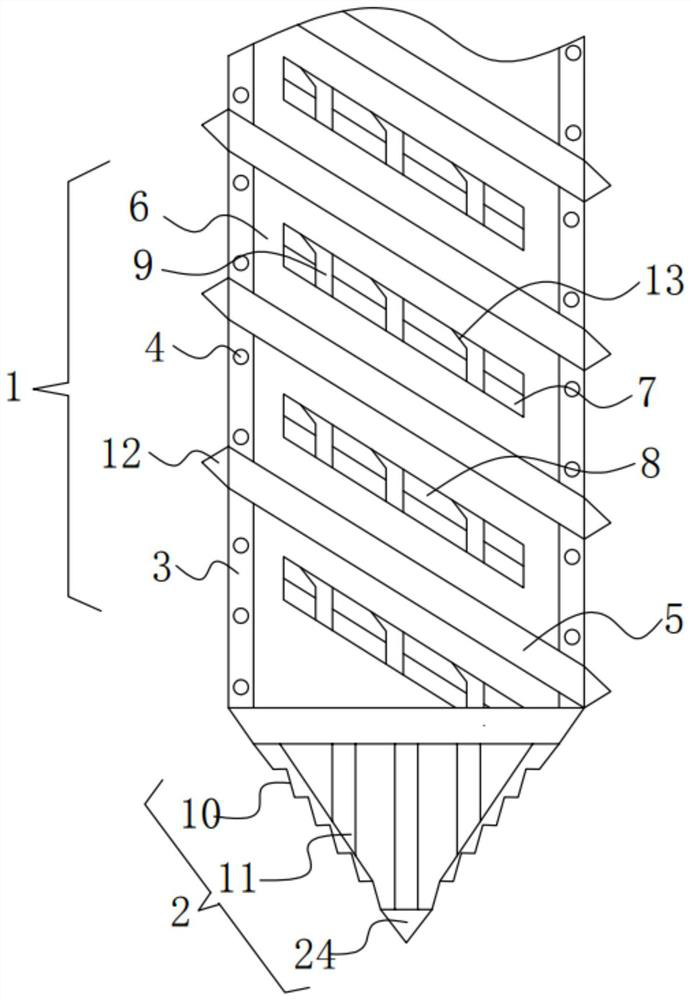

[0029] Please refer to figure 1 ,in, figure 1 It is a structural schematic diagram of the first embodiment of the inlaid steel spiral knife with good wear resistance provided by the present invention. The inlaid steel spiral cutter with good wear resistance includes a cutter head 1 and a screw rod 2, the outer surface of the screw rod 2 is provided with a reinforcing rib 3, and the inside of the reinforcing rib 3 is provided with a flow hole 4, and the The outer surface of the screw rod 2 is provided with helical teeth 5, and a chip removal channel 6 is opened between adjacent helical teeth 5, and the chip removal channel 6 is provided with a wear strip 7 for increasing the friction force of the helical teeth, so One side of the wear-resistant strip 7 is provided with a heat sink 8, and the heat sink 8 is provided with chip removal holes 9 for guiding;

[0030] Through the provided reinforcing rib 3, the overall strength of the threaded rod 2 can be increased to avoid deform...

