Clothes processing equipment

A technology of clothing processing equipment and valve core, which is applied to other washing machines, washing machines with containers, washing devices, etc., can solve the problems of inability to achieve drainage, overloaded operation of motors, etc., and achieves simple structure, improved service life, and high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

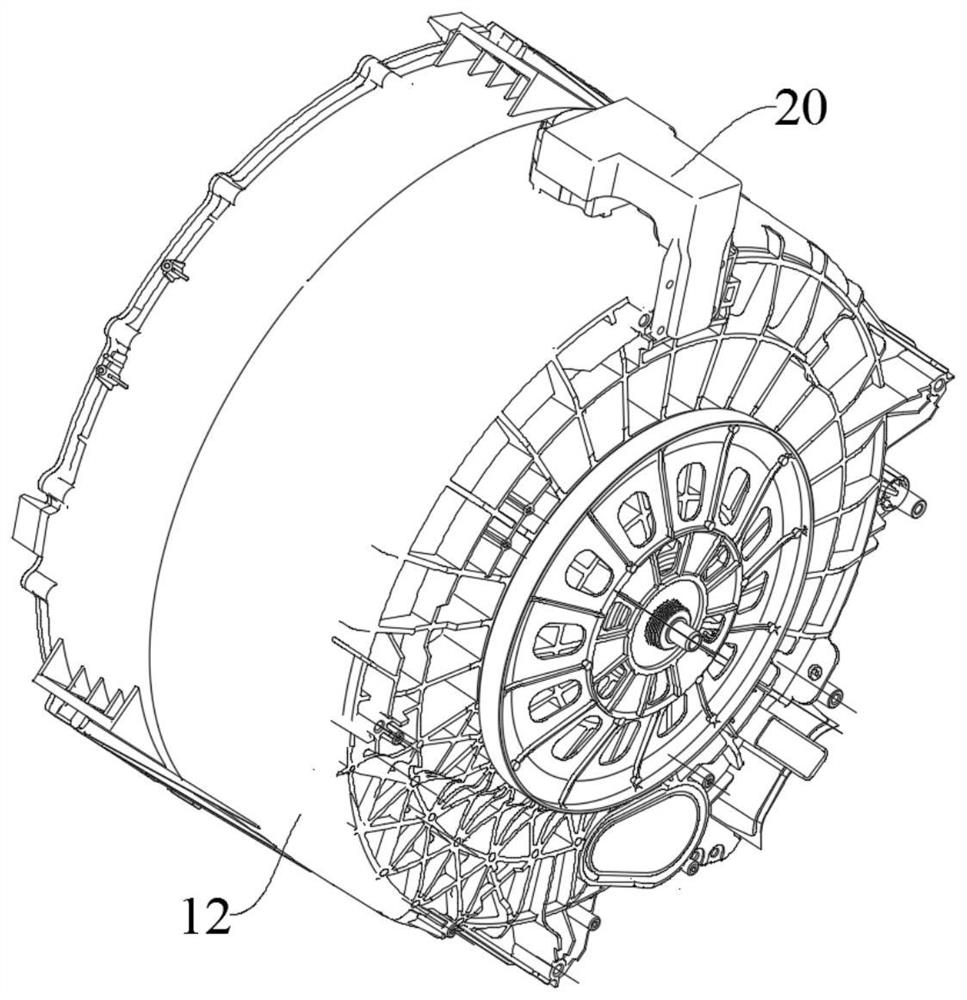

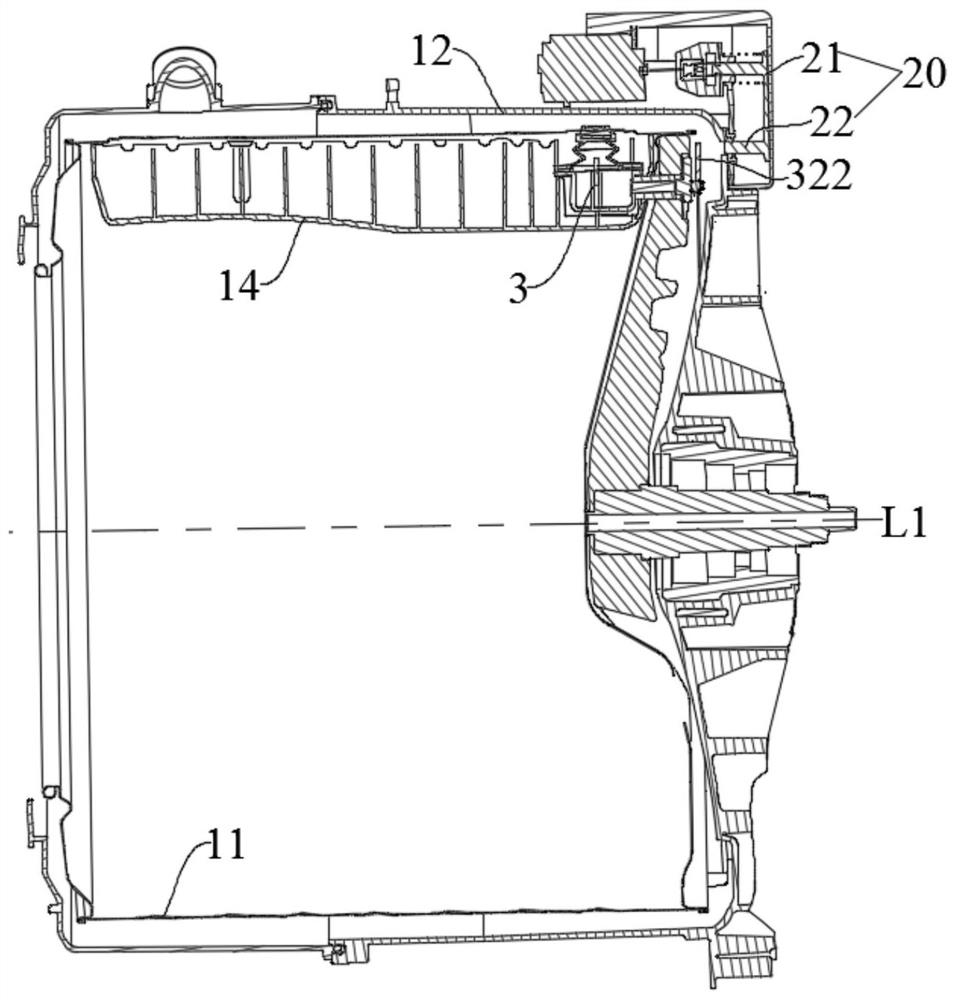

[0112] see Figure 8 to Figure 16 ,, In this embodiment, the transmission rod mechanism 32 drives the spool 31 assembly to move in translation.

[0113] The drain valve assembly 3 includes the above-mentioned transmission rod mechanism 32 , valve seat 35 , valve core 31 , flexible seal 36 , reversing mechanism 323 , first torsion spring 33 and second torsion spring 34 .

[0114] The first torsion spring 33 is sleeved on the transmission rod 321 . The first end of the transmission rod 321 has a flat shaft portion 3211 . The second end of the transmission rod 321 is socketed with the first driving rod 322 and can realize synchronous rotation.

