Wet type granulator beneficial to stirring and chopping

A technology of wet granulator and stirring spindle, which is applied in the direction of granulation in static tanks/tanks, can solve the problems of reducing the use effect of the overall structure, low stirring and cutting efficiency, and material accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

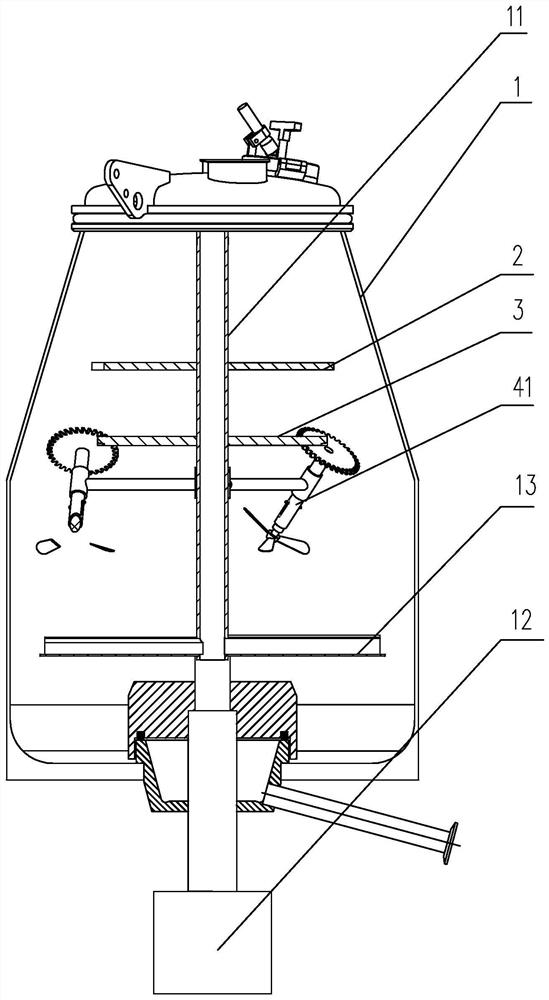

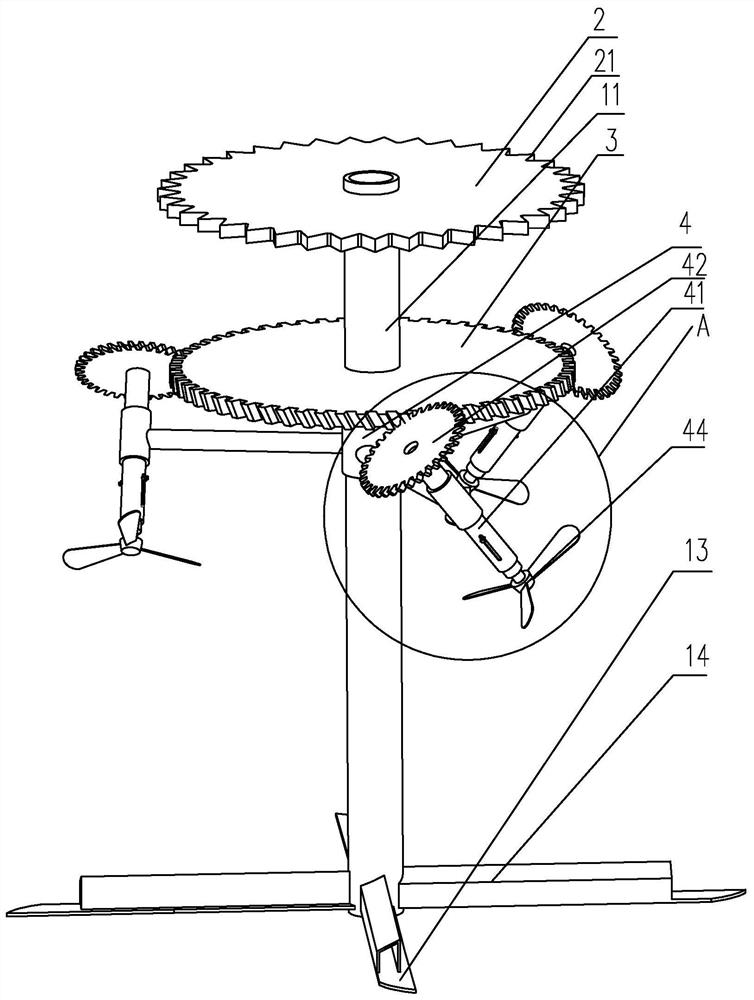

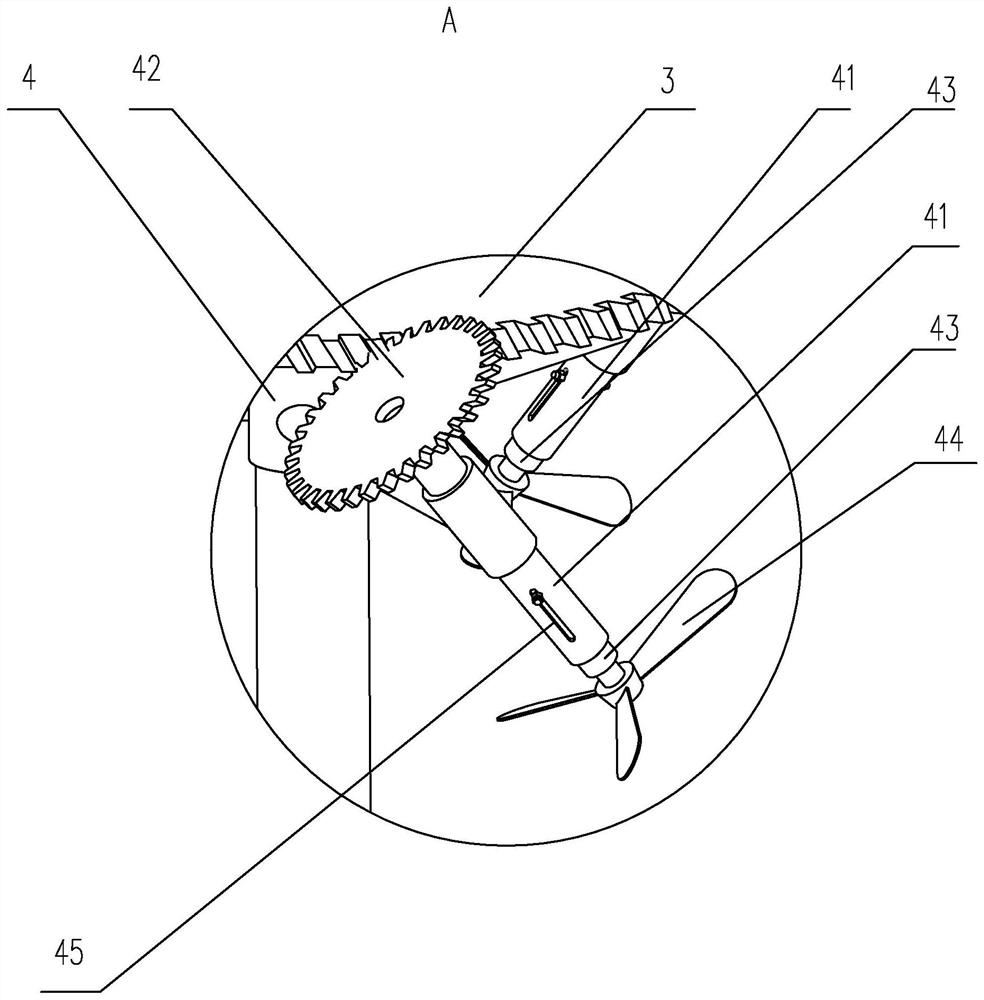

[0017] The present invention is beneficial to the embodiment of the wet granulator of mixing chopping such as Figure 1 to Figure 3 As shown: it includes a body 1, the body 1 is provided with a stirring main shaft 11 and a drive motor 12 for controlling the rotation of the stirring main shaft 11, and the stirring main shaft 11 is provided with a flat tooth disc 2 and a driving gear 3, and the stirring The main shaft 1 is rotatably provided with a connection seat 4, and the connection seat 4 is rotatably provided with several driven rods 41, the driven rods 41 are arranged obliquely, one end of the said driven rod 41 is provided with a dispersion blade 44, and the other There is a driven gear 42, and the driven gear 42 meshes with the driving gear 3 to drive the driving gear 3 to rotate the driven rod 41. The end of the stirring main shaft is obliquely provided with stirring blades 13. The beneficial effect of such setting is: such setting, the driving motor drives the stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com