no. 2 example

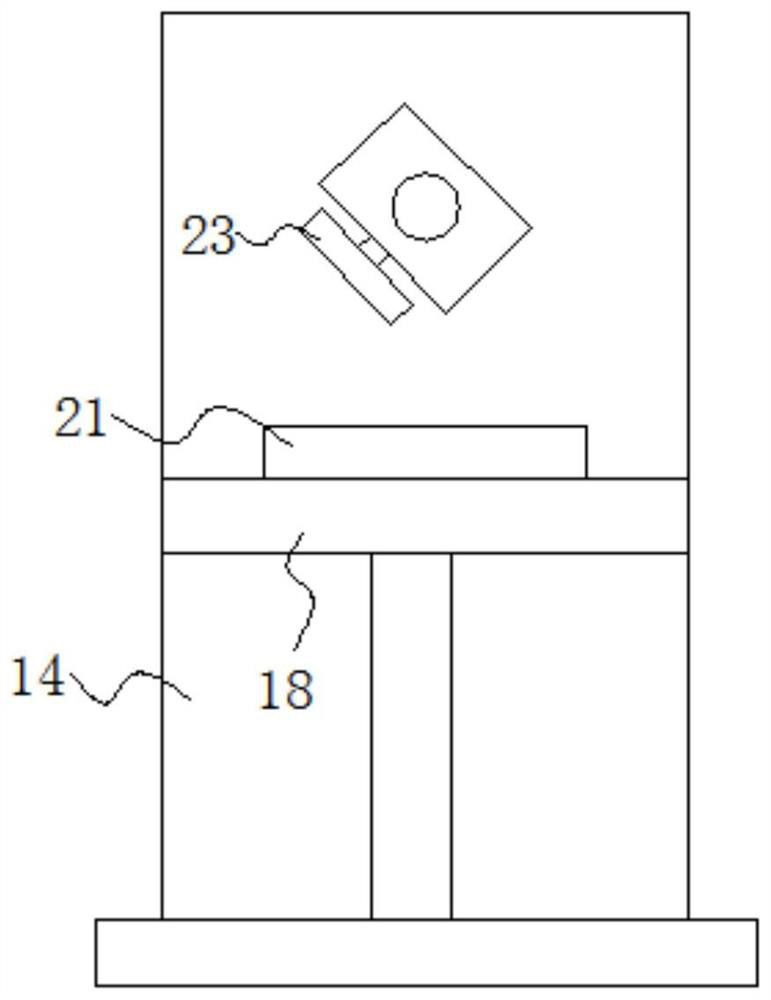

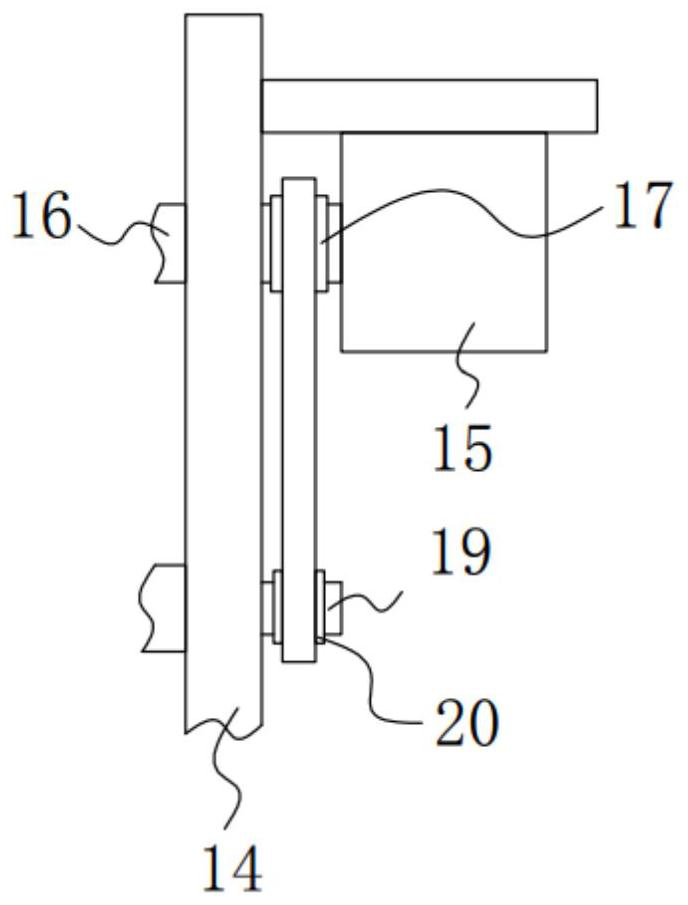

[0047] Please refer to Figure 2-4 , based on the inlaid steel helical knife with good wear resistance provided by the first embodiment of the present application, the second embodiment of the present application proposes another inlaid steel helical knife with good wear resistance. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0048] Specifically, the difference of the inlaid steel helical knife with good wear resistance provided by the second embodiment of the present application is that the production of the inlaid steel helical knife with good wear resistance includes the following steps:

[0049]S1. Raw material pretreatment: wet grinding, drying, and sieving the raw material mixture of the inlaid steel spiral knife, and then add a forming agent to mix;

[0050] S2. Raw material reprocessing: the material obtained in step S1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com