Roving frame with dust collection function

A roving frame and functional technology, applied in the field of textile processing, can solve the problems affecting the breathing health of workers, achieve the effect of improving the health of the body, improving the working environment, and improving the cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

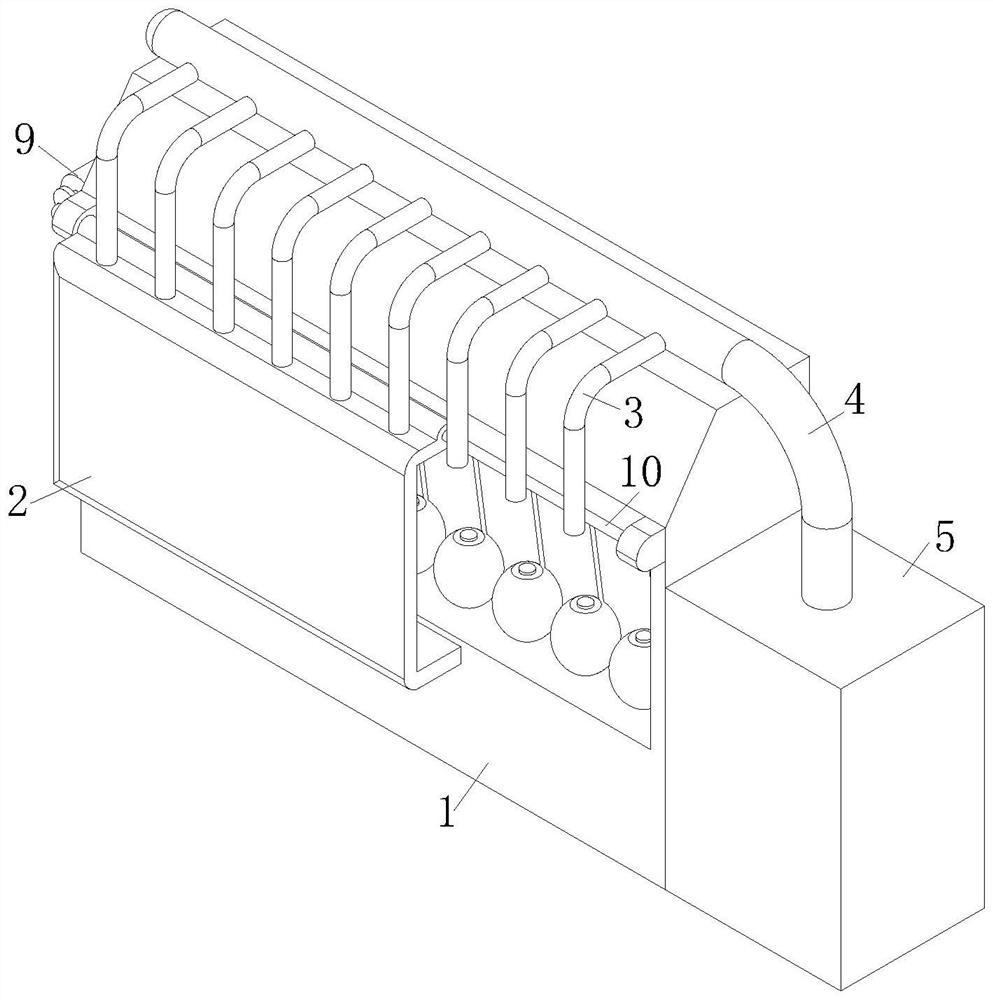

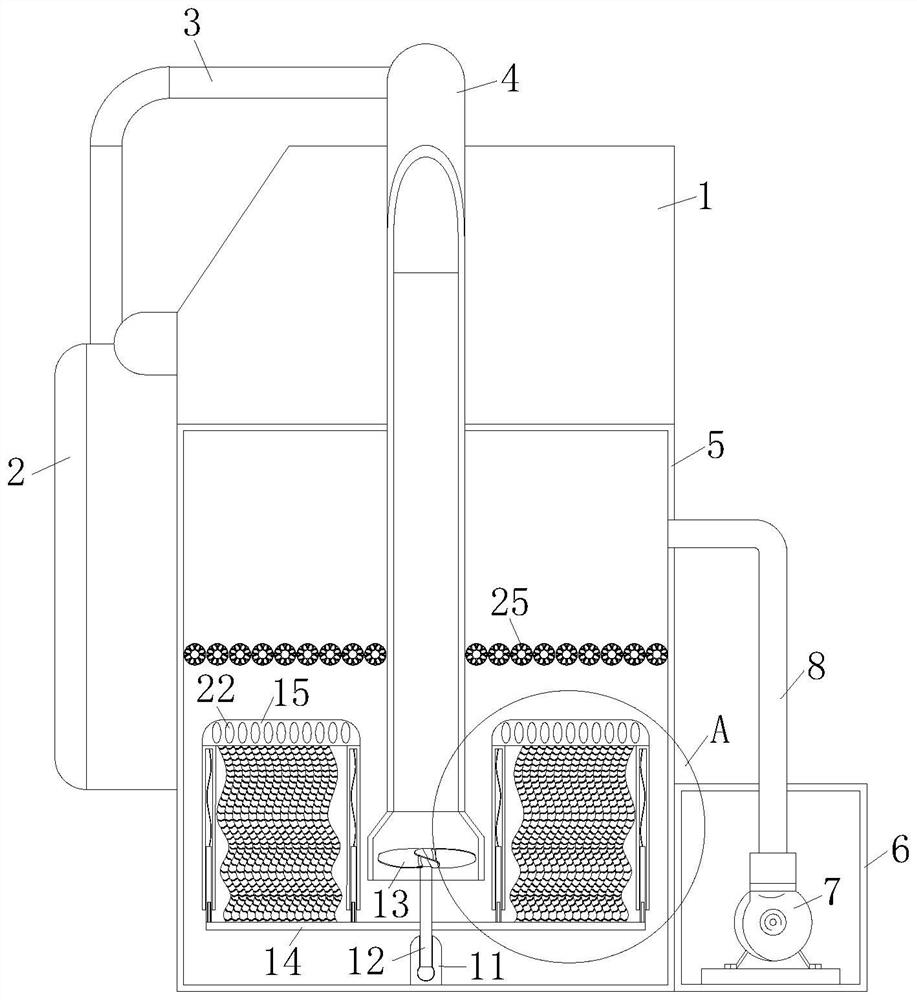

[0031] Such as Figure 1 to Figure 2As shown, a roving frame with dust suction function described in the embodiment of the present invention includes a roving frame 1, a collection cover 2, a No. 1 pipe 3, a No. 2 pipe 4, a filter box 5, an equipment box 6, and an air suction pump 7 and No. 3 pipe 8; the outer wall of the spinning place of the roving frame 1 is equipped with a collecting cover 2, and the top of the collecting cover 2 is connected to a plurality of No. 1 pipes 3, and the top wall of the roving frame 1 is fixedly connected to the No. 2 pipe 4. The No. 1 pipe 3 is connected to the No. 2 pipe 4, the side wall of the roving machine 1 is fixedly connected to the filter box 5, the inside of the filter box 5 is filled with clean water, and the bottom end of the No. 2 pipe 4 runs through The top wall of the filter box 5, and the outer wall of the No. 2 pipe 4 is affixed to the top wall of the filter box 5. The bottom end of the No. 2 pipe 4 is located below the liquid ...

