Water cooling system for cable protection pipe production

A cable protection tube and water-cooling system technology, which is applied in the direction of coating, etc., can solve the problems of low work efficiency, low water-cooling quality, and high labor intensity of operators, and achieve the effect of improving water-cooling efficiency and avoiding scatter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

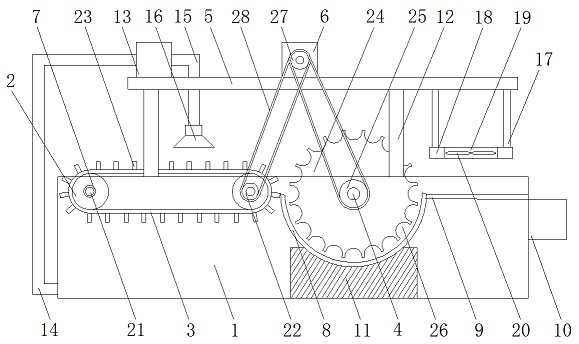

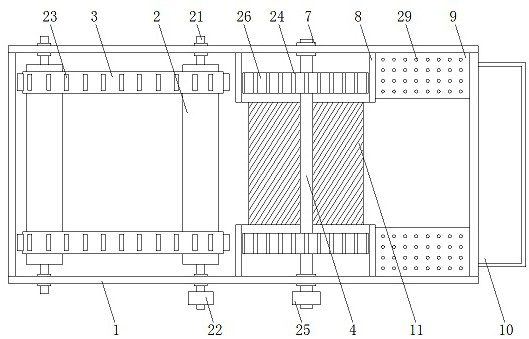

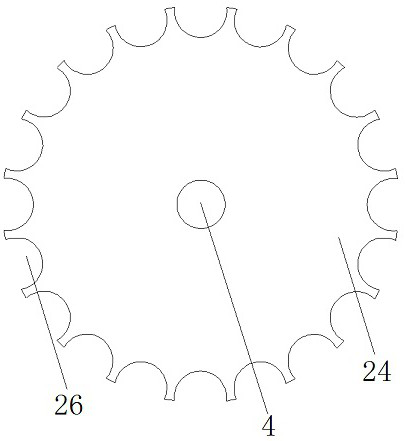

[0022] Append Figure 1-4 As shown, a cable protective tube is produced by water cooling system, including water tank 1, rotating roller 2, a transmission belt 3, a rotating shaft 4, a top plate 5, and a motor 6, characterized in that the water tank 1 is provided with bearing 7 The positioning groove 8 is provided on the inner wall of the water tank 1, and a fixing plate 9 is provided on the outer wall of the water tank 1, and a column 12 is provided at the top of the water tank 1, and the rotary roller 2 is provided with a connection. The shaft 21 is applied from the bearing 7 from the bearing 7, and is provided with a driven wheel one 22, and the transmission belt 3 is disposed between the rotating roller 2 and the rotating roller 2, the rotating shaft. 4 The two ends pass through the bearing 7, and the driven wheel 2 25 is provided at one end of the rotating shaft 4, and the dial 24 is provided on the rotating shaft 4, and the bottom end of the dial 24 is placed in the positioni...

Embodiment 2

[0031] Append Figure 5 As shown: A cable protection tube production water-cooled system, including water tank 1, rotary roller 2, transmission belt 3, rotary shaft 4, top plate 5, and motor 6, characterized in that the water tank 1 is provided with bearing 7 The positioning groove 8 is provided on the inner wall of the water tank 1, and a fixing plate 9 is provided on the outer wall of the water tank 1, and a column 12 is provided at the top of the water tank 1, and the rotary roller 2 is provided with a connection. The shaft 21 is applied from the bearing 7 from the bearing 7, and is provided with a driven wheel one 22, and the transmission belt 3 is disposed between the rotating roller 2 and the rotating roller 2, the rotating shaft. 4 The two ends pass through the bearing 7, and the driven wheel 2 25 is provided at one end of the rotating shaft 4, and the dial 24 is provided on the rotating shaft 4, and the bottom end of the dial 24 is placed in the positioning groove 8, the Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com