Equipment for extracting metal zinc from waste batteries

A technology of used batteries and metal zinc, applied in the direction of improving process efficiency, can solve the problems of high energy consumption, low purity and large investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

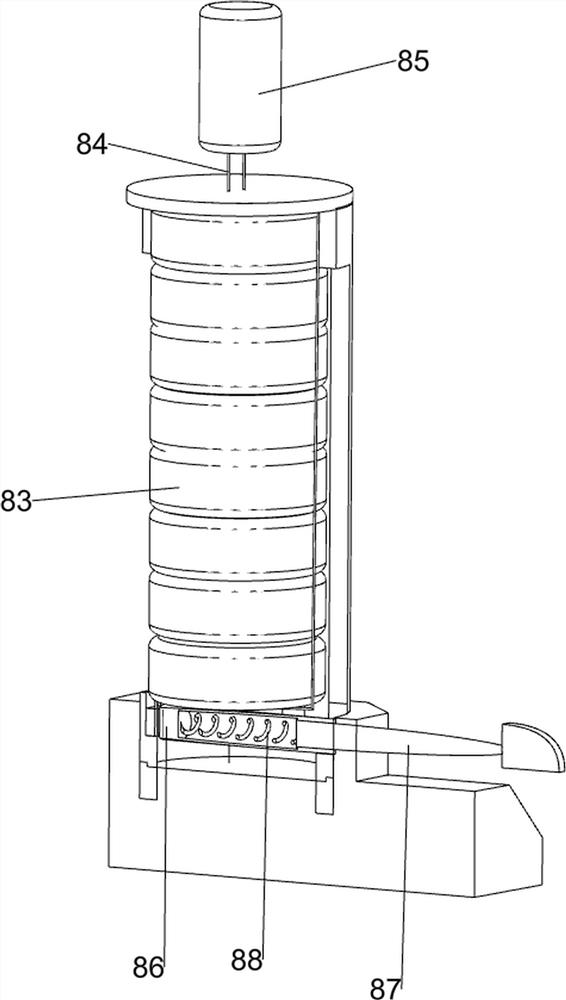

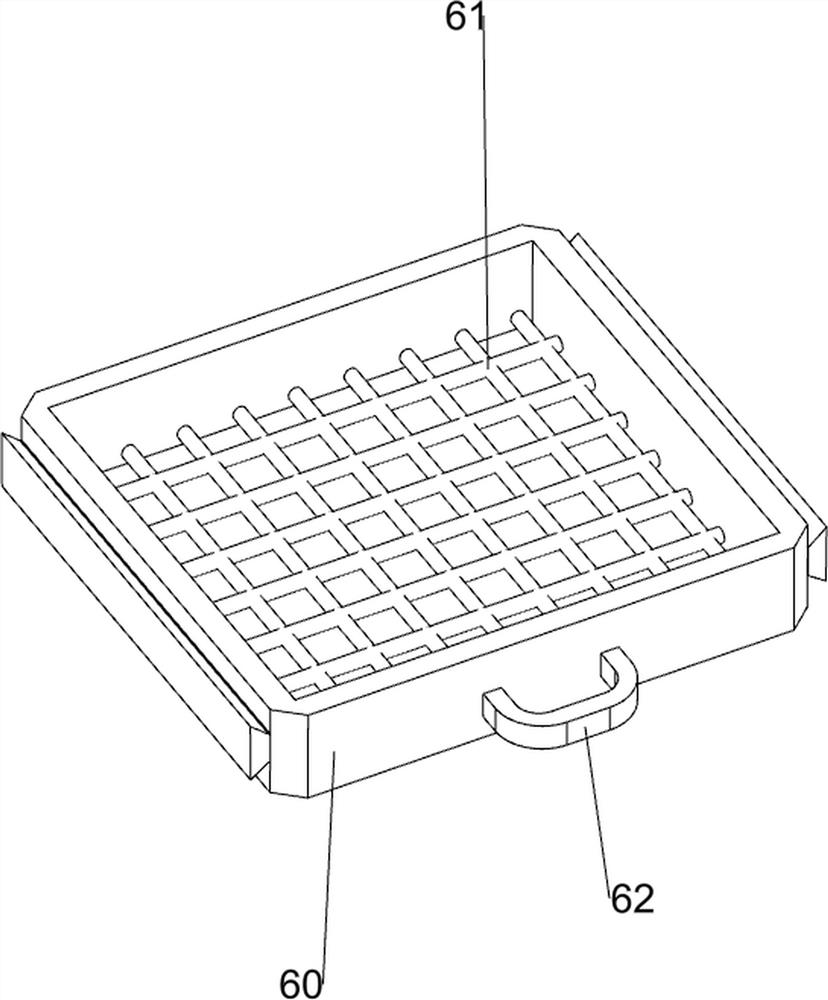

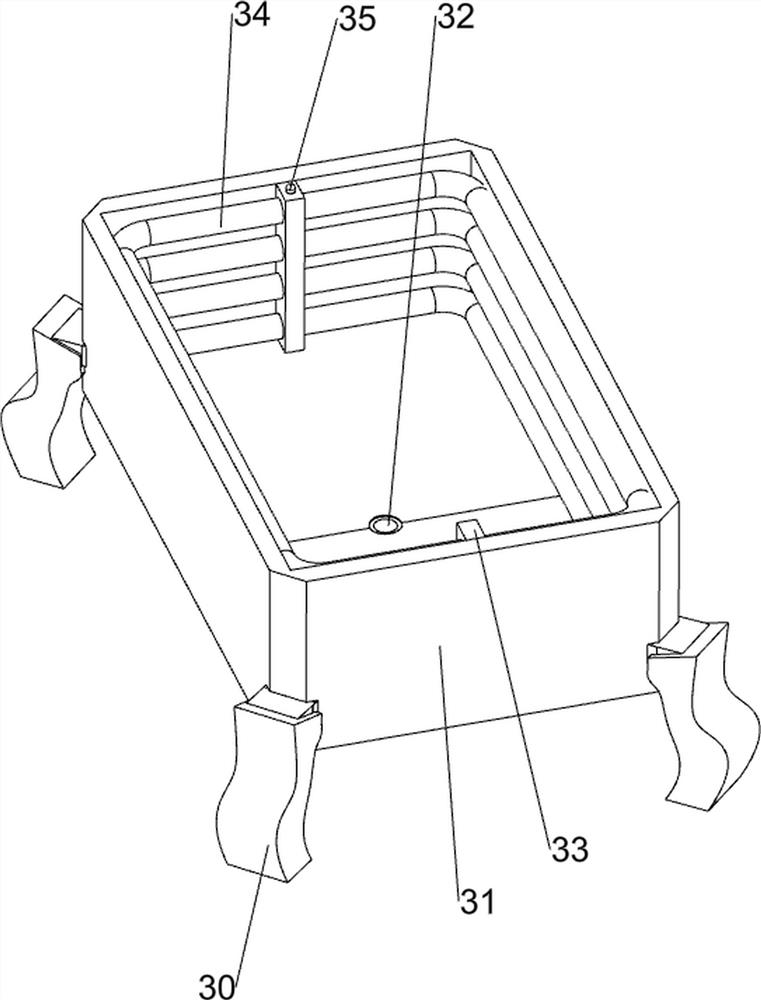

[0066] A kind of equipment for extracting metal zinc from waste batteries, such as figure 1 As shown, it includes a bottom plate 1, a bracket 2, a heating mechanism 3 and a crushing mechanism 4. The left side of the bottom plate 1 is connected with a bracket 2, the inner side of the bracket 2 is connected with a crushing mechanism 4, and the upper side of the bottom plate 1 is connected with a heating mechanism 3.

[0067] When the device needs to be used, the user can place multiple waste batteries in the crushing mechanism 4, and then start the crushing mechanism 4, so that the rear crushing mechanism 4 rotates forward, and then drives the front crushing mechanism 4 to reverse, so as to achieve the purpose of crushing waste batteries. The purpose is to make the waste battery move down to contact with the heating mechanism 3, press the heating mechanism 3 downward, so that the heating mechanism 3 starts to heat, and under the high temperature of the heating mechanism 3, the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com