Method for separating and recovering product oil from waste lubricating oil and device thereof

A waste lubricating oil, separation and recovery technology, applied in the direction of lubricating composition, etc., to achieve the effect of low vacuum degree, fast rectification speed and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1 Using multiple intervals to separate and recover finished oil from waste mixed lubricating oil

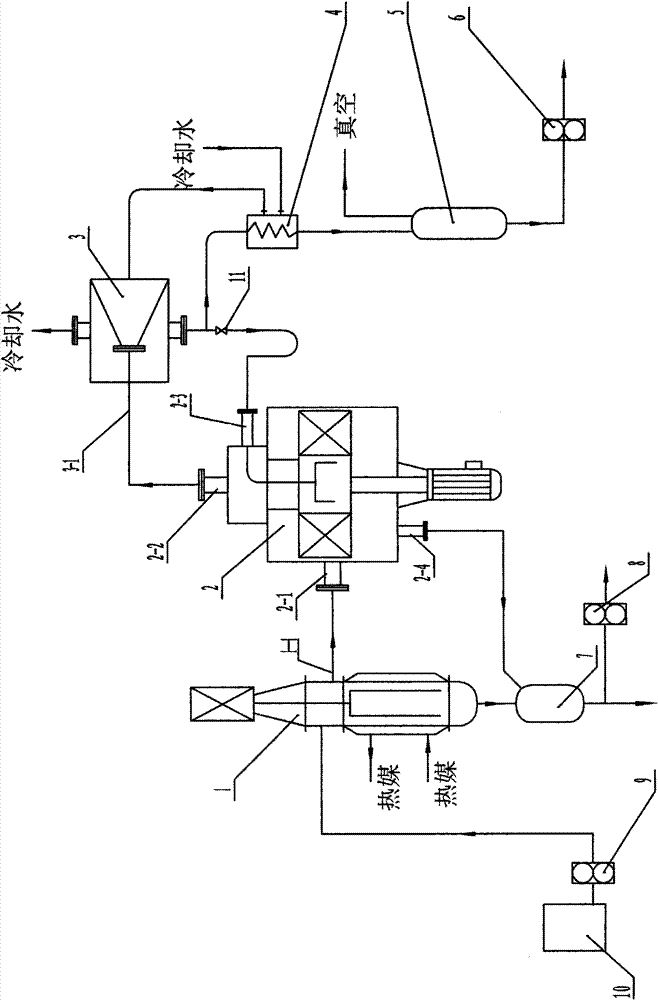

[0042] Production equipment flow such as figure 1 Shown:

[0043] The waste lubricating oil is input into the raw material tank 10, and the waste lubricating oil is pumped into the wiped film evaporator 1 through the material pump 9 for heating. The tangential direction of the shell enters the inlet pipe 2-2 of the rotary bed, and the mass transfer through the packing layer enters the inlet pipe 3-1 of the condenser from the supergravity of the supergravity rotary bed 2, and the gas is condensed into liquid by the condenser 3, and the condensate Controlled by the reflux regulating valve 11, a part is returned to the rectifier as reflux liquid through the central return pipe of the supergravity packed bed 2, and the other part enters the finished product tank 5 through the cooler 4, and is discharged as a finished product by the discharge pump 6; The bottom of the...

Embodiment 2

[0049] Example 2 Using two-stage continuous distillation to separate and recover refined oil from waste gear oil