Embodiment 2

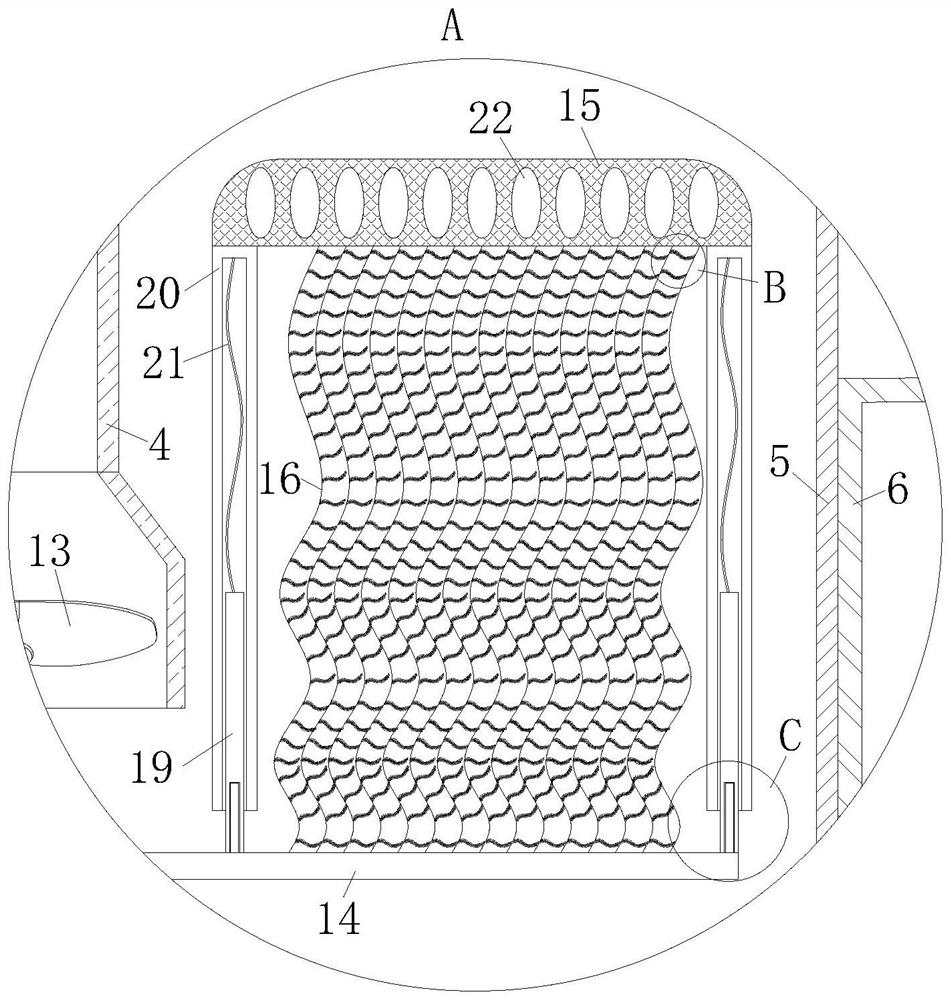

[0041] Such as Figure 7 As shown in Comparative Example 1, another embodiment of the present invention is as follows: the top of the No. The interior of the wedge-shaped ring plate 30 is fixed with a magnet 31, and the magnet 31 is attracted to the magnetic ball 26. The inner wall of the wedge-shaped ring plate 30 is fixed with a plurality of sealing rings; during work, as the liquid level rises, it drives The hollow floating ball 25 rises, and when the liquid level is close to the water blocking pipe 29, the hollow floating ball 25 is sucked into the wedge-shaped ring under the action of the suction force generated by the suction pump 7 and the attraction force between the magnet 31 and the magnetic force ball 26. The inside of the plate 30 makes the hollow floating ball 25 and the sealing ring deform and fit together, preventing the clear water in the filter box 5 from being sucked into the suction pump 7, thereby further improving the working safety of the suction pump 7. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com