Fabricated wallboard connecting mechanism based on fabricated building

A connecting mechanism and assembly technology, applied in building components, building structures, buildings, etc., can solve the problems of inconvenient installation and the inconvenient way of quasi-reserved pipe sockets, and achieve the effect of convenient and rapid installation and accelerated solidification. , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

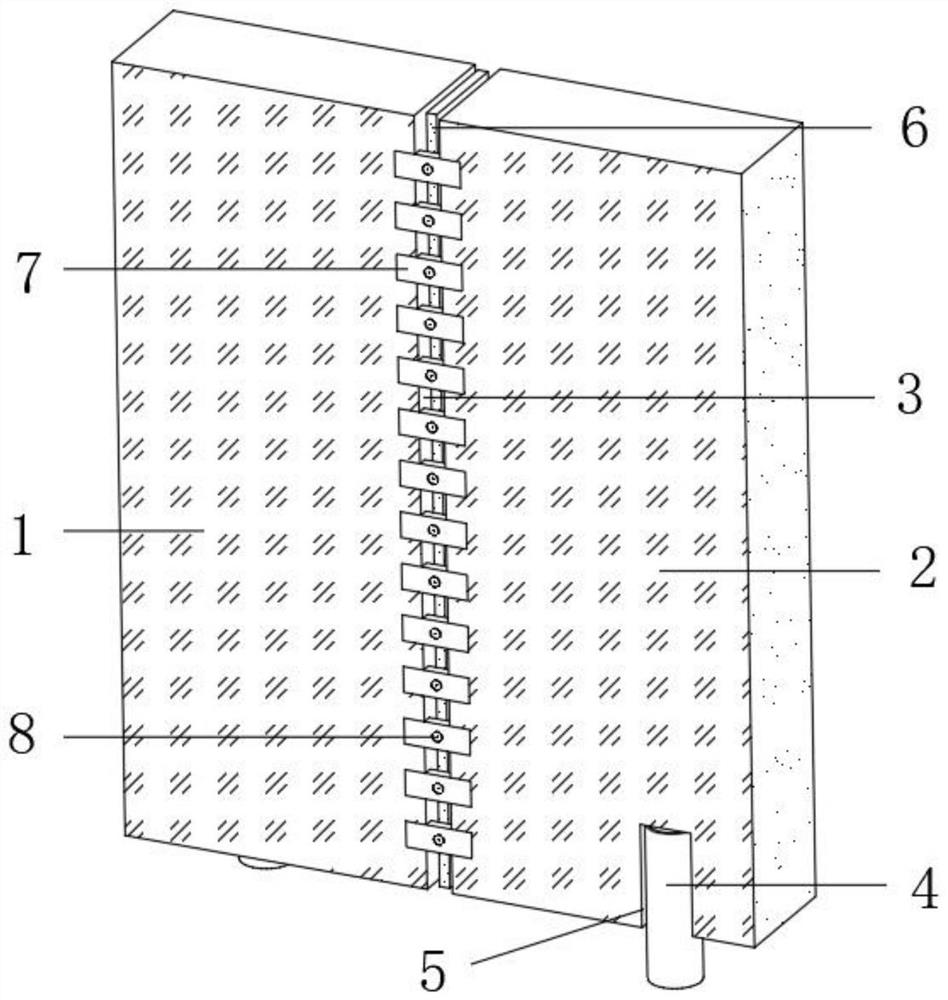

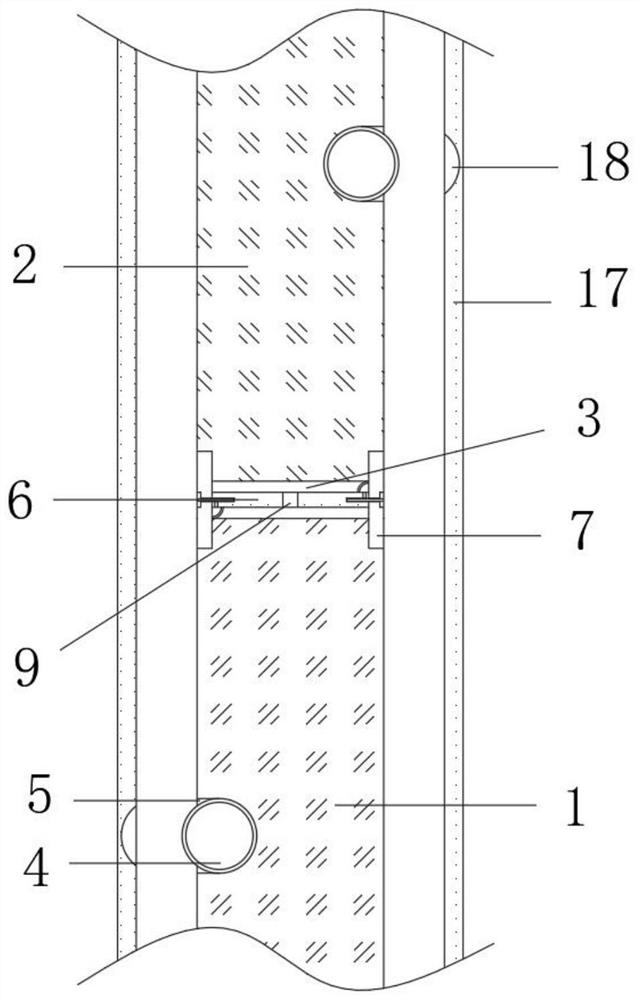

Embodiment 1

[0032] refer to Figure 1-Figure 7 , an assembly wall panel connection mechanism based on prefabricated buildings, including two sets of wall panels, embedded pipes 4 and a connection mechanism, the two sets of wall panels are respectively set as the first wall panel 1 and the second wall panel 2, and the first A gap cavity 3 is provided between the wall panel 1 and the second wall panel 2, and a connection mechanism that can be inserted horizontally is provided in the gap cavity 3, and concrete is poured in the gap cavity 3 after the connection mechanism is inserted, and the first wall panel 1 and the second wall panel The bottom end of the outer wall at the opposite end of the wallboard 2 is provided with a connecting groove 5, and the connecting groove 5 is compatible with the embedded pipe 4, and the two ends of the wallboard are provided with a panel 17 covering the embedded pipe 3. In actual use, from Move the two groups of wall panels in the panel direction of the wall ...