[0115] The turntable 3231 is formed with a through hole 3231c, and the inner wall of the through hole 3231c is provided with two rotationally symmetrical protrusions 32311, and the two protrusions 32311 separate part of the space of the through hole 3231c into two first driving grooves 3231a distributed along the circumferential directi...

no. 2 example

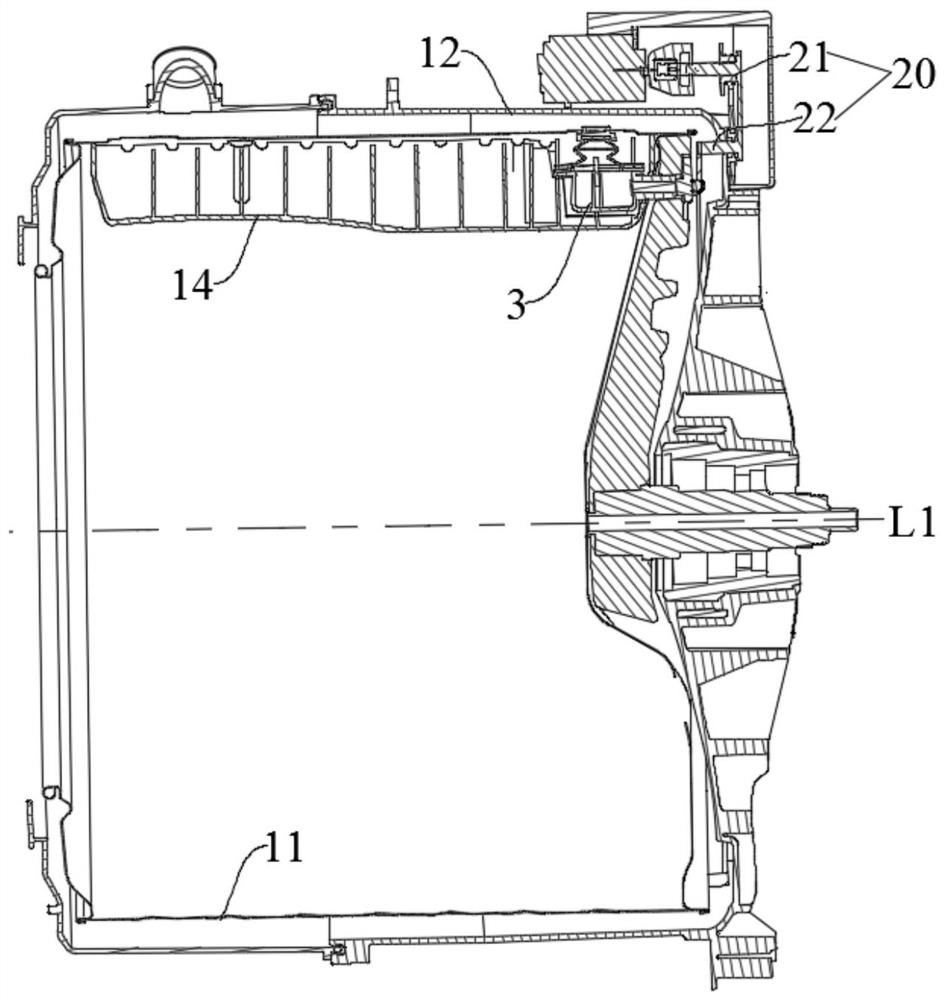

[0121] see Figure 17 to Figure 21 Most of the structures of the embodiment of the present application are substantially the same as those of the first embodiment, the differences include: the structure of the second end of the transmission rod 321 , the structure of the reversing mechanism 323 , and the connection position of the second torsion spring 34 .

[0122] Specifically, the turntable 3231 is formed with a through hole 3231c, and the first driving groove 3231a passes through a part of the side wall of the through hole 3231c along the radial direction of the through hole 3231c, that is to say, the first driving groove 3231a is roughly in the shape of a gap, and the transmission rod 321 A protruding block 3212 is provided on the surface of the body, the transmission rod 321 is passed through the through hole 3231c, and the protruding block 3212 is located in the first driving groove 3231a.

[0123] The second torsion spring 34 and the reversing mechanism 323 are dispose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com