Method for operating can changer, can changer and textile machine

A can replacement and changer technology, applied in the directions of transportation and packaging, transportation of filamentous materials, thin material processing, etc., can solve the problems of consumption structure and inability to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

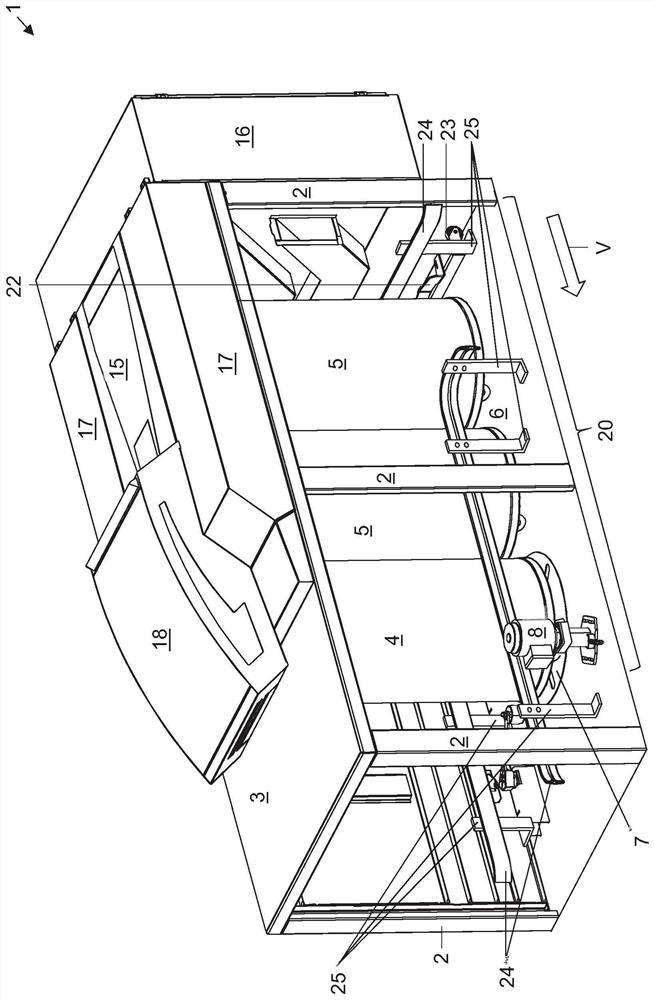

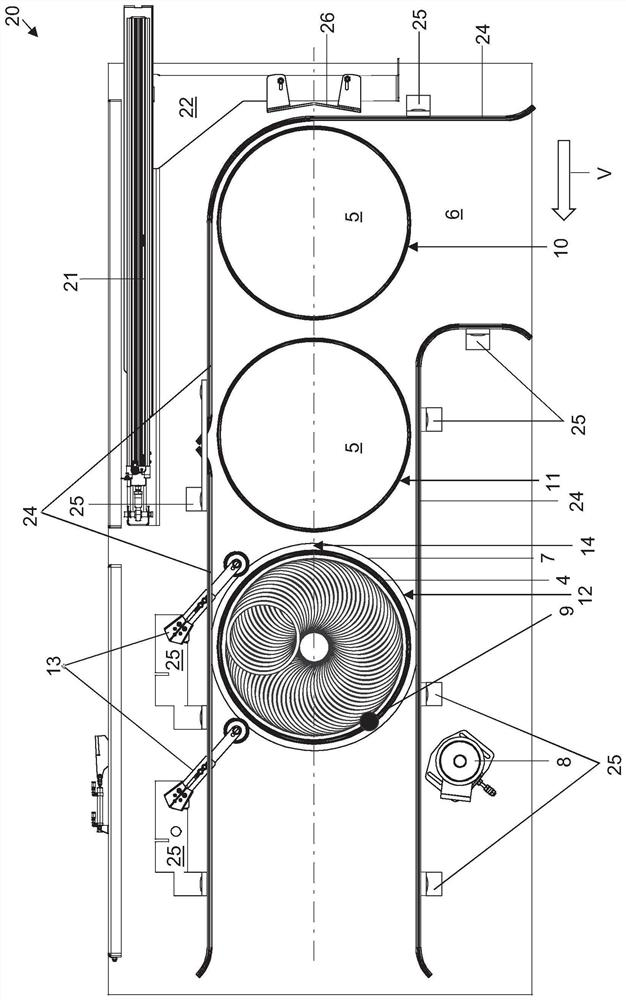

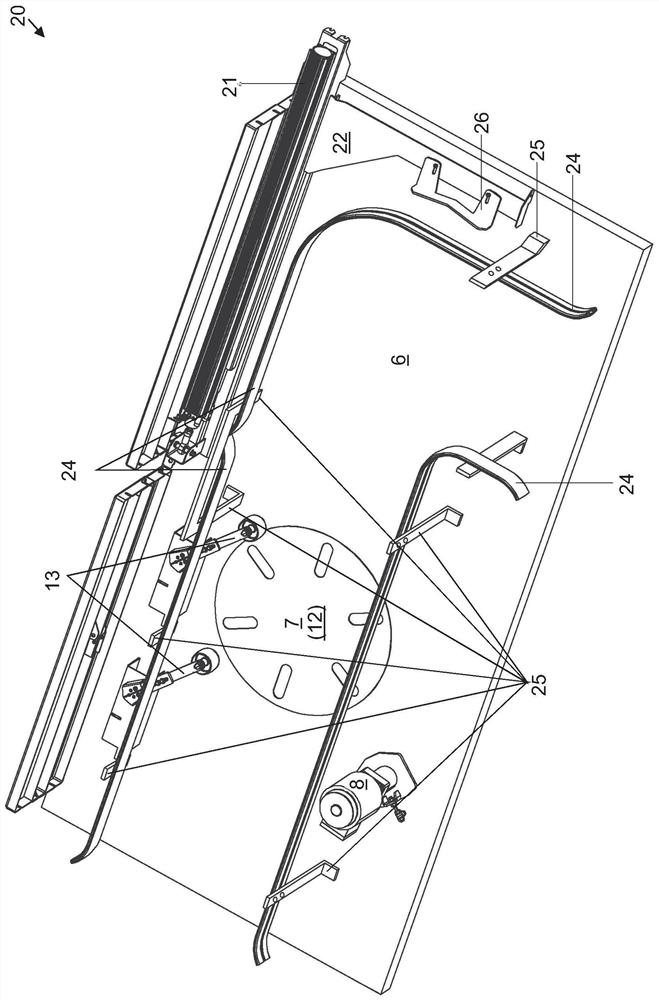

[0034] figure 1 A drawing frame 1 with a can changing section 20 according to one embodiment of the invention is shown. The draw frame 1 is designed here in a non-adjustable manner and includes a drawing section, not shown here, which is designed in a known manner.

[0035] The drafting section comprises a drafting mechanism hood 18 which covers the drafting mechanism and the can storage device located beneath it. Both of these are known and not described further.

[0036] Arranged upstream of the drafting unit in the processing direction V indicated by the square arrow is a feed table 15 via which the fiber sliver is fed from the cans via the creels into the drafting unit in the usual manner. On the side of the drafting mechanism cover 18 there is a side cover 17 which covers other components of the drawing frame 1 , such as drive belts, guide rollers of the drafting mechanism etc.

[0037] Upstream of the feed table 15 in the process direction V, the draw frame 1 preferab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com