Embodiment 2

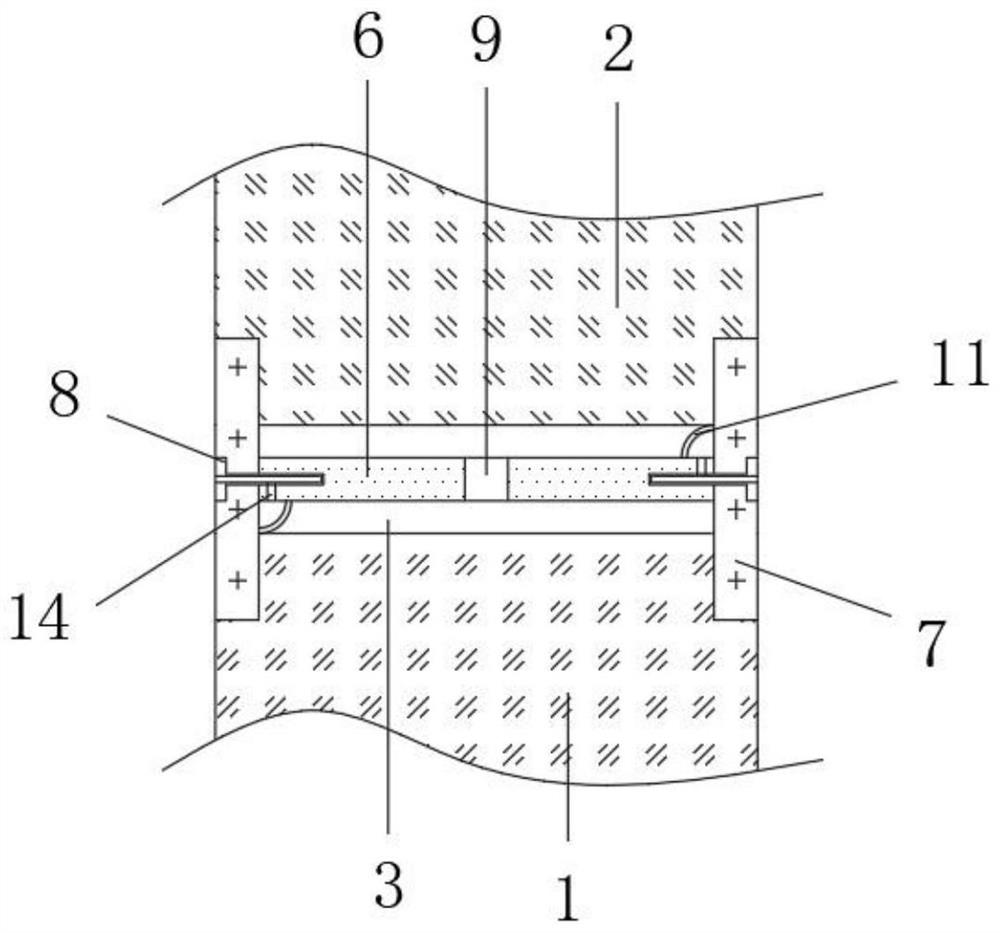

[0039] refer to figure 1 and Figure 8-Figure 9 , an assembly wall panel connection mechanism based on a prefabricated building, including two sets of wall panels, embedded pipes 4 and a connection mechanism, the two sets of wall panels are respectively set as the first wall panel 1 and the second wall panel 2, and the second A gap cavity 3 is provided between the first wall panel 1 and the second wall panel 2, and a connecting mechanism that can be inserted horizontally is arranged in the gap cavity 3, and concrete is poured in the gap cavity 3 after the connecting mechanism is inserted, the first wall panel 1 and the second wall panel The bottom end of the outer wall at the opposite end of the two wallboards 2 is provided with a connecting groove 5, and the connecting groove 5 is compatible with the embedded pipe 4, and the two ends of the wallboard are provided with a panel 17 covering the embedded pipe 3, and the connecting groove 5 is vertical. The inner side of the stra...

Embodiment 3

[0043] Embodiment 3 includes all structures and methods of embodiment 1 and implementation 2, with reference to Figure 1-Figure 10 , an assembly wall panel connection mechanism based on a prefabricated building, further includes an auxiliary groove 22 provided on the outer wall of one end of the limit block 20, and the bottom end of the auxiliary groove 22 is penetrated, and the auxiliary groove 22 is close to a side of the connection mechanism. The side inner wall is set as an inclined surface, and the side of the auxiliary groove 22 away from the connecting mechanism is set as a vertical surface, and the width of the auxiliary groove 22 gradually increases from top to bottom, so that the wallboard is first leaned against when the wallboard is connected and installed. Fix the connecting mechanism on the corresponding pre-embedded pipe 4, and then pour concrete from the top into the gap cavity 3, and then pour concrete into the pre-buried pipe 4 to the limit when the concrete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com