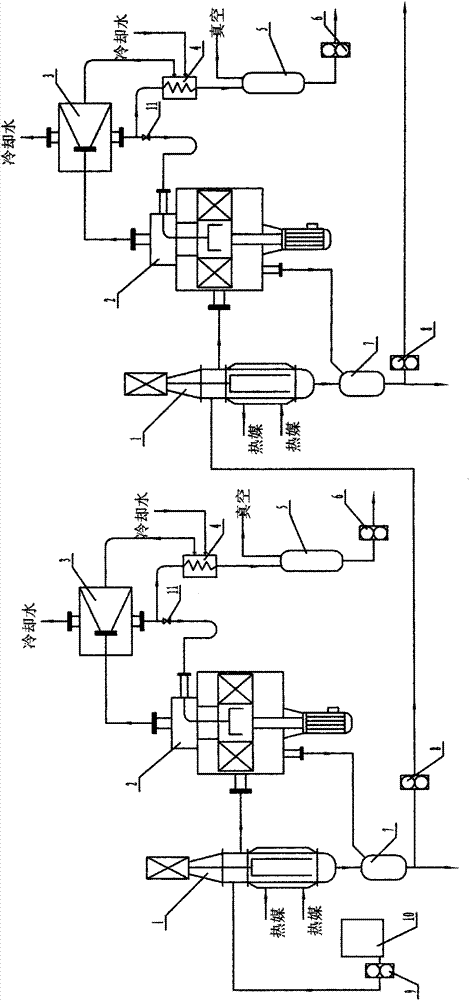

[0050] Such as figure 2 Shown:

[0051] 1. 100Kg of waste gear oil pretreated by dehydration and removal of mechanical impurities, stored in the raw material tank T1;

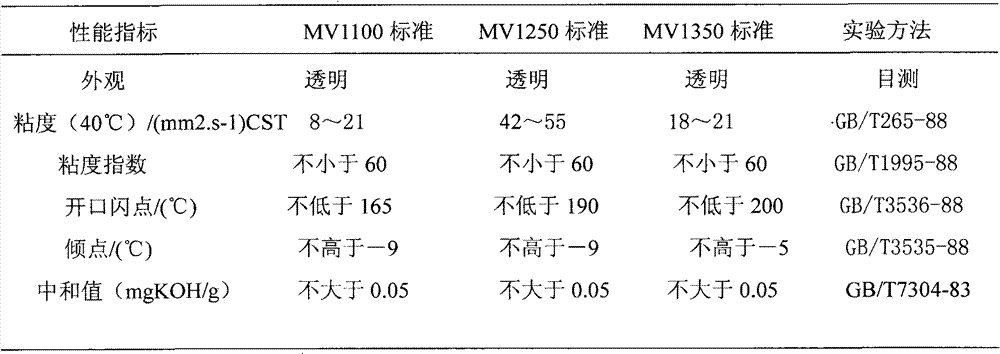

[0052] 2. Continuously pump the raw material into the first-stage wiped film evaporator 1 through the material pump 9, and heat it through the heat medium in the interlayer. The heating temperature of the wiped film evaporator 1 is set at 210±10°C, and the vacuum degree of the system is absolute pressure 5Pa, the high-gravity packing rotating field bed 2 rectifies the base oil components, enters the finished product tank 5, and is discharged by the material pump 6. The output volume is 43.7 kg, and the viscosity and flash point meet the technical indicators of MV1100 base oil;

[0053] 3. The remaining heavy components through the first stage rectification enter the heavy component receiving tan...

Embodiment 3

[0054] Example 3 Adopt three-stage continuous distillation to separate and recover refined oil from internal combustion engine oil

[0055] Such as figure 2 As shown, but after the material pump is connected to a three-stage continuous rectification device composed of a wiped film evaporator and a high-gravity packed rotating field bed.

[0056] 1. 100Kg of internal combustion engine oil through dehydration and mechanical impurity pretreatment is stored in the raw material tank 10;

[0057] 2. Continuously pump the raw material into the first-stage wiped film evaporator 1 through the material pump 9, and heat it through the heat medium in the interlayer. The heating temperature of the wiped film evaporator 1 is set at 185±5°C, and the vacuum degree of the system is absolute pressure 80Pa, the high-gravity packing rotary field bed 2 rectifies the base oil components, enters the finished product tank 5, and discharges it from the material pump 6. The output is 5.7 kg, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com