Automatic separation equipment for peel and pulp of holboellia latifolia

A technology for automatic separation and peeling of melons and fruits, which is applied in the fields of vegetable or fruit peeling, food science, application, etc., and can solve the problems of time-consuming and labor-intensive separation of August melon pulp and peel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

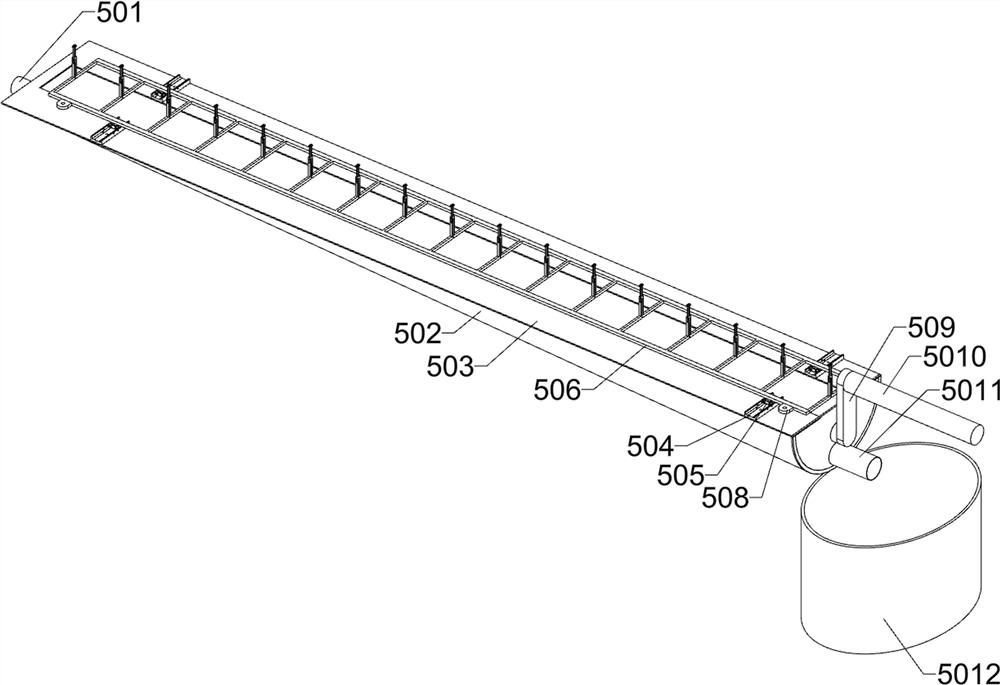

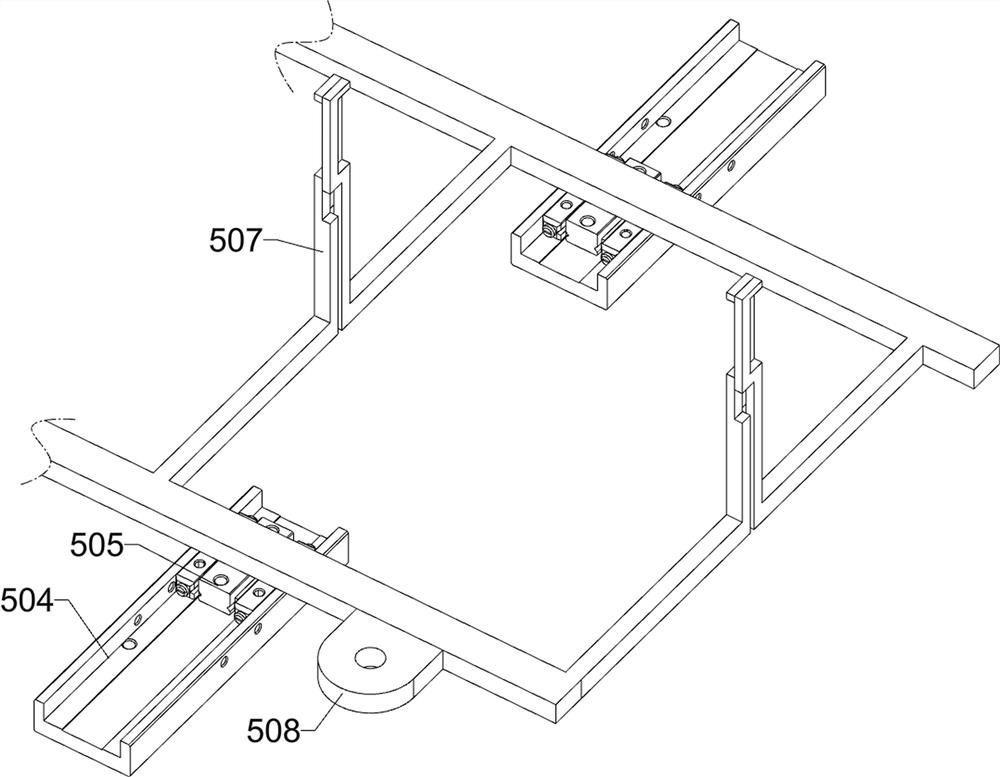

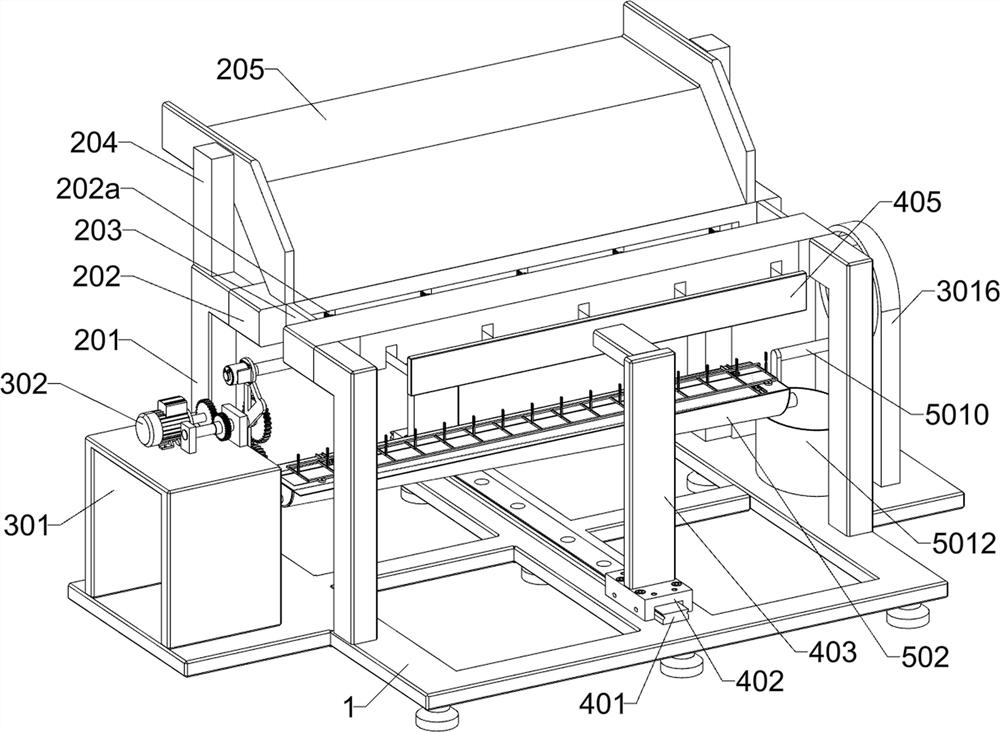

[0031] A kind of automatic separation equipment of August melon peel and pulp, such as Figure 1-10 As shown, it includes an installation base 1, a feeding system 2, a transposition control system 3, a fruit clamping system 4 and a pulp collection system 5; the upper four corners of the installation base 1 are equipped with a feeding system 2; the installation base 1 The transposition control system 3 is installed on the upper left part and the upper right part, and the transposition control system 3 is located on both sides of the feeding system 2; the fruit clamping system 4 is installed in the upper middle part of the installation chassis 1; the transposition control system 3 is connected with pulp collection system 5.

[0032] Working principle: When starting to work, the operator puts the August melon from the upper side of the feeding system 2, so that the August melon falls on the upper side of the transposition control system 3, controls the transposition control syste...

Embodiment 2

[0040] Embodiment 2 is on the basis of embodiment 1, as figure 1 and Figure 11-12 As shown, a pulp extruding system 6 is also included, and the upper front part of the installation base frame 1 is connected with the pulp extruding system 6, and the pulp extruding system 6 includes a third installation frame 601, a second limiting plate 602, a third Mounting plate 603, first roller 604, second roller 605, third roller 606, fourth roller 607, rope 608, fourth mounting plate 609, second connecting column 6010 and peel extrusion block 6011; install on the chassis 1 A third mounting frame 601 is welded on the front side of the side; two second limiting plates 602 are fixedly connected to the upper rear of the third mounting frame 601, and the two second limiting plates 602 are symmetrically distributed left and right; A limit chute 602a is respectively opened on the lower part of the opposite side of the limit plate 602; two third mounting plates 603 are fixedly connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com