Water surface garbage collecting device

A collection device and water surface garbage technology, which is applied to the cleaning of open water surfaces, water conservancy projects, construction, etc., can solve the problems of reduced work efficiency, time consumption of salvagers, time-consuming and labor-intensive problems, and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

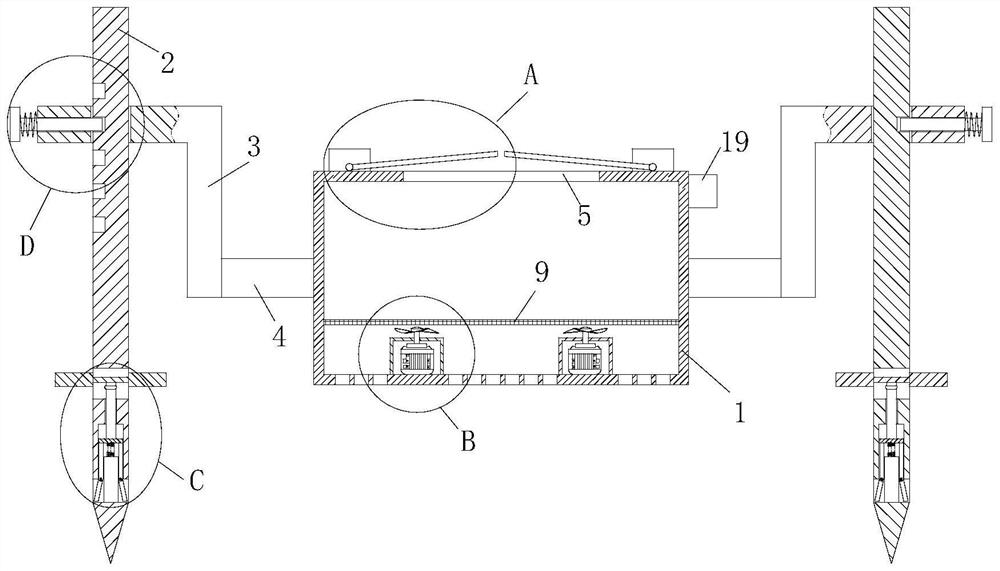

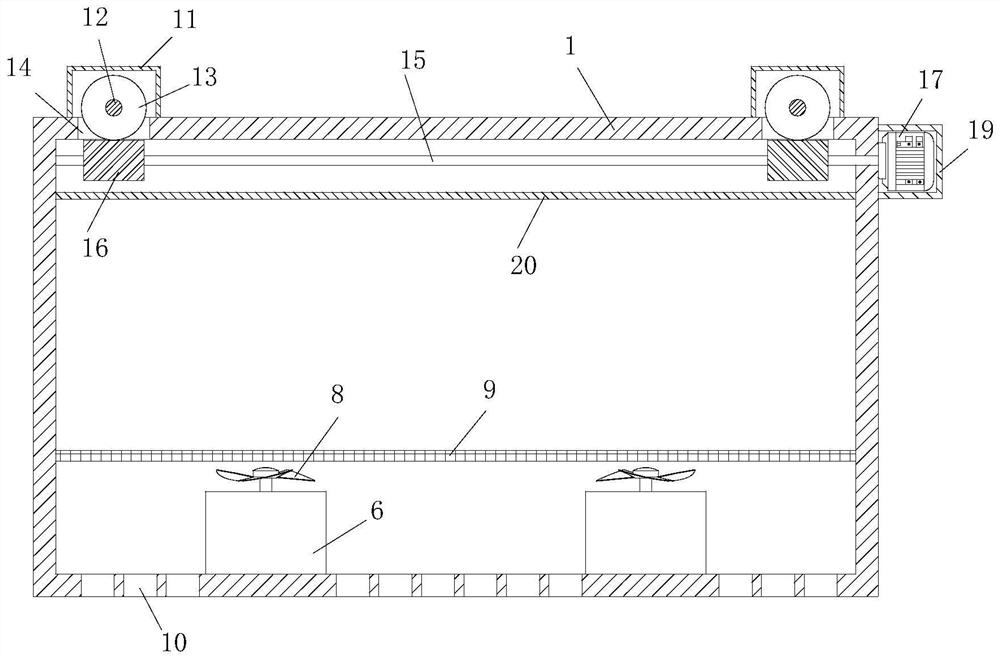

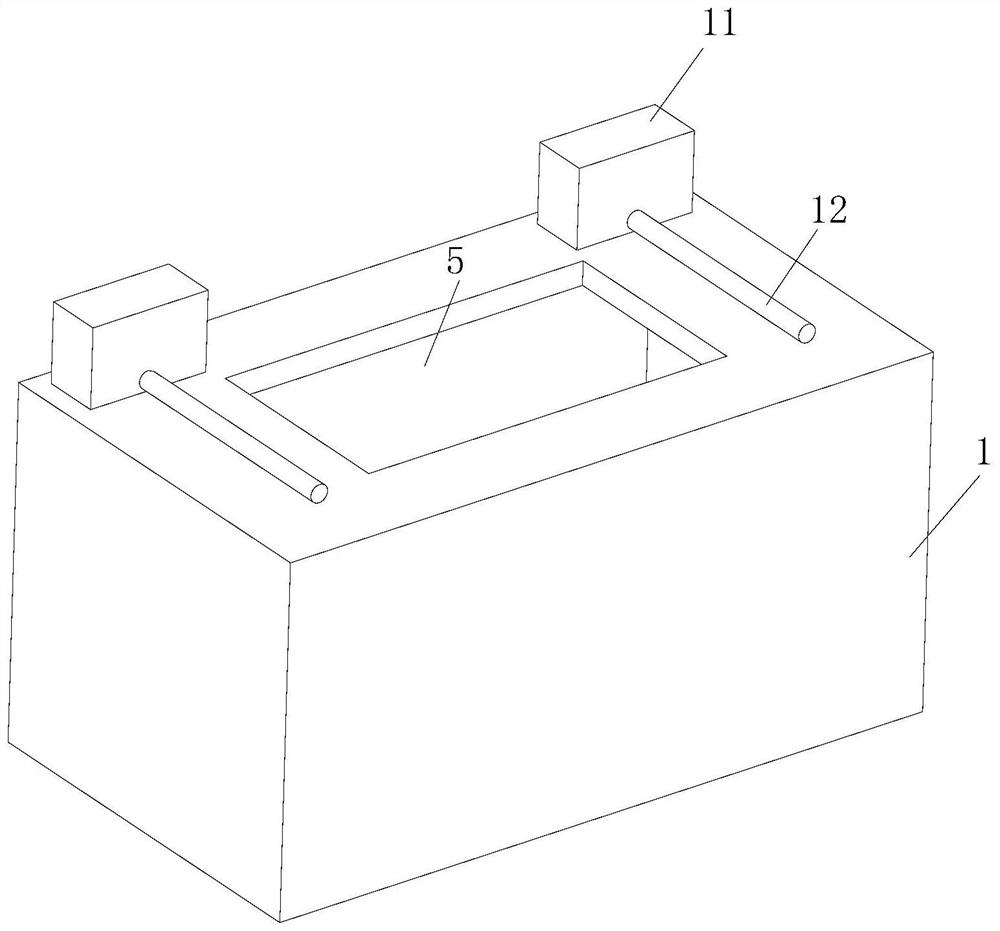

[0029] see Figure 1-7As shown, a water surface garbage collection device includes a collection box 1, a mounting rod 2, an L-shaped plate 3 and a connecting rod 4; the connecting rod 4 is fixed on the left and right sides of the collecting box 1; the L-shaped plate 3 Sleeved and slidably connected to the installation rod 2, and one end of the connection rod 4 is fixedly connected to one side of the L-shaped plate 3; the installation rod 2 is inserted on the ground; the top of the collection box 1 is provided with a feeding port 5. The bottom inner wall of the collection box 1 is fixed with a protective shell 6, the bottom inner wall of the collection box 1 is fixed with a turbine motor 7, and the turbine motor 7 is located inside the protective shell 6, and the turbine motor The output shaft of 7 is fixedly connected with turbine blade 8, and turbine blade 8 is positioned at the outside of protective shell 6; The inner wall of described collection box 1 is fixed with filter s...

Embodiment 2

[0038] see Figure 8 As shown, compared with Example 1, as another embodiment of the present invention, the opening of the third through groove 28 is fixed with elastic cloth 35, the second plate 29 penetrates through the elastic cloth 35, and the second rod 15 and the elastic cloth 35 are affixed; during work, through the elastic cloth 35, the third through groove 28 is in a closed state, which can prevent foreign matter from entering the third through groove 28, and then will not affect the normal sliding of the second plate 29, Also can not influence the normal sliding of push rod 27.

[0039] Working principle: Move the device to the downstream position of a small river, choose a position with a small river width, insert the installation pole 2 into the soil on both sides of the river, and then push the push plate 30 downward, so that the push plate 30 drives the second The plate 29 slides down along the third slot 28, and then the push rod 27 squeezes the No. 1 plate 22,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com